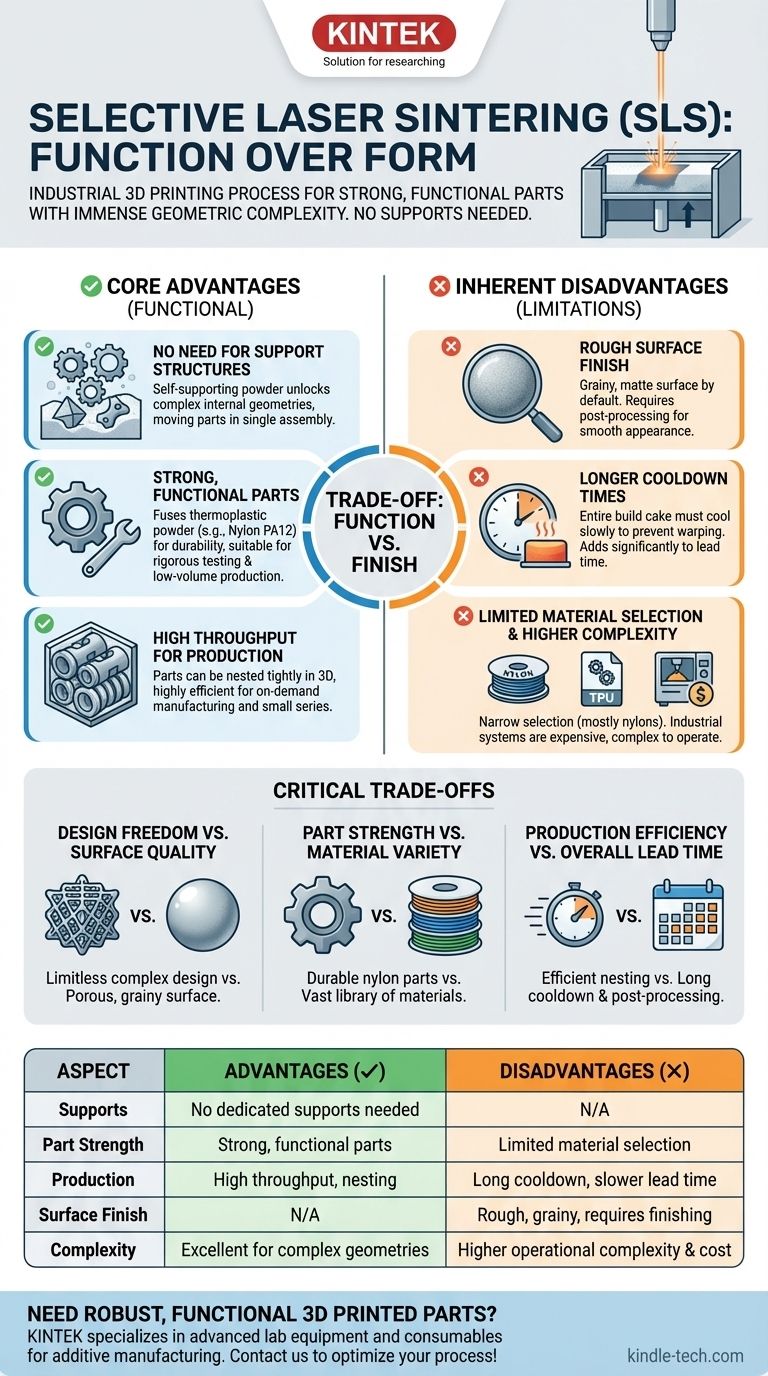

At its core, Selective Laser Sintering (SLS) is an industrial 3D printing process prized for producing strong, functional parts with immense geometric complexity. Its primary advantage is that it requires no dedicated support structures, as the unused powder in the build chamber supports the part during printing. However, this strength and design freedom comes at the cost of a rough, porous surface finish and more limited material options compared to other methods.

The central trade-off of SLS is simple: you gain unparalleled design freedom and robust mechanical properties in exchange for a lower-resolution surface finish and longer processing times. It is a technology built for function over form.

The Core Advantages of SLS Explained

SLS technology excels in applications where the mechanical performance and geometric complexity of a part are more critical than its surface aesthetics.

No Need for Support Structures

The most significant advantage of SLS is its self-supporting nature. The unsintered powder that surrounds the part during the build process acts as a natural, granular support.

This single feature unlocks the ability to create incredibly complex internal geometries, interlocking components, and moving parts printed in a single assembly—feats that are difficult or impossible with technologies like FDM or SLA that require disposable supports.

