At its core, a pill press is a mechanical device that compacts powder into a uniform solid tablet. Also known as a tablet press, this machine applies immense force to a measured quantity of granulated or powdered material within a die cavity, forming it into a specific shape, size, and weight. It is the foundational technology behind the production of most tablets consumed worldwide, from medicine to candy.

The essential purpose of a pill press is to transform powders into solid oral dosage forms, ensuring dose accuracy, product stability, and ease of handling. While it is a cornerstone of legitimate industries, its potential for misuse in creating counterfeit goods means it is also a subject of significant regulatory control.

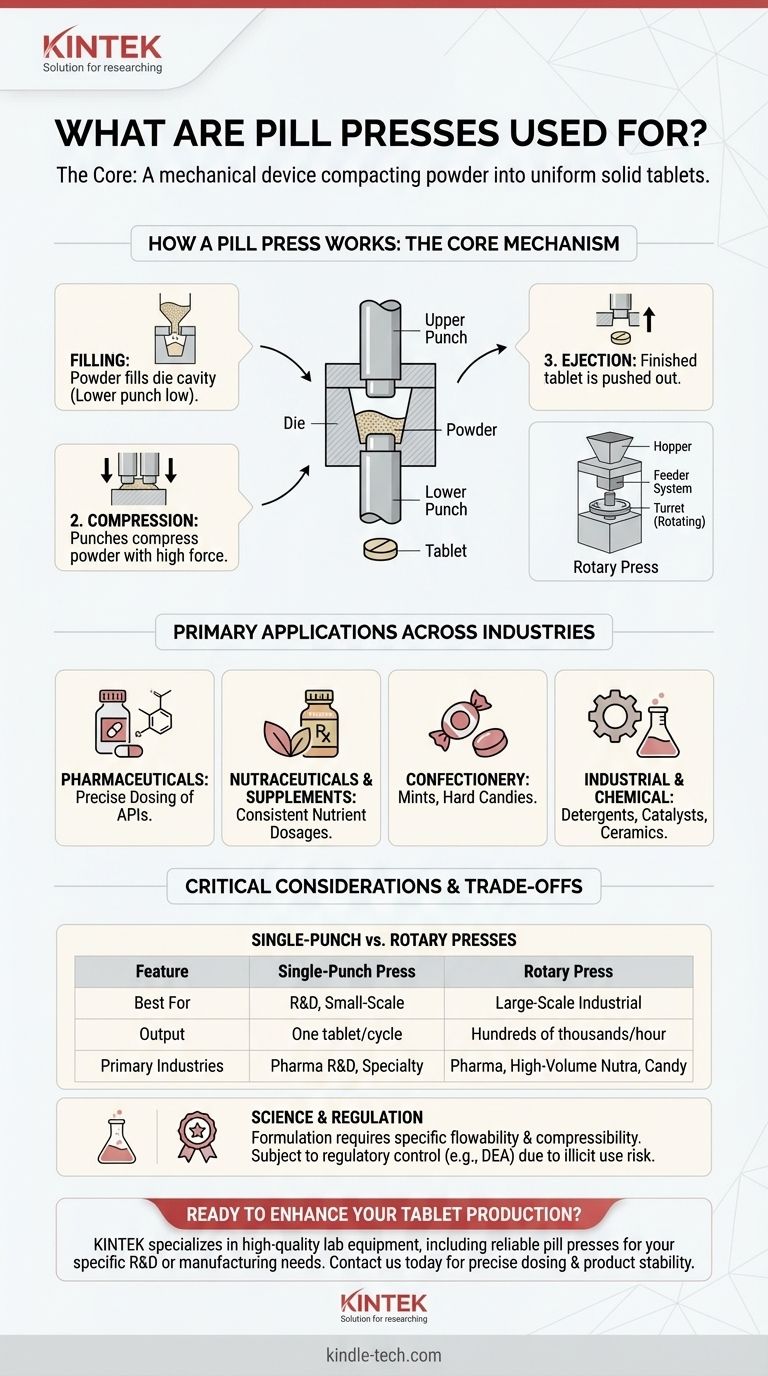

How a Pill Press Works: The Core Mechanism

Understanding a pill press begins with its fundamental mechanical cycle. The process is a sequence of precise, powerful, and repetitive actions designed for mass production.

The Role of Punches and Dies

The heart of any pill press is the tooling, which consists of two punches (an upper and a lower) and a die.

The die is a precision-machined cavity that defines the shape and diameter of the final tablet. The punches are steel rods that move vertically within the die to compress the powder.

The Tablet Compression Cycle

The creation of a single tablet occurs in three distinct steps, repeated rapidly.

- Filling: The lower punch sits low within the die, creating a cavity. A feeder mechanism moves over the die, filling the cavity with a precise volume of powder.

