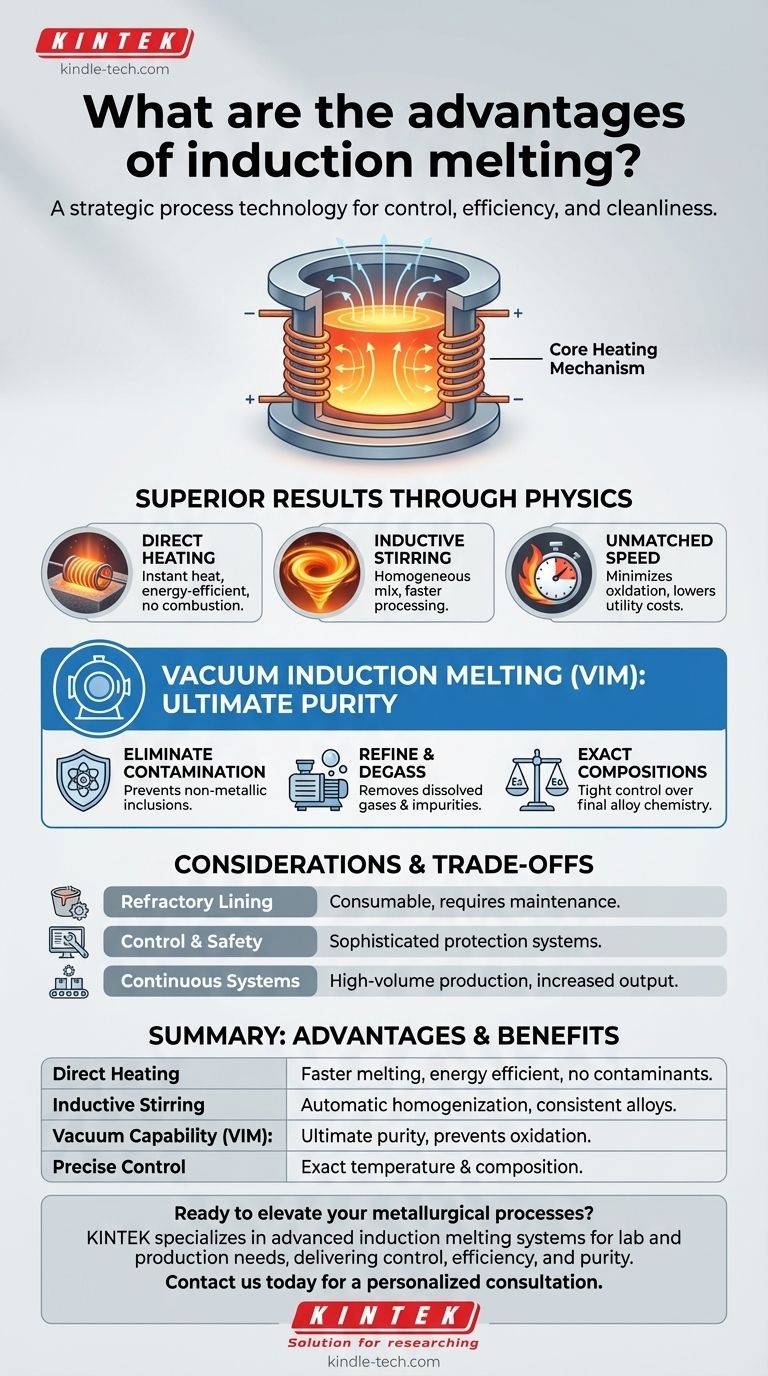

At its core, induction melting offers a faster, more efficient, and cleaner method for melting metals compared to traditional fuel-fired furnaces. The primary advantages stem from its unique heating mechanism, which uses electromagnetic fields to generate heat directly within the metal itself, providing unparalleled control over the entire process from start to finish.

Induction melting is not just another way to melt metal; it is a strategic process technology. Its fundamental advantages in control, efficiency, and cleanliness directly translate to higher quality products, reduced operational costs, and greater metallurgical precision.

How Induction Delivers Superior Results

The benefits of induction melting are a direct result of its underlying physics. Unlike conventional furnaces that heat a crucible from the outside, induction creates heat within the charge material, leading to a fundamentally more controlled environment.

The Advantage of Direct Heating

An induction coil generates a powerful, alternating magnetic field. When conductive material like metal is placed within this field, it induces electrical currents (known as eddy currents) that flow through the metal, generating precise and rapid heat due to electrical resistance. This process is clean, as it involves no combustion, no exhaust gases, and no byproducts to contaminate the melt.

Inherent Inductive Stirring

The same magnetic fields that generate heat also create a stirring action within the molten bath. This inductive stirring is a significant, built-in advantage, as it automatically ensures a highly homogeneous mix. This is critical for creating consistent alloys and accelerates the dissolution of alloying elements, reducing overall processing time.

