Hammer mills are a cornerstone of industrial size reduction, used across a vast range of applications due to their simple design and effectiveness. Their five primary uses include the production of animal feed, the processing of biomass for energy, the milling of grains and spices for food, the large-scale recycling of scrap metal, and the formulation of pharmaceutical powders.

A hammer mill's value comes from its core mechanism: using high-speed, repetitive impact to shatter brittle or fibrous materials. This process allows for precise control over the final particle size, making it a versatile tool for any industry that needs to break down bulk solids into a more manageable form.

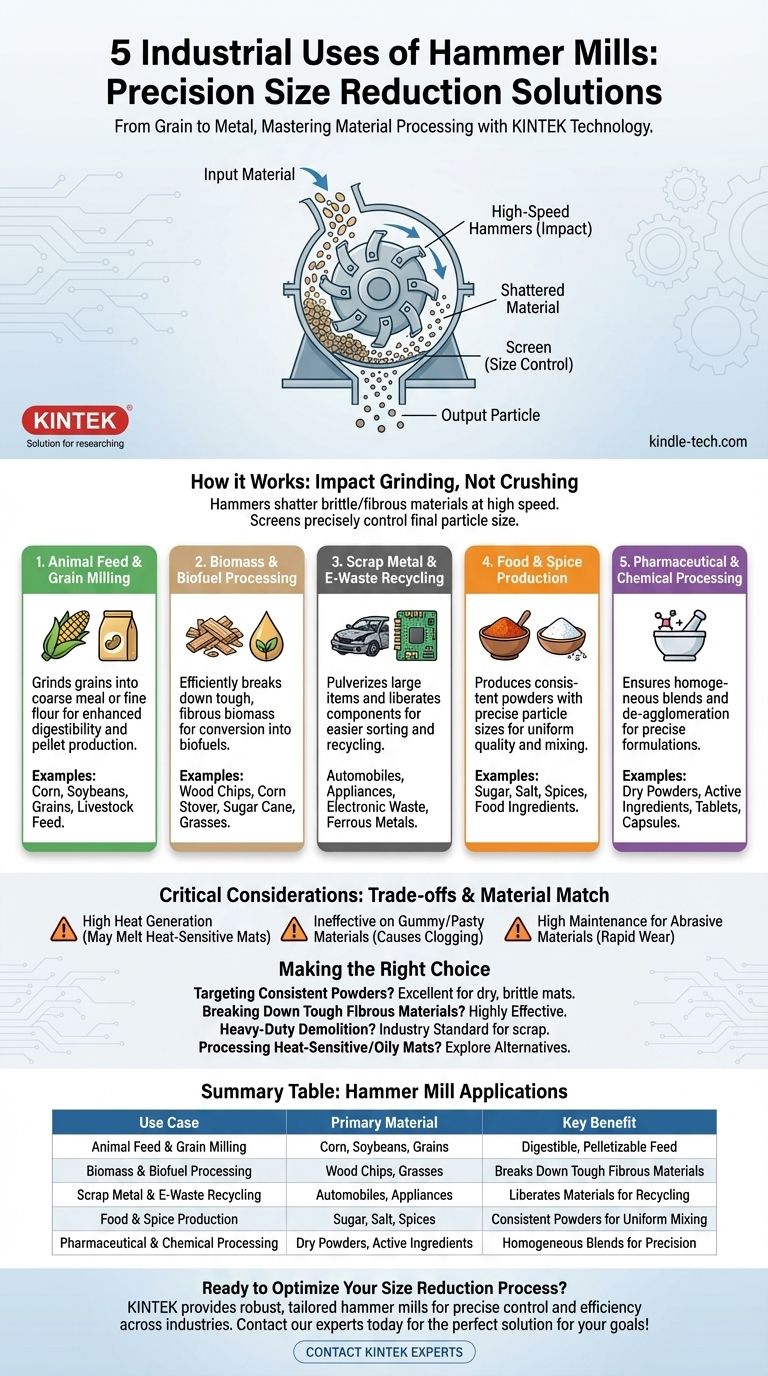

How a Hammer Mill Achieves Size Reduction

A hammer mill operates on a simple but powerful principle of impact grinding. It does not crush or shear material in the way other mills do.

The Core Mechanism

Material is fed into a chamber where multiple hammers are attached to a rotor that spins at very high speed. These hammers strike the material, shattering it upon impact.