- Compression: The feeder moves away, and the upper punch descends into the die. Both the upper and lower punches are then forced together by high-pressure rollers, compressing the powder with tons of force into a solid tablet.

- Ejection: The upper punch retracts, and the lower punch rises, pushing the finished tablet out of the die, where it is swept away for collection.

Key Components of an Industrial Press

Modern rotary presses include several key systems that work in concert:

- Hopper: Holds the bulk powder formulation before it enters the press.

- Feeder System: A paddle-based or gravity-fed system that transfers the powder from the hopper into the dies consistently.

- Turret: A rotating steel assembly that houses the numerous sets of punches and dies. Its rotation speed determines the machine's output.

Primary Applications Across Industries

While most commonly associated with pharmaceuticals, the utility of tablet compression extends to a surprising number of fields.

Pharmaceuticals

This is the most critical application. Pill presses are essential for manufacturing prescription and over-the-counter medications. They ensure that every tablet contains a precise amount of the Active Pharmaceutical Ingredient (API), guaranteeing accurate dosing.

Nutraceuticals and Supplements

The vitamin, mineral, and herbal supplement industry relies heavily on pill presses. These machines create tablets that offer consistent dosages of nutrients, ensuring product quality and reliability for consumers.

Confectionery

Many familiar candies are made using this technology. Pressed mints, hard dextrose candies, and other sweets are formed using specialized, food-grade tablet presses.

Industrial and Chemical Uses

Tablet presses are also used in various industrial settings. Common examples include producing detergent tablets, catalysts for chemical reactions, industrial salts, and compacted ceramic powders used in manufacturing.

Understanding the Trade-offs and Critical Considerations

A pill press is a precision instrument, and its effective use involves more than just loading powder and turning it on. Several factors are critical to success and safety.

Single-Punch vs. Rotary Presses

There are two main categories of pill presses, distinguished by their output capacity:

- Single-Punch Press: Features one station with a single die and punch set. It produces one tablet per cycle and is used for research and development (R&D) or very small-scale production.

- Rotary Press: The industrial standard. It features a large rotating turret with multiple stations. As the turret spins, each station passes through the filling and compression stages, allowing for outputs of hundreds of thousands of tablets per hour.

The Science of Formulation

Not all powders can be pressed into a stable tablet. The raw powder must possess specific characteristics like good flowability to fill the die evenly and compressibility to form a solid mass. Often, inactive ingredients called excipients (such as binders, lubricants, and fillers) are mixed with the active ingredient to create a functional formulation.

Regulatory Control and Illicit Use

Because pill presses can be used to manufacture counterfeit pharmaceuticals and illegal narcotics with alarming accuracy, they are strictly regulated. Agencies like the U.S. Drug Enforcement Administration (DEA) track the sale and possession of these machines to combat public health risks posed by illicitly produced tablets, which may contain dangerous substances or incorrect dosages.

Making the Right Choice for Your Goal

The appropriate pill press is determined entirely by the scale and purpose of the operation.

- If your primary focus is research and development (R&D): A single-punch press offers the control and small-batch capability needed for testing different powder formulations.

- If your primary focus is small-scale specialty production: An advanced, instrumented single-punch press or a small rotary press provides a good balance between output, cost, and quality control.

- If your primary focus is large-scale industrial manufacturing: A high-speed rotary press is the only viable option to achieve the necessary throughput, efficiency, and cost-effectiveness.

Ultimately, the pill press is a fundamental tool of precision manufacturing, enabling the reliable and scalable production of solid-dose products across a wide range of industries.

Summary Table:

| Feature | Single-Punch Press | Rotary Press |

|---|---|---|

| Best For | R&D, Small-Scale Production | Large-Scale Industrial Manufacturing |

| Output | One tablet per cycle | Hundreds of thousands of tablets per hour |

| Primary Industries | Pharmaceutical R&D, Specialty Supplements | Pharmaceuticals, High-Volume Nutraceuticals, Confectionery |

Ready to enhance your tablet production? Whether you're in R&D or full-scale manufacturing, KINTEK specializes in high-quality lab equipment and consumables, including reliable pill presses tailored to your laboratory's specific needs. Our expertise ensures you get the right equipment for precise dosing, product stability, and efficient handling. Contact us today to discuss your project and discover how KINTEK can support your success in pharmaceuticals, nutraceuticals, and beyond!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- How does a larger area affect the pressure of the same force? Master the Physics of Force Distribution

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing

- What are the disadvantages of press working? High Costs and Design Limits for Mass Production

- What is the use of tablet press? Transforming Powder into Precise, Uniform Tablets

- What are pill presses called? The Correct Term is Tablet Press for Pharmaceutical Manufacturing