Strong, Functional Parts

SLS printers fuse thermoplastic powder (most commonly Nylon PA12) into a solid object, creating parts with good mechanical properties like strength and durability.

The resulting components are suitable for rigorous functional testing, manufacturing aids like jigs and fixtures, and even low-volume production of end-use parts.

High Throughput for Production

Because no support structures are needed, parts can be "nested" or packed tightly together in three dimensions throughout the entire build volume.

This allows for the simultaneous production of many different parts in a single print run, making SLS highly efficient and cost-effective for on-demand manufacturing and small production series.

Understanding the Inherent Disadvantages

The same process that gives SLS its strengths also creates its primary limitations. Understanding these is key to deciding if it's the right technology for your project.

Rough Surface Finish

The final parts have a grainy, matte surface finish by default. This is a direct result of the powder-based fusion process.

While post-processing techniques like media tumbling or vapor smoothing can improve the finish, a raw SLS part is not suitable for applications requiring optical clarity or a smooth, injection-molded appearance out of the printer.

Longer Cooldown Times

The entire block of fused and unfused powder, known as the "build cake," must cool down slowly and controllably inside the printer. This can take many hours.

Rushing this cooldown period can lead to part warping and dimensional inaccuracy. This necessary delay adds significantly to the total lead time from print start to part-in-hand.

Limited Material Selection

While the materials available for SLS are robust, the selection is narrow compared to other methods. The market is dominated by nylons (PA11, PA12), with some flexible TPU and filled composite options available.

You will not find the wide range of colors, transparencies, or specialized resins available with technologies like Fused Deposition Modeling (FDM) or Stereolithography (SLA).

Higher Operational Complexity

SLS systems are industrial-grade machines that are more expensive and complex to operate than desktop printers. They require dedicated space, significant power, and careful management of the powder material to ensure safety and part quality.

The Critical Trade-offs: Function vs. Finish

Choosing SLS means actively prioritizing certain capabilities over others. The decision almost always hinges on the following trade-offs.

Design Freedom vs. Surface Quality

This is the primary trade-off. SLS offers nearly limitless design freedom for complex internal channels and consolidated assemblies, but the price is a porous and grainy surface. If your part must be visually perfect without post-processing, SLS is the wrong choice.

Part Strength vs. Material Variety

You get strong, durable, engineering-grade nylon parts that can withstand mechanical stress. However, you sacrifice access to the vast and affordable library of filaments (like PLA, PETG, ABS) used in FDM or the specialized photopolymer resins of SLA.

Production Efficiency vs. Overall Lead Time

Nesting parts makes the printing phase itself highly efficient for small series production. However, the lengthy cooldown and necessary post-processing steps (like de-powdering and cleaning) mean the total turnaround time can be longer than with other technologies.

Making the Right Choice for Your Goal

To determine if SLS is the correct technology, evaluate your project's most critical requirement.

- If your primary focus is complex geometries and functional prototyping: SLS is likely the best choice due to its strength and support-free printing process.

- If your primary focus is low-volume production of durable end-use parts: The part-nesting capability and robust material properties make SLS a highly efficient solution.

- If your primary focus is smooth, high-detail visual models: You should use a resin-based technology like SLA or PolyJet to achieve the required surface quality.

- If your primary focus is low cost and exploring a wide variety of materials: FDM remains the most accessible and versatile option for less demanding applications.

By understanding these core trade-offs, you can confidently select SLS for applications that play to its unique strengths in functional complexity.

Summary Table:

| Aspect | Advantages of SLS | Disadvantages of SLS |

|---|---|---|

| Supports | No dedicated supports needed; self-supporting powder | N/A |

| Part Strength | Strong, functional parts; good for testing & end-use | Limited material selection (mostly nylons) |

| Production | High throughput; parts can be nested for efficiency | Long cooldown times; slower overall lead time |

| Surface Finish | N/A | Rough, grainy surface; requires post-processing |

| Complexity | Excellent for complex geometries and moving assemblies | Higher operational complexity and cost |

Need robust, functional 3D printed parts for your lab or production line? KINTEK specializes in providing advanced lab equipment and consumables, including solutions for additive manufacturing. Whether you're prototyping complex components or producing durable end-use parts, our expertise can help you optimize your process. Contact us today to discuss how SLS technology can meet your specific laboratory and manufacturing needs!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- How should a sample be installed onto the sample holder? Ensure Mechanical Stability & Electrical Integrity

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- How does a laboratory hydraulic press contribute to MIC testing? Ensure Precision in Stainless Steel Specimens

- What are the advantages of an electrolytic polishing device for EK-181 steel TEM samples? Ensure Peak Sample Integrity

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration