At its core, a muffle furnace is an oven designed for high-purity, high-temperature applications. Its primary advantage is an inner chamber—the "muffle"—that isolates the material being heated from contaminants and direct radiation from the heating elements. This provides exceptional temperature uniformity and process control, but it also means heating cycles are slower and access to the interior is more constrained compared to direct-heating methods.

A muffle furnace trades speed for precision. It is the definitive tool when sample purity and perfectly uniform heating are non-negotiable, but it is less ideal for applications where rapid heating is the top priority.

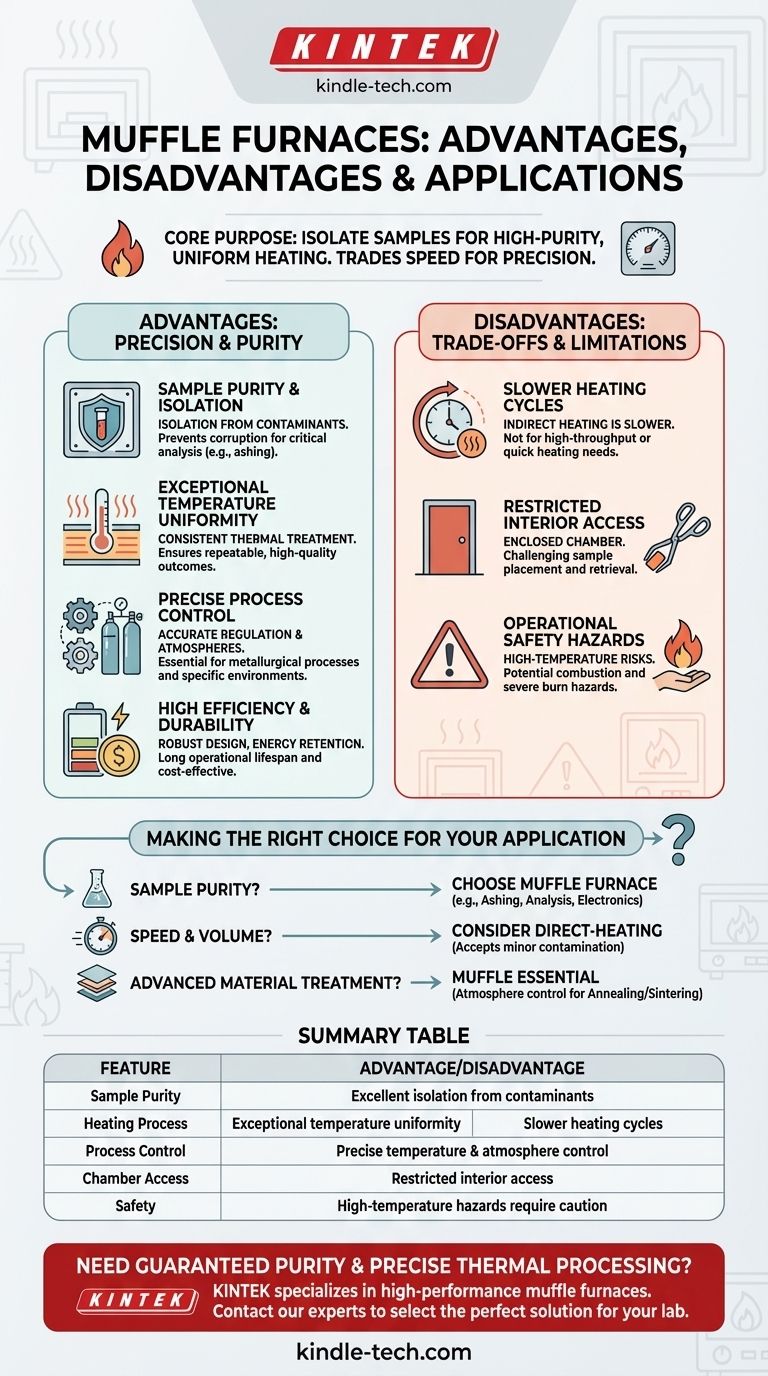

The Core Advantages: Precision and Purity

A muffle furnace's design directly enables its key benefits. The separation between the heating elements and the processing chamber is the source of its unique capabilities.

Sample Purity and Isolation

The defining feature of a muffle furnace is its ability to protect the sample. The muffle chamber acts as a physical barrier, preventing contamination from fuel byproducts, combustion gases, or flaking from the heating elements themselves.

This isolation is critical for chemical analysis, such as ashing, where any external material would corrupt the results.

Exceptional Temperature Uniformity

Because the sample is not exposed to direct radiant heat, the furnace heats the entire chamber evenly. This creates a highly uniform temperature environment from top to bottom.

This uniformity ensures that an entire batch of material or a single large component receives the exact same thermal treatment, leading to consistent and repeatable outcomes.

Precise Process Control

Modern muffle furnaces offer very accurate temperature regulation. The design also allows for controlled atmospheres, meaning the chamber can be filled with inert gases like nitrogen or reactive gases like hydrogen.

This capability is essential for specific metallurgical processes or scientific experiments that require a non-oxidizing or specific chemical environment.

High Efficiency and Durability

These furnaces are built with high-quality insulation and heat-resistant materials. This not only improves energy efficiency by retaining heat but also contributes to a robust design and a long operational lifespan.

Their construction is meant to withstand constant high-temperature cycles, making them a reliable and cost-effective investment over time.

Understanding the Trade-offs and Limitations

The precision of a muffle furnace comes with practical drawbacks that are crucial to understand before selecting one for your process.

Slower Heating Cycles

The indirect heating method is inherently slower. The furnace must first heat the muffle chamber, which then radiates heat to the sample.

This "warm-up" time makes muffle furnaces less suitable for high-throughput applications or any project that requires very quick heating cycles.

Restricted Interior Access

The enclosed chamber design, necessary for uniformity and isolation, makes placing and retrieving samples more challenging than in an open-hearth or belt furnace.

Materials must be carefully positioned with tongs or other tools, which can be cumbersome, especially with large or awkwardly shaped items.

Operational Safety Hazards

High temperatures present inherent risks. Materials, especially volatile pellets or powders, can combust or even explode upon contact with the pre-heated chamber interior.

Operators must exercise caution, as reaching into the furnace can cause severe burns. Furthermore, heated particles can sometimes escape the muffle, posing a risk to the surrounding area and equipment.

Making the Right Choice for Your Application

Selecting the right furnace requires aligning the tool's strengths and weaknesses with your primary goal.

- If your primary focus is sample purity and repeatable results: The muffle furnace is the superior choice for applications like ashing, chemical analysis, and delicate electronics testing.

- If your primary focus is speed and high-volume processing: A direct-heating furnace may be more efficient, assuming minor sample contamination from the heating elements is acceptable.

- If your primary focus is advanced material treatment: The ability to control the atmosphere with specific gases makes the muffle furnace essential for processes like annealing or sintering metals without oxidation.

Ultimately, choosing a muffle furnace is a deliberate decision to prioritize the integrity and uniformity of your thermal process.

Summary Table:

| Feature | Advantage | Disadvantage |

|---|---|---|

| Sample Purity | Excellent isolation from contaminants | - |

| Heating Process | Exceptional temperature uniformity | Slower heating cycles |

| Process Control | Precise temperature & atmosphere control | - |

| Chamber Access | - | Restricted interior access |

| Safety | - | High-temperature hazards require caution |

Need a furnace that guarantees sample purity and precise thermal processing? KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for applications where contamination-free, uniform heating is critical. Our experts can help you select the perfect furnace for your laboratory's specific needs in chemical analysis, materials testing, and more. Contact KINTEL today to discuss your requirements and enhance your lab's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the five common heat treatments of metals? Master the Processes for Precise Material Properties

- What is the yield of biochar in slow pyrolysis? Maximize Your Output Up to 30%

- What is the working principle of muffle furnace? Achieving Pure, Uniform High-Temperature Processing

- What is the heat transfer of a muffle furnace? Understanding Indirect Heating for Purity

- What is the importance of muffle furnace? Ensuring Contaminant-Free Heating for Accurate Results