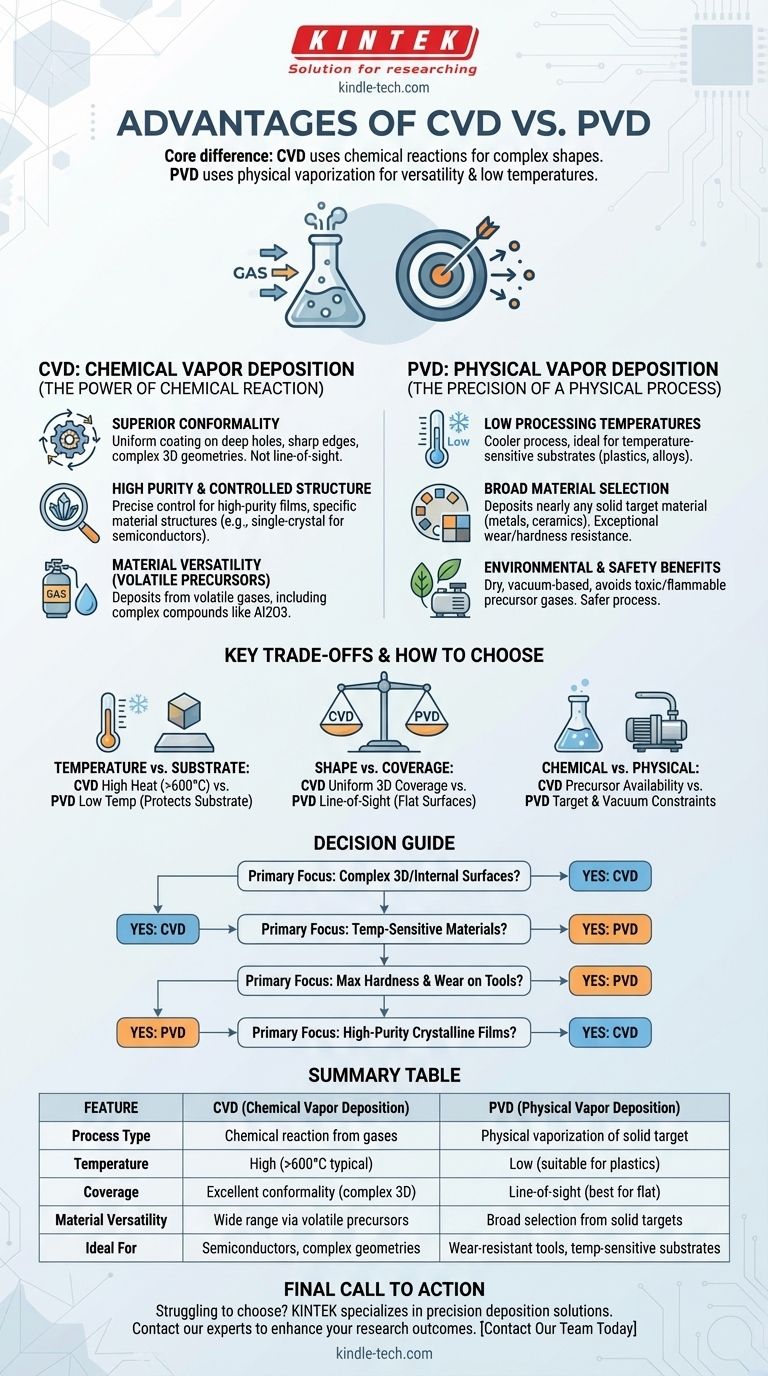

At their core, the advantages of Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) stem from their fundamentally different processes. CVD uses a chemical reaction of precursor gases to grow a film, giving it superior ability to uniformly coat complex shapes. PVD uses a physical process of bombarding and vaporizing a solid source material, allowing it to operate at much lower temperatures and deposit a wider range of materials.

The choice between CVD and PVD is a strategic engineering decision. It forces a trade-off between CVD’s exceptional ability to coat intricate geometries and PVD’s versatility and low-temperature application, which protects sensitive substrates.

Understanding CVD: The Power of Chemical Reaction

Chemical Vapor Deposition is not merely applying a coating; it is growing a new material directly on the substrate's surface through a controlled chemical reaction. This unique mechanism is the source of its primary advantages.

Superior Conformality

Because CVD relies on precursor gases that surround the part, it is not a "line-of-sight" process. The chemical reaction occurs on all exposed surfaces simultaneously.

