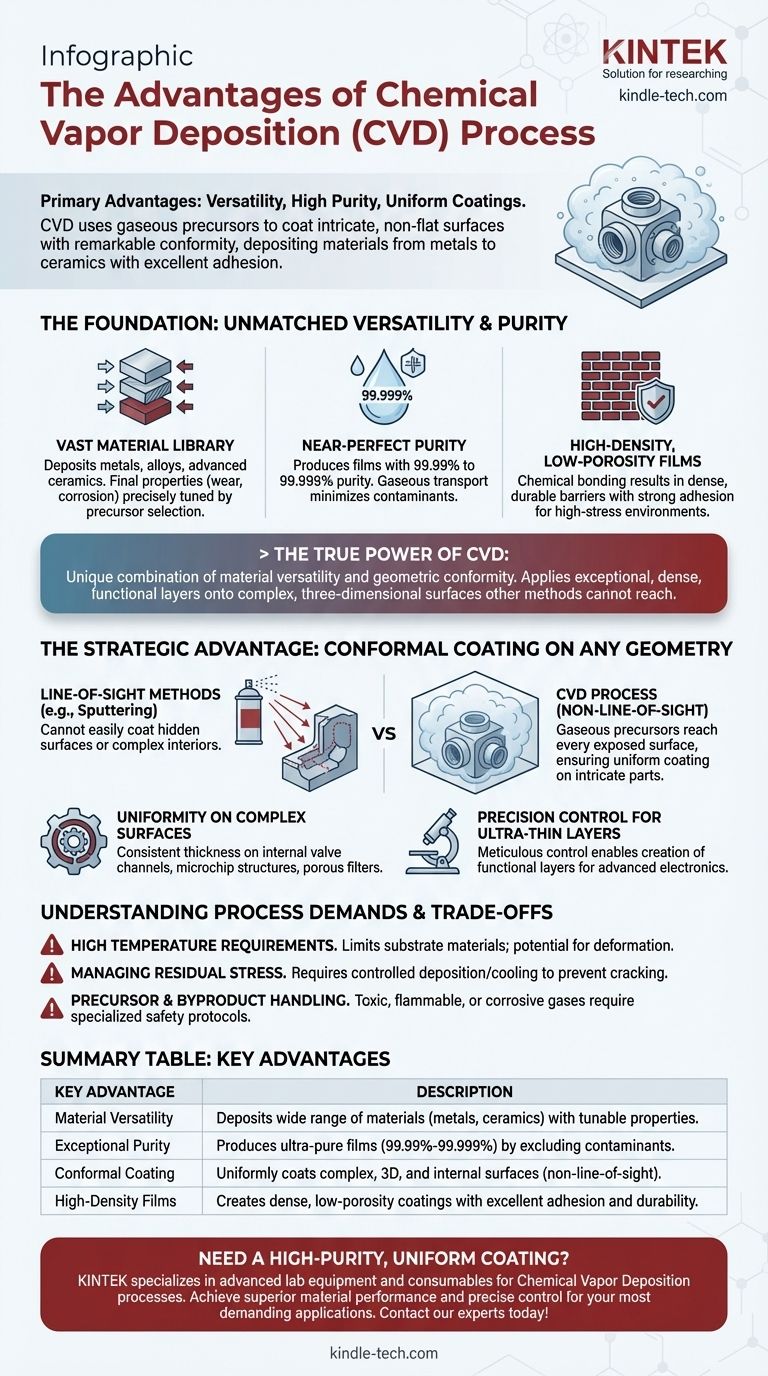

The primary advantages of Chemical Vapor Deposition (CVD) are its exceptional versatility, high purity, and unique ability to produce uniform, high-performance coatings. Unlike line-of-sight methods, CVD uses gaseous precursors that can penetrate and coat intricate, non-flat surfaces with remarkable conformity. This process can deposit a wide range of materials—from metals to ceramics—at high rates, resulting in dense, ultra-pure films with excellent adhesion.

The true power of CVD lies not in a single benefit, but in its unique combination of material versatility and geometric conformity. It solves the fundamental challenge of applying an exceptionally pure, dense, and functional layer of material onto complex, three-dimensional surfaces where other methods physically cannot reach.

The Foundation of CVD: Unmatched Versatility and Purity

The core strength of CVD comes from its foundation in chemistry. By using chemical reactions in a gaseous state, it unlocks a level of control and quality that is difficult to achieve with purely physical deposition methods.

A Vast Material Library

CVD is not limited to a small set of materials. The process can be adapted to deposit a wide array of elements and compounds, including metals, alloys, and advanced ceramics.

The final properties of the coating—such as wear resistance, lubricity, or corrosion resistance—can be precisely tuned by optimizing the precursor gases used in the reaction.

Achieving Near-Perfect Purity

The process is renowned for producing films with extremely high purity, often in the range of 99.99% to 99.999%.