The material continues to be struck by the hammers and thrown against the walls of the grinding chamber until it is small enough to pass through a screen or grate that covers the mill's discharge opening. The size of the holes in this screen dictates the maximum size of the finished particle.

Key Industrial Applications

The hammer mill's ability to handle diverse materials makes it invaluable. Its application is determined by the material's properties—specifically, whether it is brittle or fibrous enough to shatter on impact.

1. Animal Feed and Grain Milling

This is one of the most common uses. Hammer mills excel at grinding corn, soybeans, and other grains into a coarse meal or fine flour. This process increases the surface area of the grain, making it more digestible for livestock and serving as the primary step in creating pelletized feed.

2. Biomass and Biofuel Processing

Fibrous materials like wood chips, corn stover, sugar cane, and grasses must be broken down before they can be converted into biofuels like ethanol. The intense, shattering force of a hammer mill is highly effective at reducing the size of these tough, low-density materials.

3. Scrap Metal and E-Waste Recycling

On a much larger and more robust scale, heavy-duty hammer mills—often called shredders—are used to pulverize automobiles, large appliances, and electronic waste. This violent process breaks items into smaller pieces and liberates different materials (e.g., separating plastics and ferrous metals) for easier sorting and recycling.

4. Food and Spice Production

In food processing, hammer mills are used to grind everything from sugar and salt to spices. They are ideal for creating powders with a consistent particle size, which is critical for product quality, dissolving rates, and uniform mixing in recipes.

5. Pharmaceutical and Chemical Processing

Precision is key in pharmaceuticals. Hammer mills are used for de-agglomeration (breaking up clumps), mixing dry powders, and milling active ingredients to a specific particle size distribution. This ensures that the final blend for tablets or capsules is perfectly homogeneous.

Understanding the Trade-offs

While versatile, a hammer mill is not the right tool for every job. Understanding its limitations is critical to avoid process failures.

High Heat Generation

The high-speed impact process generates significant heat. This can be a major problem for heat-sensitive materials like certain plastics, waxy substances, or low-melt-point chemicals, which can melt and coat the inside of the mill.

Ineffective on Gummy or Pasty Materials

Hammer mills are not suitable for very moist, oily, or gummy materials. Instead of shattering, these materials will smear and build up on the hammers and screen, quickly clogging the machine and halting production.

High Maintenance for Abrasive Materials

Processing highly abrasive materials like glass or hard minerals causes rapid wear on the hammers and screens. This results in frequent downtime for maintenance and higher operational costs associated with replacing these consumable parts.

Making the Right Choice for Your Goal

To determine if a hammer mill is appropriate, you must match its strengths to your material and desired outcome.

- If your primary focus is producing consistent powders from dry, brittle materials (like grains, minerals, or dry chemicals): A hammer mill is an excellent choice due to its fine-grinding capability and output control via the screen.

- If your primary focus is breaking down tough, fibrous materials (like wood waste or agricultural biomass): The high-energy shattering action of a hammer mill is one of the most effective methods available.

- If your primary focus is heavy-duty demolition and material liberation (like scrap metal or e-waste): A specialized, robust hammer mill (shredder) is the industry standard for this task.

- If you are processing heat-sensitive, oily, or sticky materials: You should explore alternative size reduction methods, as a hammer mill will likely cause melting, smearing, and operational failure.

By understanding that a hammer mill excels at shattering, not crushing, you can accurately decide if it is the optimal solution for your size reduction needs.

Summary Table:

| Use Case | Primary Material | Key Benefit |

|---|---|---|

| Animal Feed & Grain Milling | Corn, Soybeans, Grains | Creates digestible, pelletizable feed |

| Biomass & Biofuel Processing | Wood Chips, Grasses | Efficiently breaks down tough, fibrous materials |

| Scrap Metal & E-Waste Recycling | Automobiles, Appliances | Liberates materials for easier sorting and recycling |

| Food & Spice Production | Sugar, Salt, Spices | Produces consistent powders for uniform mixing |

| Pharmaceutical & Chemical Processing | Dry Powders, Active Ingredients | Ensures homogeneous blends for precise formulations |

Ready to Optimize Your Size Reduction Process?

KINTEK specializes in providing robust and efficient laboratory equipment, including hammer mills, tailored to your specific industry needs. Whether you're in food production, pharmaceuticals, recycling, or biomass processing, our expertise ensures you get the right solution for precise particle size control and maximum operational efficiency.

Let's discuss your application and find the perfect hammer mill for your goals. Contact our experts today!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.