This allows CVD to deposit films of uniform thickness inside deep holes, on sharp edges, and over highly complex 3D geometries where PVD would fail.

High Purity and Controlled Structure

The inputs to a CVD process are high-purity gases. By precisely controlling parameters like gas flow, pressure, and temperature, you can achieve exceptionally high-purity films.

This control also allows for the synthesis of specific material structures, from single-crystal to polycrystalline or amorphous films, which is critical for applications like semiconductors.

Material Versatility from Volatile Precursors

CVD can deposit materials that are otherwise very difficult to evaporate, a requirement for PVD. If an element can be synthesized into a volatile chemical compound (a precursor gas), it can likely be deposited via CVD.

This opens the door to complex materials and compounds, including the deposition of high-quality aluminum oxide (Al2O3), which is challenging for many PVD processes.

Understanding PVD: The Precision of a Physical Process

Physical Vapor Deposition works by physically blasting atoms from a solid target in a vacuum and having them condense onto the substrate. This direct, physical transfer gives it a different set of powerful advantages.

Low Processing Temperatures

This is arguably PVD’s most significant advantage. Because it does not rely on high-temperature chemical reactions, PVD processes run much cooler than typical CVD processes.

This makes PVD the only viable choice for coating temperature-sensitive substrates like plastics, certain aluminum alloys, and other materials that would be damaged or warped by the heat of CVD.

Broad Material Selection

PVD can deposit nearly any material that can be made into a solid target, including metals, alloys, and ceramics. The process is less dependent on complex chemical availability than CVD.

Modern PVD technology is constantly expanding its material library, offering exceptional wear resistance, hardness, and impact resistance that now rivals or exceeds CVD in many tooling and component applications.

Environmental and Safety Benefits

PVD is a dry, vacuum-based process. It generally avoids the use of the toxic, flammable, or corrosive precursor gases and hazardous byproducts that are often a necessary part of CVD. This makes the process inherently safer and more environmentally friendly.

Key Trade-offs: Temperature vs. Conformality

Neither method is universally superior. Your choice depends entirely on navigating the inherent trade-offs between the two technologies.

The Temperature vs. Substrate Dilemma

The high temperatures of CVD (often >600°C) can promote excellent coating adhesion and density. However, this same heat can damage the substrate, alter its properties, or induce thermal stress. PVD’s low temperature protects the substrate but may require more surface preparation to ensure strong adhesion.

The Shape vs. Coverage Dilemma

CVD's ability to coat uniformly is its defining strength for complex parts. For a simple, flat surface, this advantage is irrelevant. PVD’s line-of-sight nature means it is perfect for flat surfaces but will create thin or non-existent coatings in shadowed areas or deep recesses.

The Chemical vs. Physical Constraints

CVD is limited by the availability of suitable, high-purity precursor gases, which can be expensive and difficult to handle. PVD is limited by the need to create a solid target and operate in a high vacuum, but the range of potential source materials is vast.

How to Choose Between CVD and PVD

Your final decision must be guided by the non-negotiable requirements of your project.

- If your primary focus is coating complex 3D shapes or internal surfaces: CVD is the superior choice due to its non-line-of-sight deposition that ensures uniform coverage.

- If your primary focus is coating temperature-sensitive materials like polymers or certain alloys: PVD is the necessary choice because of its significantly lower process temperatures.

- If your primary focus is achieving maximum hardness and wear resistance on tools: PVD is the modern industry standard, offering a wide and growing range of high-performance hard coatings.

- If your primary focus is creating high-purity, dense, crystalline films for electronics: CVD provides the exceptional process control required for semiconductor and optical applications.

Choosing the right deposition method is about aligning the fundamental capabilities of the process with the specific engineering goals for your component.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

|---|---|---|

| Process Type | Chemical reaction from gases | Physical vaporization of solid target |

| Temperature | High (>600°C typical) | Low (suitable for plastics) |

| Coverage | Excellent conformality on complex 3D shapes | Line-of-sight (best for flat surfaces) |

| Material Versatility | Wide range via volatile precursors | Broad selection from solid targets |

| Ideal For | Semiconductors, complex geometries | Wear-resistant tools, temperature-sensitive substrates |

Struggling to choose between CVD and PVD for your lab's coating needs? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision deposition solutions. Our experts can help you select the ideal system based on your substrate material, geometry, and performance requirements. Contact our team today to discuss how our CVD and PVD technologies can enhance your research and development outcomes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method