Because the materials are transported as gases and react directly on the substrate surface, contaminants can be more easily excluded from the deposition chamber, leading to a purer final product.

Building High-Density, Low-Porosity Films

The chemical bonding that occurs during CVD results in coatings that are dense, with very low porosity and strong adhesion to the underlying material. This makes the films highly durable and effective as protective barriers, even when subjected to high-stress environments.

The Strategic Advantage: Conformal Coating on Any Geometry

Perhaps the most significant differentiator for CVD is its ability to coat everything it touches uniformly. This non-line-of-sight capability opens up applications that are impossible for other techniques.

Overcoming Line-of-Sight Limitations

Processes like sputtering or evaporation are "line-of-sight," meaning they work like a spray paint can and cannot easily coat hidden surfaces or the inside of a complex part.

CVD, however, behaves more like a fog that fills the entire chamber. The precursor gas molecules reach every exposed surface, ensuring that even intricate, irregular, or internal geometries receive a uniform coating.

Uniformity on Complex Surfaces

This property is critical for components with complex shapes, such as the internal channels of a valve, the intricate structures of a microchip, or the porous framework of a filter. CVD ensures the coating thickness is consistent across the entire part.

Precision Control for Ultra-Thin Layers

The process allows for meticulous control over the timing and rate of the chemical reaction. This enables the creation of ultra-thin, functional layers of material, a requirement for manufacturing advanced electrical circuits and semiconductors.

Understanding the Trade-offs and Process Demands

While powerful, CVD is not a universal solution. Its reliance on chemical reactions introduces specific requirements and potential challenges that must be managed for a successful outcome.

High Temperature Requirements

Many CVD processes require high temperatures to initiate and sustain the necessary chemical reactions. This can limit the types of substrate materials that can be used, as some may not withstand the heat without deforming or melting.

Managing Residual Stress

The difference in temperature between the deposition process and room temperature can introduce residual stress into the coated film. This requires careful control over deposition parameters and cooling rates to prevent cracking or delamination.

Precursor and Byproduct Handling

The precursor gases used in CVD can be toxic, flammable, or corrosive, requiring specialized handling and safety protocols. Furthermore, the chemical reactions often produce hazardous byproducts that must be safely managed and disposed of.

Making the Right Choice: When to Leverage CVD

Choosing a deposition method depends entirely on the specific requirements of your application. CVD excels where purity, conformity, and material quality are the primary drivers.

- If your primary focus is material purity and performance: CVD is an ideal choice for applications like semiconductors or optical components where even minor impurities can cause failure.

- If your primary focus is coating complex or internal surfaces: CVD's non-line-of-sight nature makes it the definitive solution for parts with intricate geometries that other methods cannot uniformly cover.

- If your primary focus is scalability for high-performance coatings: The process is economical for production runs, as many parts can be coated simultaneously in large batches with high manufacturing yield.

Ultimately, CVD is the process of choice when the chemical integrity and geometric conformity of a thin film are paramount to the final product's success.

Summary Table:

| Key Advantage | Description |

|---|---|

| Material Versatility | Deposits a wide range of materials (metals, ceramics) with tunable properties. |

| Exceptional Purity | Produces ultra-pure films (99.99%-99.999%) by excluding contaminants. |

| Conformal Coating | Uniformly coats complex, 3D, and internal surfaces (non-line-of-sight). |

| High-Density Films | Creates dense, low-porosity coatings with excellent adhesion and durability. |

Need a high-purity, uniform coating for complex components? KINTEK specializes in advanced lab equipment and consumables for Chemical Vapor Deposition processes. Our solutions help you achieve superior material performance, precise control, and reliable scalability for your most demanding applications. Contact our experts today to discuss how we can support your laboratory's coating and material science needs!

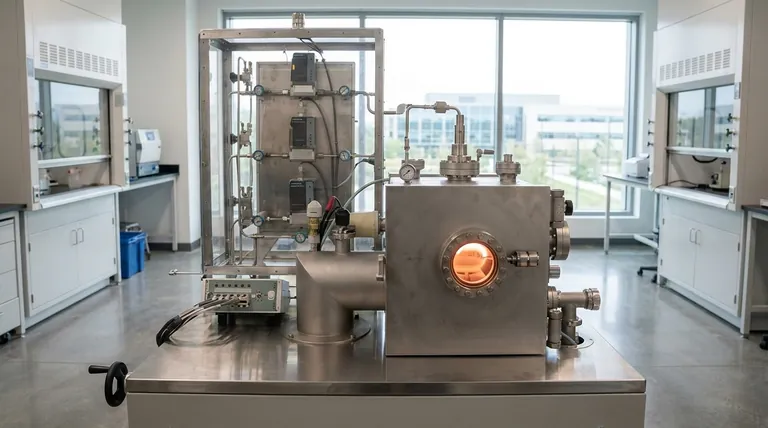

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application