The primary advantages of induction heating are its exceptional speed, precision, and energy efficiency. Unlike traditional furnaces that heat parts from the outside in, induction generates heat directly within the material itself, allowing for targeted, rapid, and highly repeatable thermal processing.

Induction heating's core value lies in its ability to transform electrical energy into targeted heat inside a workpiece. This fundamental difference from conventional heating methods is the source of its most significant manufacturing advantages in control, speed, and efficiency.

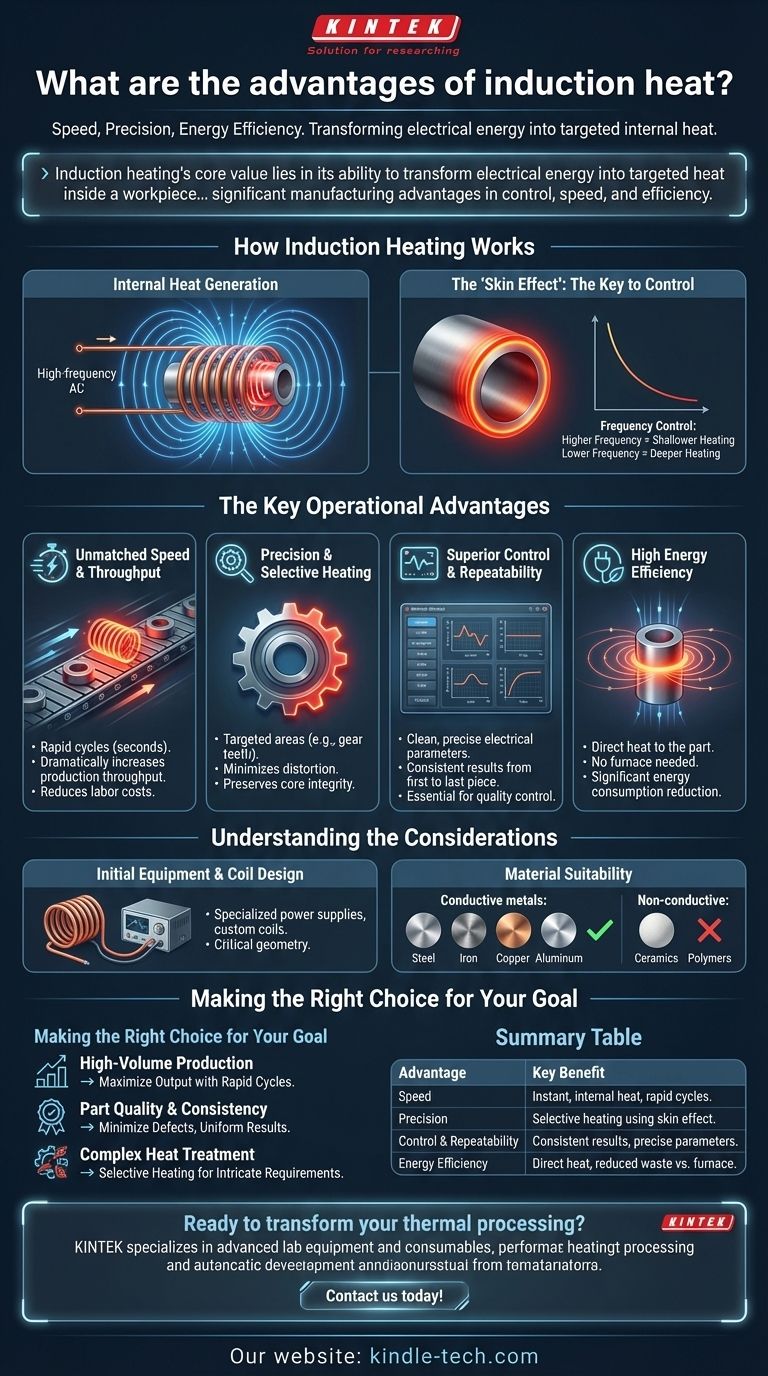

How Induction Heating Works

The Core Principle: Internal Heat Generation

An induction system uses a copper coil, called an inductor, through which a high-frequency alternating current is passed.

This current creates a powerful and rapidly changing magnetic field around the coil. When a conductive workpiece, such as a steel part, is placed inside this field, it induces electrical eddy currents within the metal.

The "Skin Effect": The Key to Control

These eddy currents flow primarily on the surface of the part, a phenomenon known as the skin effect. The resistance of the metal to the flow of this current generates intense, localized heat.

Crucially, the depth to which these currents penetrate can be precisely controlled by adjusting the frequency of the alternating current. A higher frequency results in shallower heating, while a lower frequency heats deeper into the material.

The Key Operational Advantages

Unmatched Speed and Throughput

Because heat is generated instantly and directly within the part, heating cycles are incredibly short—often lasting just a few seconds.

This rapid heating dramatically increases production throughput compared to the long ramp-up and soak times required by conventional furnaces, reducing labor costs and improving workflow.

Precision and Selective Heating

Induction allows you to heat only a specific area of a part. For example, you can harden the teeth of a gear without altering the metallurgical properties of its core.

This selective capability minimizes the risk of part distortion and preserves the integrity of areas that do not require treatment, resulting in a higher quality finished product.

Superior Control and Repeatability

The induction process is governed by clean, precise electrical parameters: current, frequency, and time.

Once these variables are set for a specific part, the results are exceptionally consistent from the first piece to the last. This high degree of repeatability is essential for modern quality control standards.

High Energy Efficiency

Induction heating is a highly efficient process because energy is only expended on the part being heated, and only in the specific area needed.

There is no need to heat a massive furnace chamber or maintain it at high temperatures for extended periods, leading to significant reductions in energy consumption.

Understanding the Considerations

Initial Equipment and Coil Design

Implementing induction heating requires specialized power supplies and custom-designed inductor coils. The geometry of the coil is critical and must be carefully engineered to match the part for optimal results.

This initial investment in equipment and design is a key consideration, though it is often offset by long-term gains in throughput and energy savings.

Material Suitability

The process relies on inducing an electrical current within the material, meaning it is best suited for conductive metals like steel, iron, copper, and aluminum.

Non-conductive materials like ceramics or certain polymers cannot be heated directly by induction and would require different methods.

Making the Right Choice for Your Goal

The decision to use induction heating should be based on your primary manufacturing objectives.

- If your primary focus is high-volume production: The exceptionally short cycle times and rapid throughput of induction heating are ideal for maximizing output.

- If your primary focus is part quality and consistency: The precise, repeatable control over heating depth and location minimizes defects and ensures uniform results across every part.

- If your primary focus is complex heat treatment: The ability to selectively heat specific zones on a part without affecting others makes it perfect for components with intricate hardening requirements.

Ultimately, choosing induction heating is a strategic decision that trades initial investment for unparalleled control, speed, and long-term operational efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed | Instant, internal heat generation for rapid cycles (seconds). |

| Precision | Selective heating of specific part areas using the skin effect. |

| Control & Repeatability | Consistent results governed by precise electrical parameters. |

| Energy Efficiency | Direct heat to the part reduces energy waste versus furnace heating. |

Ready to transform your thermal processing with the precision and speed of induction heating? KINTEK specializes in advanced lab equipment and consumables, providing solutions that enhance manufacturing throughput, part quality, and energy efficiency. Whether your focus is high-volume production or complex heat treatment, our expertise can help you achieve unparalleled control and consistency. Contact us today to discuss how our induction heating solutions can meet your specific laboratory and production needs!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Double Plate Heating Press Mold for Lab

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What are the advantages of using a vacuum hot pressing furnace? Achieve Superior Density in Cu-Y Composites

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What role does the vacuum hot-press furnace play in C-SiC-B4C-TiB2 synthesis? Achieve 2000°C Precision Densification