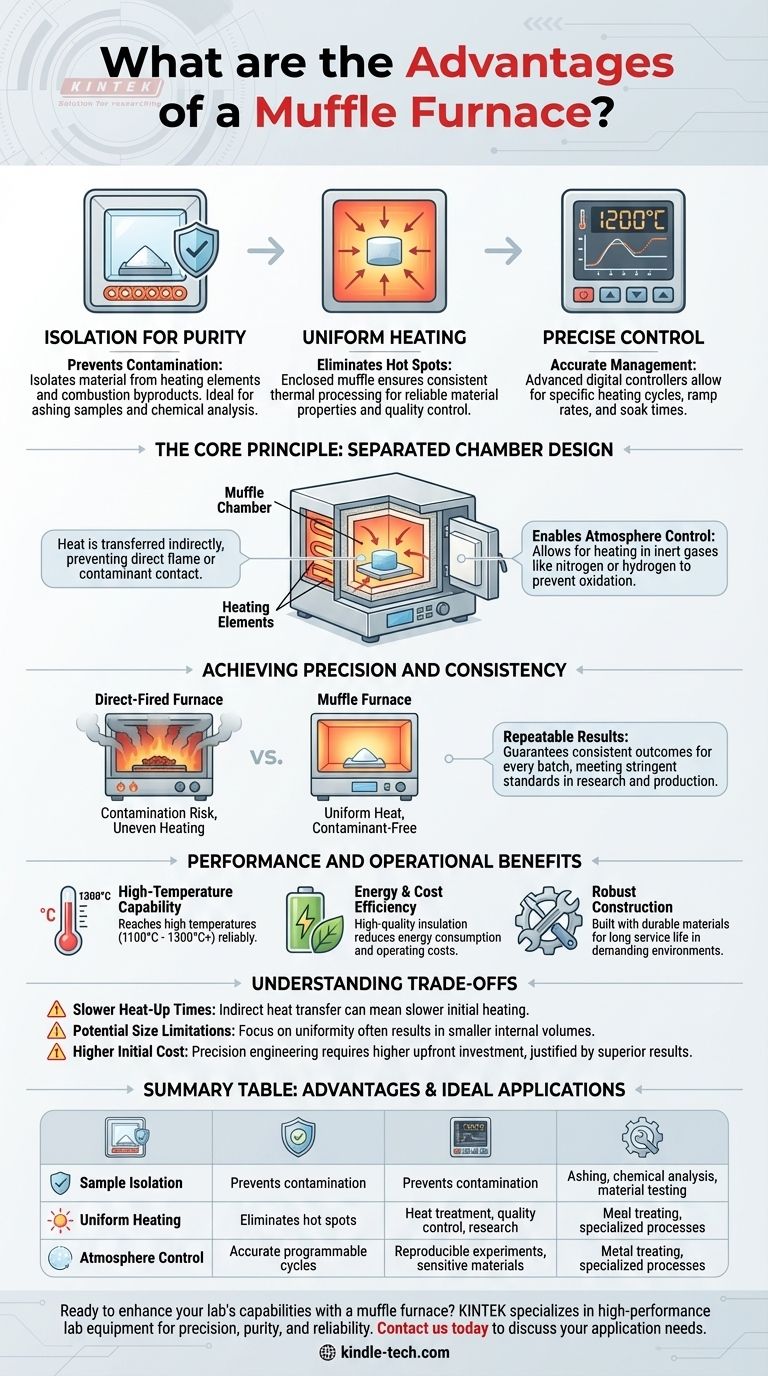

In essence, a muffle furnace provides three primary advantages: it isolates the material being heated from contaminants, delivers exceptionally uniform heat, and maintains precise temperature control. These benefits make it an indispensable tool for applications where the purity and structural integrity of the final product are critical.

The core value of a muffle furnace is not simply reaching high temperatures. Its true advantage lies in creating a perfectly controlled, clean, and uniform heating environment, ensuring that your results are repeatable and your materials remain uncontaminated.

The Core Principle: Isolating the Sample for Purity

A muffle furnace's primary advantage comes from its fundamental design, which is centered around a separated heating chamber.

What is the "Muffle"?

The term muffle refers to the inner chamber that houses the material being heated. This chamber is isolated from the actual heating elements and any fuel combustion byproducts.

Heat is transferred through the walls of the muffle to the sample inside, rather than being applied directly.

Preventing Contamination

This separation is crucial for sample purity. In direct-fired furnaces, byproducts of combustion can interact with and contaminate the workpiece.

A muffle furnace completely eliminates this risk, making it ideal for processes like ashing samples for chemical analysis, where any foreign material would skew the results.

Enabling Atmosphere Control

Because the chamber is sealed, you can control the atmosphere within it. This allows for heating in specific environments, such as inert gases like nitrogen or hydrogen.

This capability is vital for heat-treating metals and other materials that would otherwise oxidize or react undesirably with air at high temperatures.

Achieving Precision and Consistency

Beyond purity, a muffle furnace is engineered for repeatable, high-quality thermal processing.

Uniform Heat Distribution

The enclosed muffle chamber radiates heat evenly onto the sample from all sides. This design minimizes hot spots and temperature gradients.

Uniform heating ensures that the entire workpiece undergoes the exact same thermal process, which is critical for consistent material properties, testing, and quality control.

Precise Temperature Control

Modern muffle furnaces are equipped with sophisticated digital controllers and thermocouples. This allows for highly precise temperature management, often within a few degrees of the setpoint.

Users can program complex heating cycles with specific ramp rates (how quickly temperature rises), soak times (how long it's held), and cooling rates.

The Impact on Repeatable Results

The combination of uniform heating and precise control guarantees that results are consistent and accurate.

Whether in a research lab or a production facility, this repeatability ensures that each batch meets the same stringent standards.

Performance and Operational Benefits

Beyond its core scientific functions, a muffle furnace is also designed to be a practical and durable piece of equipment.

High-Temperature Capability

Muffle furnaces are built to operate reliably at very high temperatures, with many common models reaching 1100°C to 1300°C (2012°F to 2372°F) or more.

Energy and Cost Efficiency

High-quality insulation materials are used to retain heat within the furnace. This excellent thermal insulation reduces energy consumption, making the furnace more cost-effective to operate over its lifetime.

Robust Construction and Longevity

These furnaces are typically built with durable, high-heat-resistant materials. Their robust design ensures a long service life even under demanding daily use in industrial or laboratory settings.

Understanding the Trade-offs

While highly advantageous, no tool is perfect for every scenario. It is important to understand the inherent trade-offs.

Slower Heat-Up Times

Because the heat must transfer indirectly through the muffle chamber walls, these furnaces can have slower initial heat-up and cool-down times compared to direct-fired furnaces.

Potential Size Limitations

The design, which prioritizes uniformity and isolation, often results in a smaller internal chamber volume compared to larger, industrial bulk-processing ovens.

Higher Initial Cost

The precision engineering, high-quality insulation, and control systems can lead to a higher upfront investment compared to simpler, less precise ovens. However, this cost is often justified by the superior results and operational efficiency.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on your end goal.

- If your primary focus is analytical purity (e.g., ashing, gravimetric analysis): A muffle furnace is essential, as its isolation prevents contamination that would invalidate your results.

- If your primary focus is heat-treating sensitive materials or alloys: The uniform heating and atmosphere control of a muffle furnace are critical for achieving desired material properties without oxidation.

- If your primary focus is simple drying or heating non-sensitive items: A less expensive laboratory oven or convection furnace may be sufficient if contamination and perfect uniformity are not concerns.

Ultimately, choosing a muffle furnace is a decision to prioritize precision, purity, and repeatability in your thermal processes.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Sample Isolation | Prevents contamination from heating elements/combustion | Ashing, chemical analysis, material testing |

| Uniform Heating | Eliminates hot spots for consistent results | Heat treatment, quality control, research |

| Precise Control | Accurate temperature & programmable cycles | Reproducible experiments, sensitive materials |

| Atmosphere Control | Heat in inert gases to prevent oxidation | Metal treating, specialized processes |

Ready to enhance your lab's capabilities with a muffle furnace?

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for precision, purity, and reliability. Whether you're in research, quality control, or production, our solutions ensure your thermal processes deliver accurate, repeatable results every time.

Contact us today to discuss your specific application needs and discover the perfect furnace for your lab. Get in touch now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is a high-temperature furnace essential for catalyst preparation? Unlock peak catalytic activity and stability.

- What role does a high-temperature muffle furnace play in the production of inorganic metal oxide nanofibers?

- What is the function of high-temperature digestion furnaces and lithium borate fluxes? Expert REE Sample Preparation

- How do I choose a heat treatment process? Select the Right Method for Your Metal Components

- What is the holding time for sintering? A Guide to Optimizing Your Process

- What is the function of a high-temperature muffle furnace in synthesizing La-Y-NbO4? Master Solid-Phase Diffusion

- What temperature is conventional sintering? Mastering the Key to Dense, Strong Materials

- What role does a high-temperature box-type muffle furnace play in the preparation of ACN? Expert Synthesis Guide