The primary advantage of an induction coil is its ability to generate rapid, precise, and highly efficient heat directly within a target material without any physical contact. This is achieved by using electromagnetic induction to create an alternating magnetic field, which in turn induces electrical currents inside the conductive workpiece, causing it to heat itself from the inside out.

At its core, induction heating is fundamentally different from traditional methods. Instead of applying heat from an external source like a flame or heating element, it turns the material itself into the source of heat, granting unparalleled control and efficiency.

The Core Principle: Heating from Within

To understand the advantages of induction, you must first understand its unique mechanism. The technology relies on two core physics principles working in tandem.

The Phenomenon of Electromagnetic Induction

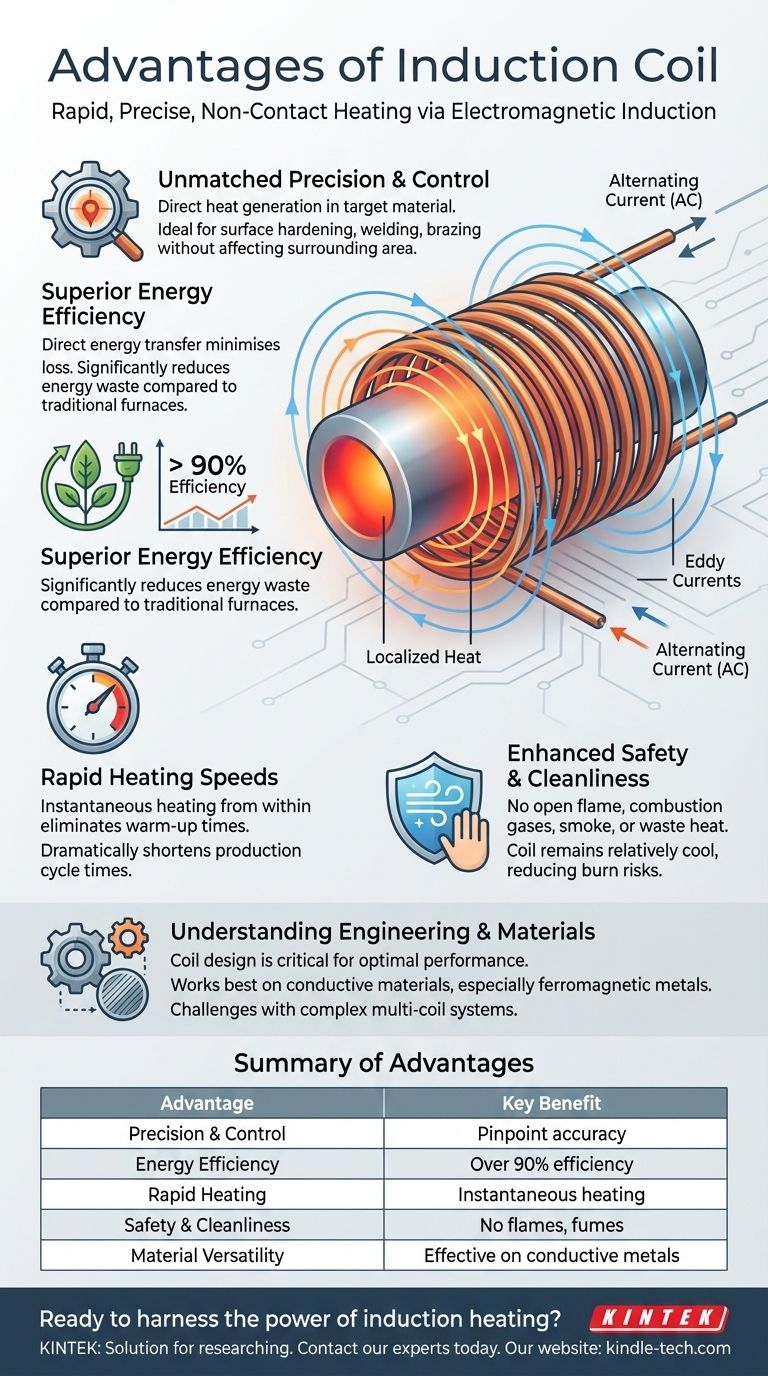

An induction coil is a simple coil of conductive wire, typically copper. When a high-frequency alternating current (AC) is passed through this coil, it generates a powerful and rapidly changing magnetic field around it.

Generating Internal Heat

When a conductive material, such as a piece of metal, is placed within this magnetic field, the field induces electrical currents (known as eddy currents) within the metal. The material's natural resistance to the flow of these currents generates immense, localized heat.

The Practical Advantages of Induction

This "heating from within" mechanism is the source of all of induction's key benefits, making it a transformative technology in both industrial and domestic settings.

Unmatched Precision and Control

Because the heat is generated directly where the magnetic field is strongest, you can control the heating location with extreme accuracy. This is critical for applications like surface hardening, welding, or brazing specific joints without affecting the surrounding material.

Superior Energy Efficiency

Traditional furnaces waste enormous amounts of energy heating the furnace walls and the air around the target object. Induction transfers energy directly to the workpiece with minimal loss, often resulting in energy efficiencies exceeding 90%.

Rapid Heating Speeds

The heating is direct and instantaneous. There is no need to wait for a furnace to warm up or for heat to slowly conduct from the outside in. This dramatically reduces cycle times in manufacturing processes.

Enhanced Safety and Cleanliness

Induction heating is a remarkably clean process. There are no combustion gases, smoke, or waste heat, leading to a safer and more comfortable working environment. The coil itself remains relatively cool, reducing the risk of burns.

Understanding the Engineering Considerations

While powerful, induction technology is not a universal solution. Its effectiveness is highly dependent on proper engineering and understanding its limitations.

The Critical Role of Coil Design

The shape, size, and geometry of the induction coil are paramount. The coil must be carefully designed to match the workpiece to ensure the magnetic field is concentrated precisely where the heat is needed for optimal performance.

Challenges of Multi-Coil Systems

For complex parts or large surfaces, multiple coils can be used to ensure uniform heat distribution. However, this introduces complexity, as the magnetic fields of individual coils can interfere with each other, requiring advanced power converters and control algorithms to manage.

Material Compatibility

Induction heating works best on electrically conductive materials. It is most effective on ferromagnetic metals like iron and steel due to their additional magnetic properties, but it can also be used for non-ferrous metals like copper and aluminum, albeit with different efficiency characteristics.

Making the Right Choice for Your Application

The decision to use induction heating depends entirely on your specific goals and the materials involved.

- If your primary focus is precision manufacturing: The ability to precisely localize heat for processes like case hardening, brazing, or tempering is the standout advantage.

- If your primary focus is high-volume production: The incredible speed and energy efficiency of induction heating will dramatically reduce cycle times and operational costs.

- If your primary focus is domestic cooking or safety: The lack of an open flame, the cool cooktop surface, and the rapid response time make it an ideal choice for modern kitchens.

Ultimately, harnessing the power of an induction coil allows you to place heat exactly where you need it, when you need it, with minimal waste.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision & Control | Heat is generated directly within the target material for pinpoint accuracy. |

| Energy Efficiency | Direct energy transfer to the workpiece achieves efficiencies over 90%. |

| Rapid Heating | Instantaneous heating from within eliminates warm-up times. |

| Safety & Cleanliness | No open flame, fumes, or waste heat; coil remains cool. |

| Material Versatility | Effective on conductive metals like steel, copper, and aluminum. |

Ready to harness the power of induction heating in your lab or production line?

At KINTEK, we specialize in providing high-performance lab equipment, including advanced induction heating solutions tailored to your specific needs. Whether you're in precision manufacturing, high-volume production, or require safe and efficient heating for research, our expertise ensures you get the right system for maximum efficiency and control.

Contact our experts today to discuss how our induction heating technology can revolutionize your processes, reduce costs, and enhance safety.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Lab-Scale Vacuum Induction Melting Furnace

- Three-dimensional electromagnetic sieving instrument

- Gold Disc Electrode

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- How does a vacuum hot pressing furnace facilitate nanocrystalline structures? Enhance Fe–Cu–Ni–Sn–VN Composite Hardness

- How does the vacuum hot pressing process improve wettability? Unlock Superior Diamond Product Bonding Strength

- How does the vacuum environment within a hot-pressing furnace improve the performance of B4C/Al composites? Boost Density

- Why is a high-precision temperature control system in a vacuum hot press furnace critical? Perfect Cu-Ti3SiC2 Synthesis

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity