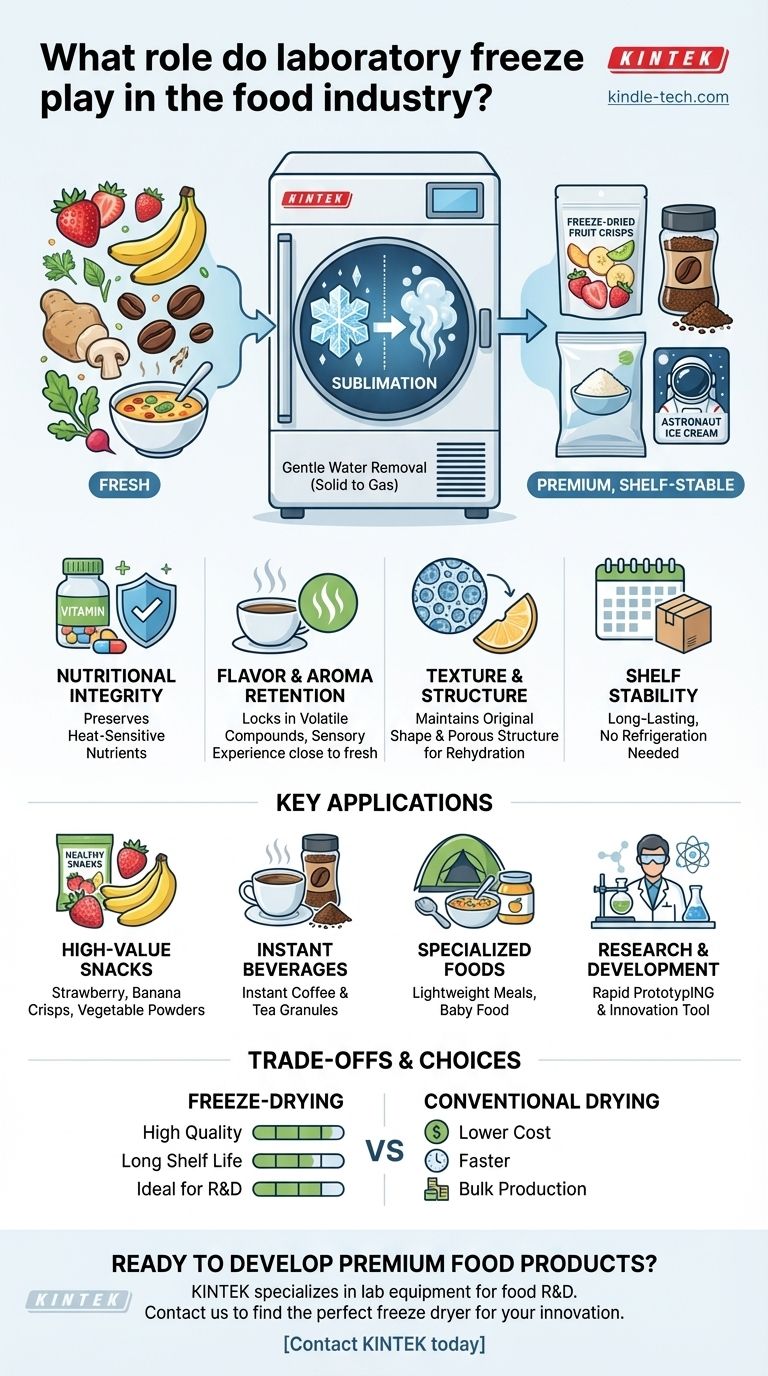

In the food industry, a laboratory freeze dryer serves a critical role in preservation, transforming perishable goods into high-quality, shelf-stable products. This technology removes water through a process called sublimation, which preserves the food's original nutritional value, flavor, color, and texture far better than conventional drying methods. The result is lightweight, long-lasting foods that do not require refrigeration.

While many methods can dehydrate food, freeze-drying is the benchmark technology for preserving the integrity of the final product. It is less about simply removing water and more about locking in the quality that defines a premium food item.

How Freeze-Drying Preserves Ultimate Quality

Unlike conventional dehydration that uses heat, freeze-drying (lyophilization) works by freezing the material and then reducing the surrounding pressure. This allows the frozen water in the food to transition directly from a solid to a gas.

The Principle of Sublimation

The core of freeze-drying is sublimation. By bypassing the liquid phase, the process avoids the significant structural damage caused by heat and water tension.

