Fundamentally, the primary advantage of a Diamond-Like Carbon (DLC) coating is its unique ability to impart extreme surface hardness, a very low coefficient of friction, and significant wear and corrosion resistance onto a component. It achieves this by creating a thin film that possesses both diamond-like (hard) and graphite-like (lubricious) properties.

While the benefits of DLC are numerous, its true value lies in solving critical engineering challenges related to friction and wear. It allows components to survive and perform in demanding applications, particularly where traditional lubrication is insufficient or absent.

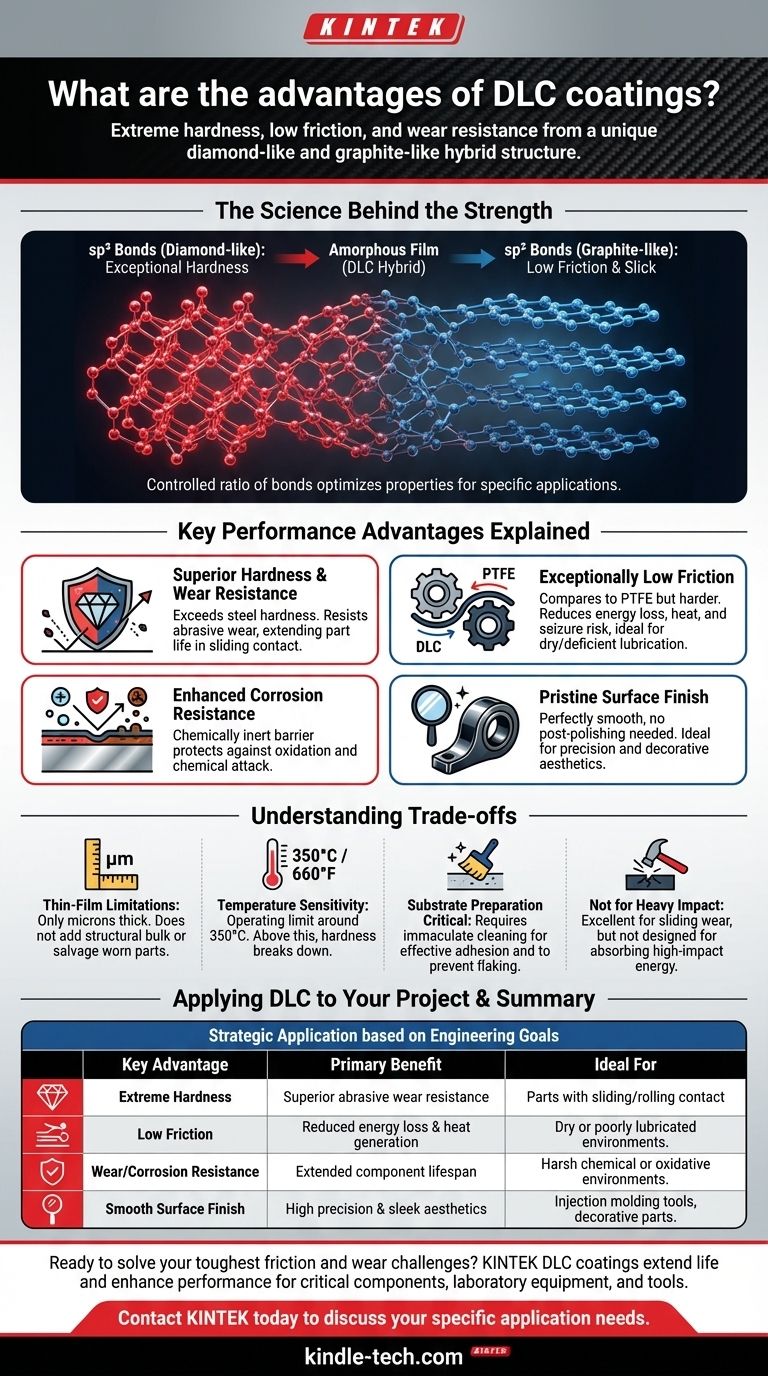

The Science Behind the Strength

A coating's performance is a direct result of its atomic structure. DLC is unique in how it combines two forms of carbon to deliver its signature properties.

A Hybrid Carbon Structure

DLC coatings are not pure diamond or pure graphite. Instead, they are an amorphous film containing a mixture of carbon atoms with sp³ bonds (the structure found in diamond) and sp² bonds (the structure found in graphite).

The ratio of these bonds can be controlled during the deposition process, allowing different types of DLC coatings to be optimized for specific applications.

