At its core, a dental furnace is a specialized, high-temperature oven used in a dental laboratory to finalize ceramic restorations like crowns, bridges, and veneers. These furnaces execute precise heating and cooling cycles that transform milled or pressed materials into their final, durable, and esthetically pleasing state.

The crucial function of a dental furnace is not just to heat materials, but to precisely control thermal processes—sintering, firing, and pressing—that are essential for achieving the specific physical properties and esthetics required for different types of dental restorations.

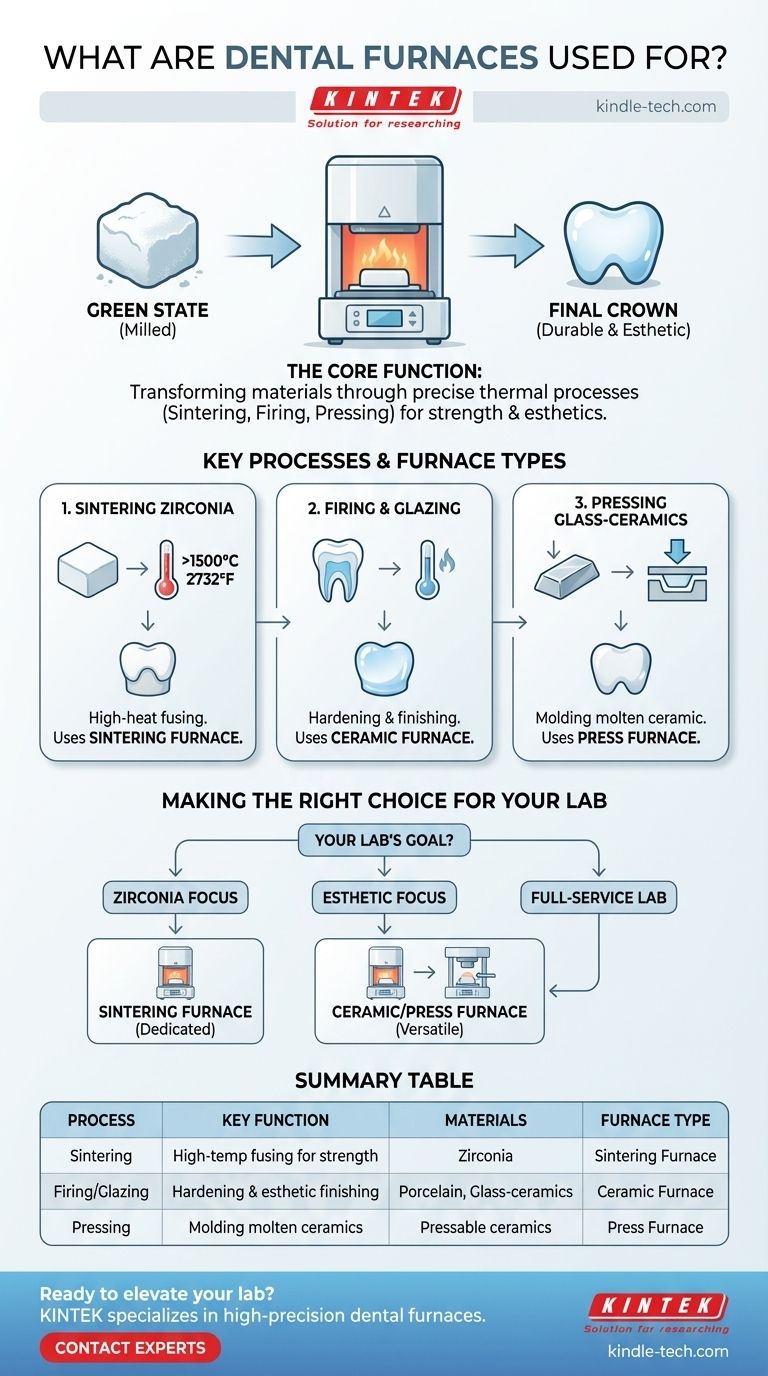

The Core Function: Transforming Materials with Heat

A dental furnace is the final and most critical step in the production of many ceramic restorations. It takes a roughly shaped, fragile piece of material and turns it into a permanent, high-strength prosthetic.

From "Green State" to Final Form

Many modern restorations, especially those made from zirconia, are first milled from a pre-sintered block of material. This softer, chalk-like "green state" is easy to mill but lacks the required strength for clinical use.

The furnace performs the final transformation, hardening the material and shrinking it to its final, dense dimensions.