This gentle removal of water leaves the food's cellular structure, flavor compounds, and nutritional profile almost entirely intact.

Preserving Nutritional Integrity

Heat can degrade vitamins and other sensitive nutrients. Because freeze-drying is a low-temperature process, it is exceptionally effective at retaining the nutritional value of the original raw material.

This makes it the preferred method for producing health-focused foods, supplements, and nutraceutical ingredients where potency is paramount.

Retaining Flavor and Aroma

The volatile compounds responsible for flavor and aroma are easily lost during heat-based drying. Freeze-drying locks these compounds in place.

This is why freeze-dried coffee granules, herbs, and spices offer a sensory experience much closer to their fresh counterparts.

Maintaining Original Structure and Texture

Freeze-drying creates a porous structure that allows the product to rehydrate almost instantly. The food maintains its original shape, size, and a surprisingly crisp or light texture.

This is evident in products like freeze-dried fruits, which remain whole and crunchy, or astronaut ice cream, which retains its original form.

Key Applications in the Food Industry

The unique benefits of freeze-drying support a wide range of applications, from consumer-facing products to critical research and development.

High-Value Snacks and Ingredients

Freeze-drying is the go-to method for creating premium, healthy snacks. Popular examples include whole strawberries, sliced bananas, and vegetable crisps.

It is also used to produce powdered ingredients like fruit or vegetable powders that deliver concentrated flavor and color to other food products.

Instant Beverages

The modern instant coffee industry was built on freeze-drying. The process creates granules that dissolve quickly while preserving the rich flavor and aroma of the original brew.

The same technology is applied to create high-quality instant teas and other powdered beverage mixes.

Specialized and Convenience Foods

Freeze-drying enables the creation of lightweight, nutrient-dense meals for campers, hikers, and military personnel. It is also ideal for producing long-lasting baby food that rehydrates quickly and safely.

Research and Product Development

In a laboratory setting, freeze dryers are indispensable tools for food scientists. They allow for rapid prototyping and experimentation with new food concepts, ingredients, and preservation techniques on a small, controlled scale.

Understanding the Trade-offs

While freeze-drying offers superior results, it is a specialized process with distinct operational considerations that make it unsuitable for every application.

High Initial Investment and Operating Costs

Freeze-drying equipment is more complex and expensive than conventional dehydrators. The process is also energy-intensive due to the deep vacuum and refrigeration required, leading to higher operating costs.

Longer Processing Times

A typical freeze-drying cycle can take 24 hours or longer, depending on the product and equipment. This is significantly slower than heat-based drying methods, which can take just a few hours.

Suitability for High-Moisture Products

The technology is most effective and efficient for products with high water content. It may not be the most economical choice for foods with lower initial moisture levels, where other methods could suffice.

Making the Right Choice for Your Goal

Selecting a drying method depends entirely on your project's priorities, balancing cost, speed, and desired end-product quality.

- If your primary focus is premium quality and long-term shelf life: Freeze-drying is the undisputed best choice for preserving nutritional value, flavor, and texture.

- If your primary focus is rapid, low-cost bulk production: Conventional air or oven drying is a more economical and faster alternative, though it comes at the cost of product quality.

- If your primary focus is new product development and innovation: A laboratory freeze dryer is an essential R&D tool for creating high-value, novel food products.

Ultimately, adopting freeze-drying is an investment in delivering a superior product that stands apart in the marketplace.

Summary Table:

| Key Advantage | Description |

|---|---|

| Nutritional Integrity | Preserves heat-sensitive vitamins and nutrients better than heat-based drying. |

| Flavor & Aroma Retention | Locks in volatile compounds, offering a sensory experience close to fresh food. |

| Texture & Structure | Creates a porous structure for instant rehydration and maintains original shape. |

| Shelf Stability | Produces lightweight, long-lasting food that does not require refrigeration. |

Ready to develop premium, shelf-stable food products with unparalleled quality?

KINTEK specializes in lab equipment and consumables, serving the precise needs of food laboratories. Our freeze dryers are the essential R&D tool for food scientists focused on innovation, helping you create high-value snacks, ingredients, and instant beverages while preserving critical nutritional and sensory properties.

Invest in the benchmark technology for food preservation. Contact KINTEK today to find the perfect laboratory freeze dryer for your project!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure