In short, a laboratory freeze dryer is designed to process a wide range of heat-sensitive liquid samples where structural integrity is paramount. These most commonly include biological materials such as cell cultures, serum, enzymes, antibodies, and vaccines, but its applications extend to chemical and food industries as well.

The core purpose of a freeze dryer isn't simply to remove water, but to do so while preserving the delicate architecture of molecules. By transforming frozen water directly into gas (sublimation), it bypasses the destructive liquid phase, making it the essential tool for stabilizing sensitive substances for long-term storage or transport.

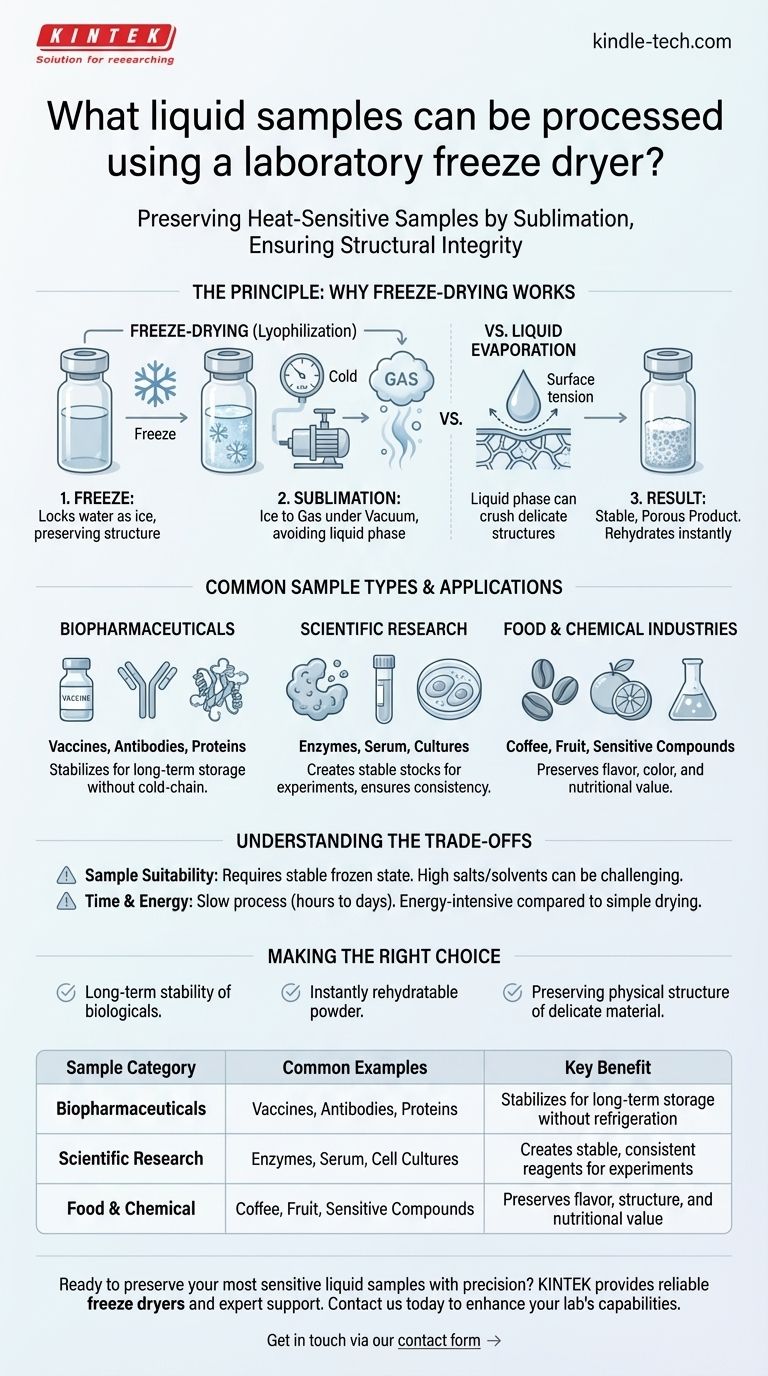

The Principle: Why Freeze-Drying Works

Freeze-drying, or lyophilization, is a dehydration process that works by freezing the material, then reducing the surrounding pressure to allow the frozen water to sublimate directly from a solid to a gas.

