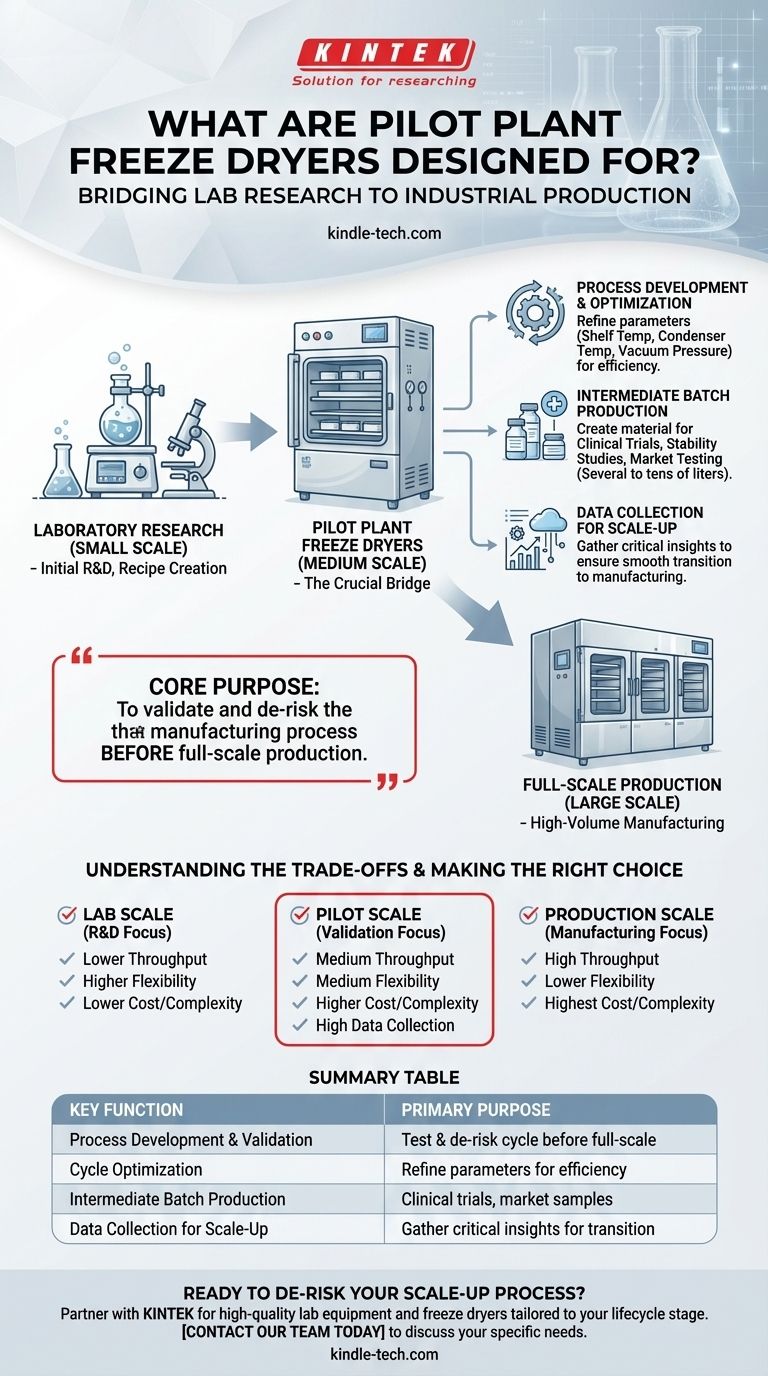

In short, pilot plant freeze dryers are designed to bridge the crucial gap between small-scale laboratory research and full-scale industrial manufacturing. They are used for process development, cycle optimization, and producing medium-sized batches of product for activities like clinical trials or market testing.

The core purpose of a pilot plant freeze dryer is not simply to produce a medium quantity of product, but to validate and de-risk the manufacturing process before committing to the significant expense of full-scale production.

The Fundamental Role of Freeze-Drying

What is Freeze-Drying?

Freeze-drying, or lyophilization, is a dehydration process used to preserve perishable materials. It works by freezing the material and then reducing the surrounding pressure to allow the frozen water to sublimate directly from a solid to a gas.

Why is it Necessary?

This process removes moisture while maintaining the material's structural and chemical integrity. It is essential in the pharmaceutical, biotechnology, and high-end food industries for extending shelf life and ensuring product stability without damaging sensitive compounds like proteins or microorganisms.

Why a "Pilot" Stage is Critical

Bridging the Gap from Lab to Production

A successful recipe on a small benchtop freeze dryer does not guarantee success in a large production unit. A pilot plant model allows scientists and engineers to test how the process behaves with a larger volume, which can significantly alter heat and mass transfer dynamics.

Process Optimization and Validation

This is the primary function of a pilot unit. Teams use it to rigorously test and refine every parameter of the freeze-drying cycle—such as shelf temperature, condenser temperature, and vacuum pressure—to find the most efficient and effective recipe for a larger batch.

Producing Batches for Advanced Testing

Pilot plant freeze dryers can produce quantities ranging from several to tens of liters. This is the ideal scale for creating material needed for clinical trials, stability studies, or producing samples for market evaluation before investing in a full production line.

Understanding the Trade-offs

Throughput vs. Flexibility

A pilot unit offers significantly more throughput than a lab-scale model, but it is not designed for the continuous output of a full-scale production machine. Its value lies in its role as a developmental tool, not a manufacturing workhorse.

Cost and Complexity

These units represent a larger investment in capital, space, and operator training compared to simple benchtop models. However, this investment is minor compared to the cost of discovering a failed process at the full production stage, which could be catastrophic.

Data vs. Simplicity

Pilot freeze dryers are equipped with advanced sensors and control systems to gather the precise data needed for process validation and scale-up. This inherent complexity is a necessary trade-off for the critical insights they provide.

Making the Right Choice for Your Goal

When selecting a freeze dryer, the decision must align with your specific stage in the product lifecycle.

- If your primary focus is initial research and development: A smaller, more flexible benchtop freeze dryer is the most appropriate and cost-effective tool.

- If your primary focus is process validation and preparing for manufacturing: The pilot plant freeze dryer is the essential, non-negotiable step to ensure a smooth transition.

- If your primary focus is high-volume, commercial manufacturing: A dedicated, large-scale production freeze dryer is the only viable solution.

Ultimately, choosing the right equipment is about matching the tool's capability to your immediate strategic objective.

Summary Table:

| Key Function | Primary Purpose |

|---|---|

| Process Development & Validation | Test and de-risk the freeze-drying cycle before full-scale production. |

| Cycle Optimization | Refine parameters like temperature and pressure for efficiency. |

| Intermediate Batch Production | Create material for clinical trials, stability studies, or market samples. |

| Data Collection for Scale-Up | Gather critical insights to ensure a smooth transition to manufacturing. |

Ready to de-risk your scale-up process and ensure a smooth transition to manufacturing?

Choosing the right freeze-drying equipment is critical for success in pharmaceuticals, biotechnology, and food science. At KINTEK, we specialize in providing high-quality lab equipment, including freeze dryers tailored for every stage of your product's lifecycle.

Our experts can help you select the ideal pilot plant freeze dryer to validate your process, optimize cycles, and produce the batches you need for advanced testing. Let us partner with you to bridge the gap from R&D to production efficiently and effectively.

Contact our team today to discuss your specific needs and discover how KINTEK's solutions can accelerate your path to market.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What types of samples are ideal for freeze-drying? Preserve Delicate Biologicals and Materials

- What types of liquid samples can be processed using a laboratory freeze dryer? Preserve Your Sensitive Materials

- How are lab freeze dryers utilized in pharmaceutical research and development? Stabilize Drug Candidates with Lyophilization

- What properties are involved in evaporation? Master the Key Factors for Efficient Drying

- What role do laboratory freeze dryers play in the food industry? Unlock Superior Food Preservation