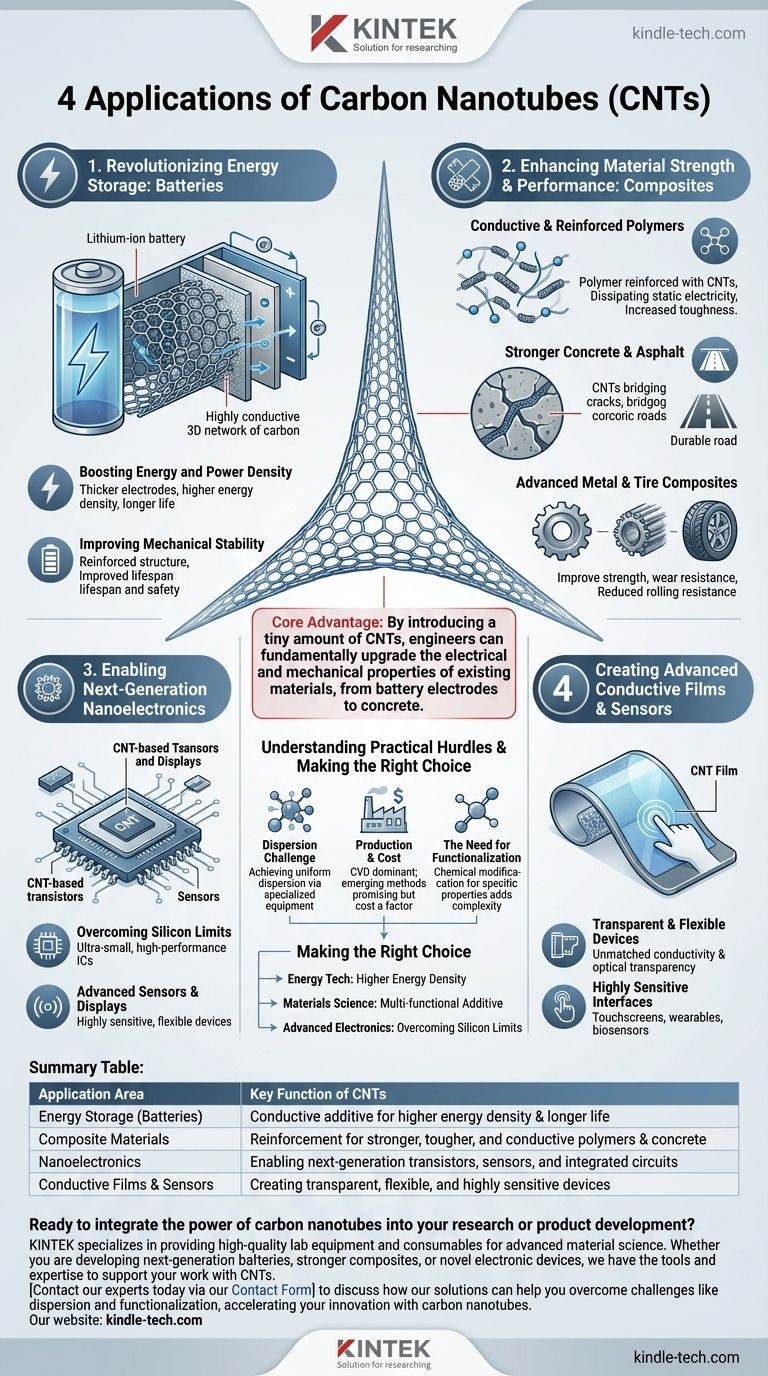

At their core, carbon nanotubes (CNTs) are applied in four primary domains: enhancing lithium-ion batteries, reinforcing composite materials, enabling next-generation nanoelectronics, and creating advanced conductive films and sensors. Their unique, needle-like structure provides an unmatched combination of electrical conductivity, mechanical strength, and a high aspect ratio, making them a powerful additive for improving material performance.

The true significance of carbon nanotubes is not just their list of uses, but their function as a foundational enabling material. By introducing a tiny amount of CNTs, engineers can fundamentally upgrade the electrical and mechanical properties of existing materials, from battery electrodes to concrete.

Revolutionizing Energy Storage: The Role in Batteries

The most significant commercial application for carbon nanotubes today is in energy storage, specifically as a conductive additive in lithium-ion battery electrodes.

Boosting Energy and Power Density

CNTs create a highly efficient, three-dimensional conductive network within the battery's cathode and anode. This allows electrons to move more freely, dramatically increasing the electrode's overall conductivity.

This enhanced conductivity enables the design of thicker electrodes without sacrificing performance. Thicker electrodes can hold more active material, directly translating to higher energy density and longer battery life for devices and electric vehicles.

Improving Mechanical Stability

The inherent strength and flexibility of CNTs also provide mechanical reinforcement to the electrode structure. This helps the electrode withstand the physical stress of repeated charging and discharging cycles, improving battery lifespan and safety.

Enhancing Material Strength and Performance

Carbon nanotubes act as a powerful reinforcing agent when dispersed into other materials, creating advanced composites with superior properties.

Conductive and Reinforced Polymers

When added to polymers, CNTs impart electrical conductivity, transforming insulating plastics into materials that can dissipate static electricity or be used for shielding. Simultaneously, their strength enhances the polymer's durability and toughness.

Stronger Concrete and Asphalt

In construction materials like concrete, CNTs fill microscopic voids and bridge cracks as they form. This nano-reinforcement leads to a significant increase in compressive and tensile strength, resulting in more durable and long-lasting infrastructure.

Advanced Metal and Tire Composites

The principles extend to other materials. In metals, CNTs can improve strength and wear resistance. In tires, they can enhance durability and reduce rolling resistance by improving the properties of the rubber composite.

Understanding the Practical Hurdles

While the potential of CNTs is immense, their practical application is not without challenges. Understanding these trade-offs is critical for successful implementation.

The Dispersion Challenge

By nature, long, thin nanotubes tend to clump together due to strong intermolecular forces. Achieving a uniform dispersion within a host material is the single most critical factor for success and often requires specialized equipment and chemical surface treatments (functionalization).

Production and Cost

While chemical vapor deposition (CVD) has become the dominant commercial production method, the cost and energy intensity of producing high-quality CNTs remain a factor. Emerging methods using waste feedstocks like CO2 are promising but still in development.

The Need for Functionalization

Raw CNTs are often chemically inert. To bond effectively with a host material (like a polymer) or to have specific properties (like solubility), their surfaces must be chemically modified. This process, known as functionalization, adds complexity and cost.

Making the Right Choice for Your Goal

Your perspective on carbon nanotubes will depend entirely on the problem you are trying to solve.

- If your primary focus is energy technology: View CNTs as the key to unlocking higher energy density and faster charging in next-generation batteries.

- If your primary focus is materials science: See CNTs as a multi-functional additive that can simultaneously improve strength, toughness, and electrical conductivity in a wide range of composites.

- If your primary focus is advanced electronics: Consider CNTs a potential pathway to overcoming the limits of silicon for creating ultra-small, high-performance integrated circuits, sensors, and displays.

Ultimately, carbon nanotubes are a tool for pushing the boundaries of what is possible with conventional materials.

Summary Table:

| Application Area | Key Function of CNTs |

|---|---|

| Energy Storage (Batteries) | Conductive additive for higher energy density & longer life |

| Composite Materials | Reinforcement for stronger, tougher, and conductive polymers & concrete |

| Nanoelectronics | Enabling next-generation transistors, sensors, and integrated circuits |

| Conductive Films & Sensors | Creating transparent, flexible, and highly sensitive devices |

Ready to integrate the power of carbon nanotubes into your research or product development?

KINTEK specializes in providing high-quality lab equipment and consumables for advanced material science. Whether you are developing next-generation batteries, stronger composites, or novel electronic devices, we have the tools and expertise to support your work with CNTs.

Contact our experts today via our Contact Form to discuss how our solutions can help you overcome challenges like dispersion and functionalization, accelerating your innovation with carbon nanotubes.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- How do porcelain boats and quartz tubes function in CVD of BN? Optimize Your Boron Nitride Coating Efficiency

- What is a ceramic tube? A Guide to Extreme Environment Performance

- What is the function of a BN inner liner in a graphite mold during Flash Sintering? Master Precise Current Control

- What are 4 disadvantages of brazing? Understanding the Critical Limitations of This Joining Method

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.