In a direct comparison, a hydraulic press offers superior flexibility, built-in overload protection, and lower initial and long-term costs. Its ability to deliver full, constant force at any point in its stroke makes it exceptionally versatile, while its simpler design with fewer moving parts leads to quieter operation and easier maintenance compared to its mechanical counterpart.

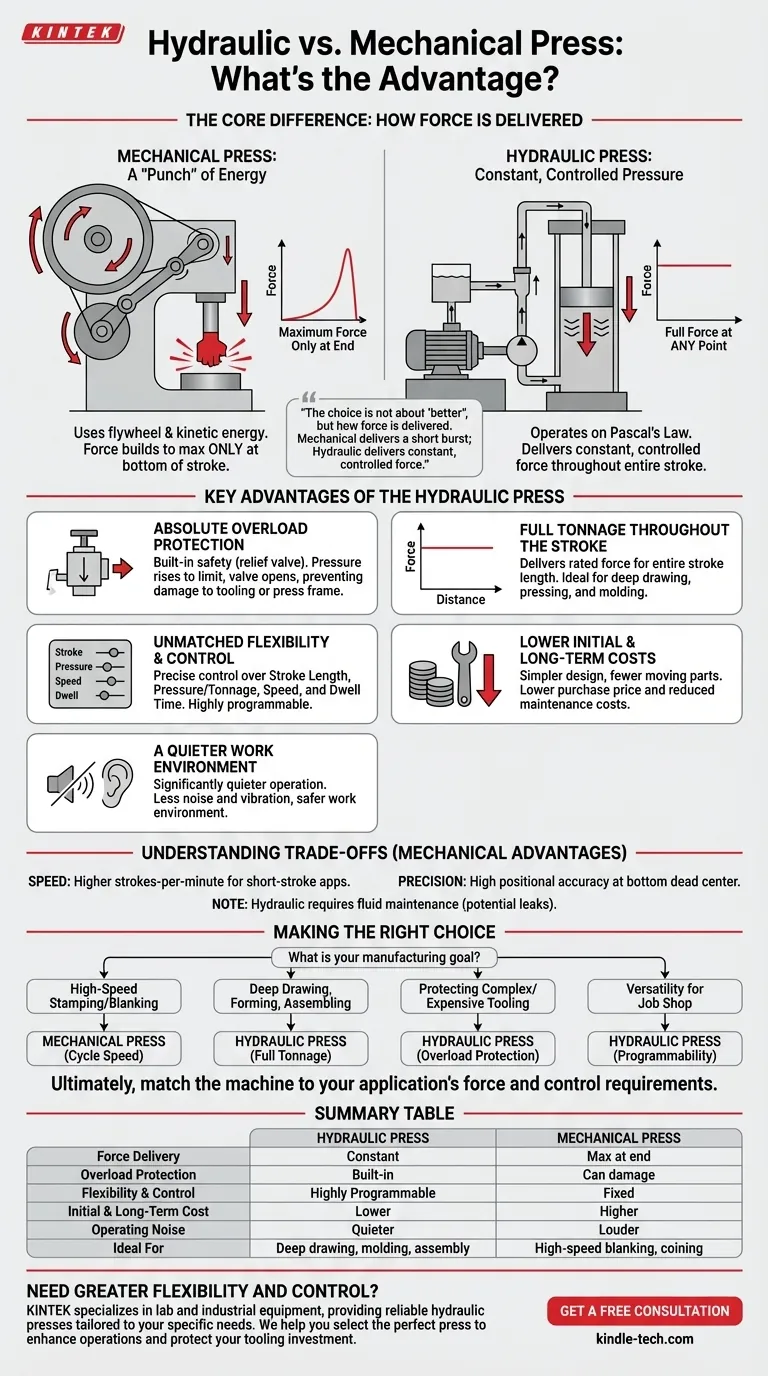

The choice between a hydraulic and mechanical press is not about which is "better," but about how each machine delivers force. A mechanical press delivers a short burst of maximum force only at the end of its stroke, while a hydraulic press delivers constant, controlled force throughout its entire stroke.

The Core Difference: How Force is Delivered

To understand the advantages of a hydraulic press, you must first understand the fundamental difference in how each machine type functions. This single distinction is the source of all their respective strengths and weaknesses.

The Mechanical Press: A "Punch" of Energy

A mechanical press uses a motor to spin a heavy flywheel, which stores kinetic energy. When engaged, a clutch connects the flywheel to a crankshaft that drives the ram down in a fixed-motion stroke.

The force is not constant. It builds to its maximum rated tonnage only at the very bottom of the stroke, making it ideal for applications that require a massive "punch" in a single moment, like blanking or punching metal sheet.

The Hydraulic Press: Constant, Controlled Pressure

A hydraulic press operates on a basic principle: Pascal's Law. An electric motor drives a pump that moves hydraulic fluid into a cylinder, pushing a piston down and generating force.

This force is generated by pressure and is available at its maximum rating at any point during the ram's travel—top, middle, or bottom. The amount of force, the speed of the stroke, and the duration it is applied (dwell time) are all fully programmable.

Key Advantages of the Hydraulic Press Explained

The hydraulic press's method of generating force creates several significant operational advantages for a wide range of applications.