Unmatched Speed and Energy Efficiency

Because heat is generated directly within the metal, melting begins almost instantly and proceeds much faster than in furnaces that rely on thermal radiation and convection. This speed minimizes the time metal is held at high temperatures, reducing the chance for gas pickup or the loss of valuable elements through oxidation. The direct heating process is also far more energy-efficient, lowering overall utility costs.

Vacuum Induction Melting (VIM): For Ultimate Purity

For applications demanding the highest material quality—such as superalloys for aerospace or medical implants—Vacuum Induction Melting (VIM) takes the advantages a step further by performing the melt inside a controlled vacuum or inert gas atmosphere.

Eliminating Atmospheric Contamination

The primary benefit of VIM is the removal of oxygen and nitrogen from the process. This prevents the formation of non-metallic oxide inclusions, which are common defects that compromise the mechanical properties of an alloy. It is the only reliable method for melting alloys containing highly reactive elements like titanium and aluminum without them being lost to oxidation.

Refining and Degassing the Melt

Operating under a vacuum actively pulls unwanted elements out of the molten metal. This includes dissolved gases like hydrogen and nitrogen as well as trace elements with high vapor pressures. The result is a cleaner, more refined metal with superior structural integrity and predictable performance.

Achieving Exact Compositions

VIM allows for extremely tight control over the final alloy chemistry. Without the risk of oxidation or contamination from a protective slag cover, metallurgists can achieve precise compositional tolerances. This, combined with precise temperature control, makes VIM the gold standard for producing materials with demanding specifications.

Understanding the Trade-offs and Considerations

While powerful, induction technology requires a clear understanding of its operational demands to be leveraged effectively.

The Importance of the Refractory Lining

The crucible holding the molten metal, known as the refractory lining, is a critical component that wears over time and is considered a consumable. The choice of material (e.g., high-purity alumina) and a strict maintenance schedule are essential for preventing furnace failure and melt contamination.

Control and Safety Systems

Modern induction furnaces are equipped with sophisticated protection systems. These monitor water pressure for the cooling circuits, watch for overheating conditions, and manage power delivery. Proper operation and maintenance of these systems are non-negotiable for ensuring safe and reliable production.

Throughput with Continuous Systems

For high-volume production, a standard batch process can create bottlenecks while waiting for charging, melting, and cooling. Continuous or semi-continuous VIM systems address this by allowing operations like charging and pouring to occur without stopping the furnace, dramatically increasing production efficiency and alloy output.

Making the Right Choice for Your Goal

Selecting the right induction process depends entirely on your end-product requirements and operational priorities.

- If your primary focus is cost-effective, high-volume melting (e.g., scrap recycling, standard foundries): A conventional atmosphere induction furnace provides the best balance of speed, energy efficiency, and high metal recovery.

- If your primary focus is producing high-purity or complex alloys (e.g., aerospace, medical): Vacuum Induction Melting (VIM) is non-negotiable for achieving the required cleanliness, compositional accuracy, and material properties.

- If your primary focus is maximizing production throughput for high-value alloys: A continuous or semi-continuous VIM system will deliver the highest output by minimizing downtime between melts.

Ultimately, adopting induction technology is a decision to prioritize control, quality, and efficiency in your metallurgical operations.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Direct Heating | Faster melting, higher energy efficiency, no combustion contaminants |

| Inductive Stirring | Automatic homogenization for consistent alloys and faster processing |

| Vacuum Capability (VIM) | Ultimate purity by removing gases and preventing oxidation |

| Precise Control | Exact temperature and composition control for superior metallurgy |

Ready to elevate your metallurgical processes with the precision of induction melting?

KINTEK specializes in advanced lab equipment, including induction melting systems tailored for your specific needs—whether for high-volume foundry work or ultra-pure Vacuum Induction Melting (VIM) for aerospace and medical alloys. Our solutions deliver the control, efficiency, and purity you need for higher quality products and reduced operational costs.

Contact us today to discuss how our induction melting technology can transform your lab or production facility. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What metals work with induction heating? Understanding Magnetic & Electrical Properties for Efficient Heating

- How can the total required kilowatt-hours (kWh) for a melting process be calculated? Master Your Energy Estimation

- Can an induction heater melt metal? A Guide to Fast, Clean, and Controlled Melting

- What is induction heat for brazing? Achieve Precise, Rapid Metal Joining

- What role does a Vacuum Induction Melting furnace play in 12% Cr martensitic steel? Achieve Ultra-Pure Alloy Control

- What is the VAR process of steel? Achieve Superior Purity and Performance for Critical Components

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- How to choose an induction furnace? A Guide to Matching Capacity, Power, and Frequency