The Resulting Physical Properties

This hybrid structure is the source of DLC's key advantages. The sp³ (diamond) content provides exceptional hardness, while the sp² (graphite) content provides a naturally slick, low-friction surface.

Key Performance Advantages Explained

The unique structure of DLC translates directly into measurable benefits for mechanical components and tools.

Superior Hardness and Wear Resistance

The high concentration of diamond-like bonds gives DLC coatings a hardness that can significantly exceed that of most steels. This makes them highly resistant to abrasive wear, extending the functional life of parts that experience rubbing or sliding contact.

Exceptionally Low Friction

DLC provides a very low coefficient of friction, often compared to that of PTFE (Teflon), but with much greater hardness. This is especially valuable in assemblies with sliding and rolling movements, as it reduces energy loss, heat generation, and the risk of seizure.

This property is a primary reason DLC excels in environments with dry or deficient lubrication, where other materials would quickly fail.

Enhanced Corrosion Resistance

The dense, chemically inert nature of the carbon film acts as a formidable barrier between the component's base material and corrosive environments. This protects the underlying part from oxidation and chemical attack.

Pristine Surface Finish

Many DLC processes result in a perfectly smooth surface finish that requires no post-treatment polishing. This makes it ideal for high-precision components, like injection molding tools, where dimensional accuracy and surface quality are critical. It also contributes to its use in decorative applications where a sleek, black finish is desired.

Understanding the Trade-offs

No material solution is perfect. Being a trusted advisor means acknowledging the limitations of DLC to ensure it is applied correctly.

Coating Thickness Limitations

DLC is a thin-film coating, typically only a few microns thick. It protects the surface from wear but will not add significant structural bulk or salvage a part that is already worn past its dimensional tolerance.

Temperature Sensitivity

While robust, most DLC coatings have an operating temperature limit, often around 350°C (660°F). Beyond this temperature, the beneficial carbon structure can begin to break down, reverting to softer graphite and losing its hardness.

Substrate Preparation is Critical

The performance of any coating is entirely dependent on its adhesion to the substrate. The component surface must be immaculately clean and properly prepared for the DLC to bond effectively. A poorly prepared surface will lead to premature flaking or delamination.

Not a Panacea for Impact

While extremely hard and wear-resistant, the thin nature of DLC means it is not an ideal solution for resisting heavy, direct impacts. Its strength lies in combating sliding and abrasive wear, not absorbing high-impact energy.

Applying DLC to Your Project

To determine if DLC is the right choice, you must first define your primary engineering goal.

- If your primary focus is maximizing component lifespan: Use DLC to combat abrasive wear and friction, especially in assemblies with constant sliding or rolling contact.

- If your primary focus is improving efficiency or reliability: Leverage DLC's low coefficient of friction to reduce energy loss and heat, particularly in applications where lubrication is minimal or inconsistent.

- If your primary focus is part precision or a durable aesthetic: Choose a DLC formulation for its ability to provide a sleek black finish with superior scratch resistance without requiring post-processing.

By understanding its core strengths and limitations, you can strategically apply DLC to solve some of your most demanding engineering challenges.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Extreme Hardness | Superior resistance to abrasive wear | Parts with sliding/rolling contact |

| Low Friction | Reduced energy loss & heat generation | Dry or poorly lubricated environments |

| Wear/Corrosion Resistance | Extended component lifespan | Harsh chemical or oxidative environments |

| Smooth Surface Finish | High precision and sleek aesthetics | Injection molding tools, decorative parts |

Ready to solve your toughest friction and wear challenges?

DLC coatings from KINTEK can significantly extend the life and enhance the performance of your critical components. Our expertise in advanced surface solutions ensures your laboratory equipment and tools operate with maximum efficiency and reliability, even in the most demanding conditions.

Contact KINTEK today to discuss how our specialized DLC coatings can be tailored to your specific application needs.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- How much does DLC coating cost? A Detailed Breakdown of Pricing Factors

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- How is diamond-like coating applied? A Guide to PVD vs. PACVD Methods

- What is the temperature of plasma enhanced CVD? Achieve High-Quality Deposition on Temperature-Sensitive Substrates

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is PECVD in solar cells? The Key to High-Efficiency Anti-Reflection and Passivation

- How are wafers and electrodes configured within a PECVD system? Mastering Parallel-Plate Architecture

- What is the advantage of VHF-PECVD over RF-PECVD? Maximize Deposition Rates for Advanced Thin Film Growth