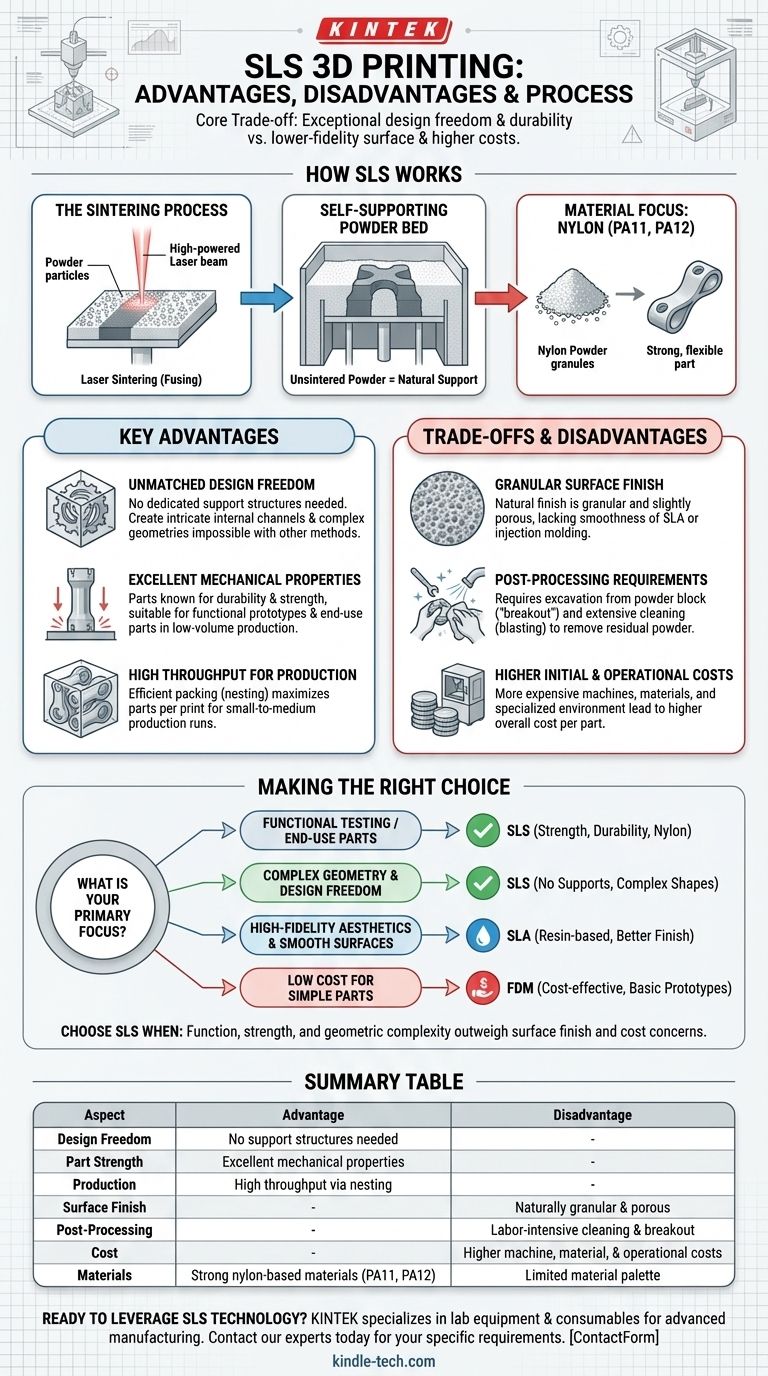

In short, Selective Laser Sintering (SLS) is a 3D printing process prized for its ability to produce strong, functional parts with immense geometric freedom. Its primary advantages are its excellent mechanical properties and the elimination of dedicated support structures, while its main disadvantages are a rough surface finish, higher costs, and more involved post-processing.

The core trade-off with SLS is clear: you gain exceptional design freedom and part durability in exchange for a lower-fidelity surface finish and higher operational costs compared to other polymer printing methods.

How the SLS Process Defines Its Outcomes

To understand the advantages and disadvantages, you must first understand the core mechanics. SLS is a powder bed fusion technology that builds parts layer by layer without the need for traditional supports.

The Sintering Process

An SLS printer spreads a thin layer of polymer powder (most commonly nylon) over a build platform. A high-powered laser then selectively scans the layer, sintering—or fusing—the powder particles together to form a solid cross-section of the object.