Absolute Overload Protection

Because force is directly related to fluid pressure, a hydraulic press has a built-in safety mechanism. A simple relief valve can be set to a maximum pressure.

If the press encounters an obstacle or is set up incorrectly, the fluid pressure will rise to the set limit and then the valve will open, preventing any damage. A mechanical press, in contrast, will continue its stroke with immense force, which can destroy expensive tooling or even crack the press frame.

Full Tonnage Throughout the Stroke

This is arguably the most significant advantage. Applications like deep drawing, pressing, or molding require sustained force over a long distance to properly form the material.

A hydraulic press delivers its full rated force for the entire stroke length. A 100-ton hydraulic press is a 100-ton press from start to finish, while a 100-ton mechanical press is only a 100-ton press for the last fraction of an inch of its travel.

Unmatched Flexibility and Control

Modern hydraulic presses offer precise control over every aspect of the stroke. You can easily adjust:

- Stroke Length: Set the top and bottom positions anywhere within the press's travel.

- Pressure/Tonnage: Dial in the exact force needed for the job.

- Speed: Program different speeds for the approach, pressing, and return phases.

- Dwell Time: Set the press to hold full pressure at the bottom of the stroke for any length of time.

This programmability makes a single hydraulic press capable of handling a vast range of jobs with highly accurate and repeatable results.

Lower Initial and Long-Term Costs

Hydraulic presses have a simpler design with far fewer moving parts than a mechanical press. They do not have a flywheel, clutch, brake, or complex gear systems.

This simplicity results in a lower purchase price for a given tonnage and significantly reduced long-term maintenance costs, as there are fewer components to wear out and replace.

A Quieter Work Environment

The powerful impact of a mechanical press generates significant noise and vibration with every stroke. A hydraulic press, by contrast, is much quieter, with noise primarily coming from the motor and pump, resulting in a less fatiguing and safer work environment.

Understanding the Trade-offs

No machine is perfect for every task. To maintain objectivity, it is critical to understand where a mechanical press holds an advantage.

Speed: The Mechanical Advantage

For high-volume, short-stroke applications like blanking or shallow stamping, a mechanical press is often much faster. Its fixed cycle time allows it to achieve very high strokes-per-minute rates that a hydraulic press cannot match.

Precision at the Bottom of the Stroke

Because its stroke length is determined by a physical crankshaft, a mechanical press offers extremely high positional accuracy at the very bottom of its stroke (bottom dead center). This can be beneficial for coining or sizing operations where final part thickness is absolutely critical.

Potential for Fluid Leaks

The primary maintenance concern for any hydraulic system is the potential for fluid leaks from seals, hoses, or fittings. While modern systems are highly reliable, this remains a factor to consider in upkeep.

Making the Right Choice for Your Application

The decision ultimately comes down to matching the machine's capabilities to your manufacturing goal.

- If your primary focus is high-speed stamping or blanking: The cycle speed and impact force of a mechanical press is likely the superior choice.

- If your primary focus is deep drawing, forming, or assembling: The full tonnage throughout the stroke and process control of a hydraulic press is essential.

- If your primary focus is protecting complex and expensive tooling: The built-in overload protection of a hydraulic press provides invaluable insurance against damage.

- If your primary focus is versatility for a job shop environment: The programmability and flexibility of a hydraulic press allow it to adapt to the widest variety of tasks.

Ultimately, choosing the correct press technology requires a clear understanding of your application's specific force and control requirements.

Summary Table:

| Advantage | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Delivery | Constant, full force at any point in stroke | Maximum force only at bottom of stroke |

| Overload Protection | Built-in (pressure relief valve) | Can damage tooling/frame |

| Flexibility & Control | Highly programmable (speed, pressure, dwell) | Fixed stroke, limited adjustability |

| Initial & Long-Term Cost | Lower | Higher |

| Operating Noise | Quieter | Louder (impact noise) |

| Ideal For | Deep drawing, forming, molding, assembly | High-speed blanking, punching, coining |

Need a Press That Offers Greater Flexibility and Control?

Choosing the right press is critical for your productivity and bottom line. The advantages of a hydraulic press—like full-force control, built-in overload protection, and lower costs—make it the ideal solution for forming, molding, and assembly tasks.

KINTEK specializes in lab and industrial equipment, providing reliable hydraulic presses tailored to your specific needs. Whether you're in a job shop requiring versatility or a production environment needing precise control, we can help you select the perfect press to enhance your operations and protect your tooling investment.

Contact us today to discuss your application and find the right hydraulic press for your workshop or production line.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- How does a laboratory hydraulic press ensure performance consistency for LDPC? Achieve Uniform Ceramic Substrates

- Do hydraulics need lubrication? Why Hydraulic Fluid is the Multi-Tasking Lifeblood of Your System

- What is the temperature of a hydraulic system? Maintain Optimal Performance & Prevent Damage

- How does a laboratory hydraulic press ensure the quality of sulfide electrolyte pellets? Optimize Ion Transport

- What is the role of KBr in IR? Achieve High-Resolution Spectra for Solid Samples

- What are the industrial applications of plate and frame filter press? A Guide to Efficient Solid-Liquid Separation

- How do you increase the speed of a hydraulic press? Boost Cycle Times & Productivity

- What is the High Pressure High Temperature (HPHT) process for creating diamonds? Replicate Earth's Mantle in the Lab