The Importance of Precision

Modern dental furnaces are microprocessor-controlled, allowing technicians to program and store hundreds of specific firing schedules.

These programs dictate precise rates of heating, holding times at peak temperatures, and controlled cooling. This level of control is not optional; it is essential for preventing cracks, ensuring accurate color, and achieving the designed strength of the material.

Key Processes and Furnace Types

Not all furnaces are the same. The specific process required dictates the type of furnace a laboratory needs. There are three primary functions, each often requiring a different type of furnace.

Sintering Zirconia

Sintering is a process that uses high heat (but not melting) to fuse particles together, drastically increasing the material's density and strength. This is the required process for all zirconia-based restorations.

Sintering furnaces are built specifically for this task, capable of reaching the extremely high temperatures (often over 1500°C / 2732°F) needed to fully sinter zirconia to its final hardness.

Firing and Glazing Ceramics

Traditional porcelain and modern glass-ceramics are built up in layers or stained to achieve natural-looking esthetics. Each layer of porcelain must be "fired" to harden it.

The final step for many restorations is the application of a thin glaze, which is also fired in the furnace to create a smooth, polished, and stain-resistant surface. These processes are performed in a standard ceramic furnace.

Pressing Glass-Ceramics

For "pressable" ceramics, a wax pattern of the restoration is created and encased in an investment material. A ceramic ingot is then heated until it becomes viscous and a plunger in the furnace presses the molten ceramic into the mold.

This requires a combination press furnace, which integrates a pneumatic pressing mechanism with the heating chamber. These furnaces can typically also be used for standard firing and glazing.

Understanding the Trade-offs

A laboratory's choice of furnace is dictated by the materials it plans to work with, as each type has specific capabilities and limitations.

Sintering vs. Ceramic Furnaces: The Temperature Divide

The most significant distinction is temperature capability. A standard ceramic furnace used for firing porcelain cannot reach the ultra-high temperatures required to sinter zirconia.

A lab that produces zirconia restorations must have a dedicated sintering furnace. Attempting to sinter zirconia in a standard ceramic furnace will result in a failed restoration.

The Versatility of Combination Furnaces

Combination press furnaces are highly versatile, allowing a lab to both press and fire/glaze glass-ceramics.

However, these combination furnaces are not designed for sintering zirconia. Therefore, a full-service lab working with both pressable ceramics and zirconia will need at least two different types of furnaces.

Workflow and Specialization

While investing in multiple furnaces requires more capital and space, it allows for a more efficient and specialized workflow. Running a long sintering cycle for zirconia does not tie up the furnace needed for a quick glaze cycle on a different restoration.

Making the Right Choice for Your Goal

Selecting the correct furnace technology is fundamental to a dental lab's success and is determined entirely by its primary services.

- If your primary focus is high-strength zirconia restorations: You require a dedicated sintering furnace capable of executing precise, high-temperature cycles.

- If your primary focus is esthetic glass-ceramics (e.g., e.max): A programmable ceramic furnace is essential, and a combination press furnace is necessary if you intend to offer pressable restorations.

- If you are a full-service lab: You will need both a high-temperature sintering furnace for zirconia and a separate ceramic or combination press furnace to handle all other ceramic materials efficiently.

Understanding the specific thermal process required for each material is the key to producing consistent, high-quality dental restorations.

Summary Table:

| Process | Furnace Type | Key Function | Common Materials |

|---|---|---|---|

| Sintering | Sintering Furnace | High-temperature fusing for strength | Zirconia |

| Firing/Glazing | Ceramic Furnace | Hardening & esthetic finishing | Porcelain, Glass-ceramics |

| Pressing | Press Furnace | Molding molten ceramics | Pressable ceramics (e.g., e.max) |

Ready to elevate your dental lab's capabilities? KINTEK specializes in high-precision dental furnaces for sintering, firing, and pressing—ensuring your crowns, bridges, and veneers meet the highest standards of strength and aesthetics. Contact our experts today to find the perfect furnace for your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What factors determine the maturation of dental porcelain during firing? Master the Time-Temperature Relationship

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- Do ceramic crowns look natural? Achieve a Seamless, Natural-Looking Smile

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- How long does it take to make zirconia teeth? From Same-Day to 2 Weeks

- What does a porcelain furnace do? Create Durable, Aesthetic Dental Restorations

- What is the sintering temperature of zirconia ceramic? Mastering the 1400°C-1600°C Thermal Profile

- What is the firing temperature of dental ceramics? A Guide to Precise Thermal Processing