The Self-Supporting Powder Bed

After a layer is complete, the platform lowers, and a new layer of powder is spread on top. The key is that the unsintered powder in the build chamber remains in place, acting as a natural, built-in support system for the part being printed.

Material Focus: Nylon and its Variants

The most common material for SLS is Nylon (PA11, PA12) and its composites (e.g., glass-filled or carbon-filled nylon). These materials are known for their strength, flexibility, and resistance to impact and chemicals, making them suitable for real-world applications.

Key Advantages of SLS

The unique, self-supporting nature of the SLS process gives it distinct advantages, particularly for engineering applications.

Unmatched Design Freedom

Because the loose powder supports the part during printing, dedicated support structures are not required. This is the single greatest advantage of SLS, allowing for the creation of intricate internal channels, interlocking components, and other complex geometries that are difficult or impossible with other methods like FDM or SLA.

Excellent Mechanical Properties

SLS parts are known for their durability and strength, closely resembling injection-molded plastics. This makes the technology ideal for creating functional prototypes that can withstand rigorous testing and for end-use parts in low-volume production.

High Throughput for Production

An entire build volume can be packed with multiple parts, a process known as nesting. Since parts don't need dedicated supports, they can be arranged তিন-dimensionally to maximize the number of components in a single print job, making it highly efficient for small-to-medium production runs.

Understanding the Trade-offs and Disadvantages

No technology is perfect. The inherent nature of sintering powder creates specific limitations you must consider.

The Granular Surface Finish

Because parts are formed from fused powder, their natural surface finish is granular and slightly porous. It lacks the smoothness of parts made with SLA (stereolithography) or injection molding. While this can be improved with post-processing, it is an inherent characteristic of the process.

Post-Processing Requirements

The printing process is only the first step. Parts must be excavated from the block of unsintered powder, a process called a "breakout." They then require extensive cleaning, typically with compressed air or bead blasting, to remove all residual powder. This adds labor and time to the workflow.

Higher Initial and Operational Costs

SLS machines are significantly more expensive than common FDM or desktop SLA printers. The materials are also more costly, and the process requires a controlled environment and specialized powder-handling equipment, leading to a higher overall cost per part, especially for one-off prints.

Limited Material Palette

While materials like TPU offer flexibility, the SLS ecosystem is dominated by nylon and its derivatives. The material selection is far more limited compared to the vast range of filaments available for FDM printing.

Making the Right Choice for Your Project

Your application's specific requirements will determine if SLS is the right choice. Use these guidelines to make an informed decision.

- If your primary focus is functional testing or end-use parts: SLS is an excellent choice due to the superior mechanical strength and durability of its nylon-based materials.

- If your primary focus is complex geometry and design freedom: The self-supporting nature of SLS makes it the clear winner for parts with internal channels or interlocking features.

- If your primary focus is high-fidelity aesthetics and smooth surfaces: SLA or a similar resin-based technology will deliver a much better result with less post-processing effort.

- If your primary focus is low cost for simple parts: FDM printing remains the most cost-effective solution for basic prototypes and components where mechanical performance is less critical.

Choose SLS when the function, strength, and geometric complexity of your part outweigh the need for a perfect surface finish and a low initial cost.

Summary Table:

| Aspect | Advantage | Disadvantage |

|---|---|---|

| Design Freedom | No support structures needed for complex geometries | - |

| Part Strength | Excellent mechanical properties, durable for end-use | - |

| Production | High throughput via nesting in build volume | - |

| Surface Finish | - | Naturally granular and porous |

| Post-Processing | - | Labor-intensive cleaning and breakout required |

| Cost | - | Higher machine, material, and operational costs |

| Materials | Strong nylon-based materials (PA11, PA12) | Limited material palette compared to other methods |

Ready to leverage SLS technology for your lab's prototyping or production needs?

KINTEK specializes in providing the lab equipment and consumables that power advanced manufacturing processes like Selective Laser Sintering. Whether you are creating functional prototypes or end-use parts, our expertise ensures you have the right tools for success.

Contact our experts today to discuss how we can support your laboratory's specific SLS and 3D printing requirements with reliable equipment and materials.

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Small Injection Molding Machine for Lab Use

- Powerful Plastic Crusher Machine

People Also Ask

- What is the process of double extrusion? Create Integrated Multi-Material Components

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What are the disadvantages of the extrusion process? High Costs and Geometric Limits Explained

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What are the advantages of blown film extrusion? Boost Your Film Production Efficiency