From Solid to Gas: The Role of Vacuum and Cold

A freeze dryer's power comes from two key components: a refrigeration system and a vacuum pump. The refrigeration system freezes the sample, locking water molecules in place as ice.

The vacuum pump then drastically lowers the pressure inside the chamber. Under this low pressure, ice no longer needs to melt into a liquid before evaporating; it can transform directly into water vapor.

Preserving Delicate Structures

The true benefit of sublimation is the avoidance of liquid water. Liquid water has high surface tension that can physically crush and denature delicate structures like proteins or cell membranes as it evaporates.

By skipping this liquid phase, freeze-drying prevents the degradation, aggregation, and loss of biological activity that often occurs with heat-based or evaporative drying methods.

The Result: A Stable, Porous Product

The final product is a lightweight, structurally intact, porous solid known as a lyophilizate. This material is highly stable at room temperature and can be stored for years.

Because of its porous nature, it can also be rehydrated almost instantly by adding back the solvent (usually water), restoring the sample to its original state with minimal loss of function.

Common Sample Types and Applications

The ability to preserve integrity makes freeze-drying indispensable across several fields.

Biopharmaceuticals: Vaccines, Antibodies, and Proteins

This is a primary application. Freeze-drying stabilizes vaccines and therapeutic proteins like antibodies, allowing them to be shipped and stored without requiring constant, expensive cold-chain refrigeration.

Scientific Research: Enzymes, Serum, and Cultures

In the lab, researchers freeze-dry enzymes, reference standards, and cell cultures to create stable stocks for experiments. This ensures consistency and extends the usable life of expensive or difficult-to-produce reagents.

Food and Chemical Industries

In the food industry, freeze-drying preserves the flavor, color, and nutritional value of items like coffee, fruit, and astronaut meals. In chemistry, it's used to create stable powders or remove solvents from sensitive compounds.

Understanding the Trade-offs

While powerful, freeze-drying is not a universal solution. It involves specific considerations and limitations.

Sample Suitability is Key

The process relies on the sample being stable in a frozen state. Materials that are damaged by the initial freezing process will not benefit from lyophilization.

Furthermore, samples with high concentrations of salts or certain non-aqueous solvents can be difficult to freeze-dry effectively, as they may not form a stable frozen structure.

It is a Slow and Energy-Intensive Process

Freeze-drying is not fast. A typical cycle can take anywhere from several hours to several days, depending on the sample volume and composition. This makes it far more time-consuming and energy-intensive than simple evaporation or oven drying.

Making the Right Choice for Your Sample

To decide if freeze-drying is right for your goal, consider what you are trying to protect.

- If your primary focus is long-term stability of biologicals: Freeze-drying is the gold standard for preserving the activity of proteins, cells, and vaccines.

- If your primary focus is creating an instantly rehydratable powder: The porous structure of a freeze-dried product is ideal for rapid and complete reconstitution.

- If your primary focus is preserving the physical structure of a delicate material: Sublimation avoids the damaging forces of liquid evaporation, making it the superior choice for fragile samples.

Ultimately, you should choose freeze-drying when your goal is to remove water while leaving the essential character of your sample perfectly intact.

Summary Table:

| Sample Category | Common Examples | Key Benefit |

|---|---|---|

| Biopharmaceuticals | Vaccines, Antibodies, Proteins | Stabilizes for long-term storage without refrigeration |

| Scientific Research | Enzymes, Serum, Cell Cultures | Creates stable, consistent reagents for experiments |

| Food & Chemical | Coffee, Fruit, Sensitive Compounds | Preserves flavor, structure, and nutritional value |

Ready to preserve your most sensitive liquid samples with precision?

KINTEK specializes in providing reliable laboratory freeze dryers and expert support for your unique needs. Whether you are processing vaccines, enzymes, or food products, our equipment ensures the structural integrity and long-term stability of your valuable materials.

Contact us today to discuss how our solutions can enhance your lab's capabilities and protect your critical samples. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis