The primary advantages of planetary ball milling are its ability to deliver extremely high impact energy, achieve rapid and significant particle size reduction, and even induce chemical or structural changes in materials. This makes it far more than a simple grinding tool; it is a versatile instrument for advanced materials processing, including the synthesis of novel alloys and compounds.

The core advantage of a planetary ball mill lies in its unique kinematics. The counter-rotation of the grinding jars against a central sun wheel generates powerful forces that create high-energy impacts, enabling materials processing capabilities that are impossible with conventional milling techniques.

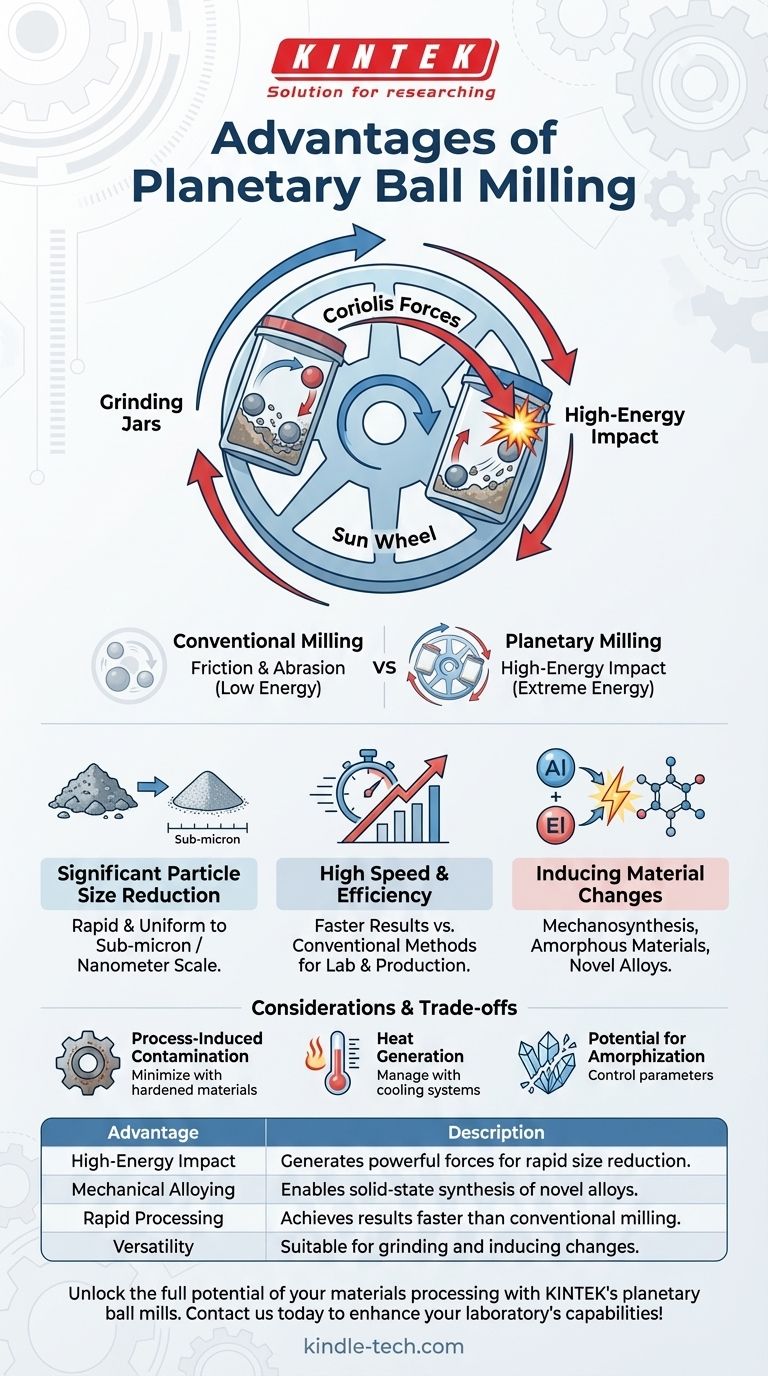

How Planetary Motion Generates Extreme Energy

To understand the advantages of a planetary ball mill, we must first understand its fundamental mechanism. The system is designed not just for grinding, but for creating high-velocity collisions.

The Sun Wheel and Jar Interaction

A planetary ball mill features one or more grinding jars mounted eccentrically on a rotating platform, known as a "sun wheel." As the sun wheel turns in one direction, the individual jars are geared to rotate in the opposite direction.

This counter-rotating motion is the key to the mill's effectiveness. It creates a powerful interplay of forces inside the jar.

The Role of Coriolis Forces

The opposing movements generate strong Coriolis forces. These forces cause the grinding balls to detach from the inner wall of the jar and fly freely across its diameter at high speed.

This free-flight path allows the balls to collide with the material sample with immense kinetic energy.

Impact vs. Friction Energy

In simpler mills, grinding occurs primarily through friction and abrasion as balls tumble over each other. In a planetary mill, the dominant force is high-energy impact.

This impact energy is orders of magnitude greater, leading to faster and more profound effects on the material being processed.

Key Advantages Explained

The high energy generated by the planetary motion translates directly into several key operational advantages.

Significant Particle Size Reduction

The intense impact energy is extremely effective at fracturing materials, allowing for rapid and uniform particle size reduction down to the sub-micron or even nanometer scale.

High Speed and Efficiency

Compared to conventional tumbling or vibratory mills, planetary mills can achieve the same results in a fraction of the time. This makes them highly efficient for both research and production environments.

Inducing Material Changes

The energy imparted to the sample is often high enough to break chemical bonds and create significant crystal defects. While sometimes a side effect, this can be leveraged as a primary advantage.

This process, known as mechanosynthesis or mechanical alloying, can create amorphous (non-crystalline) materials, form new alloys from elemental powders, or trigger solid-state chemical reactions.

Understanding the Trade-offs and Considerations

The high-energy nature of planetary milling also introduces critical factors that must be managed.

Process-Induced Contamination

The powerful impacts can cause wear on the grinding jars and balls. This can introduce trace amounts of the grinding media material into your sample.

Choosing appropriate, hardened materials for the jars and balls (like tungsten carbide, silicon nitride, or zirconia) is essential for minimizing contamination.

Heat Generation

The process generates significant heat due to the intense energy transfer. This can be detrimental to temperature-sensitive materials.

Many planetary mill systems can be equipped with cooling jackets or programmed with pause cycles to help manage the temperature during operation.

Potential for Amorphization

The same energy that enables mechanical alloying can also destroy the crystalline structure of a material when it is not desired.

If preserving a material's original crystal structure is the primary goal, the milling parameters (speed, time, ball-to-powder ratio) must be carefully controlled, or a lower-energy milling method may be more appropriate.

Making the Right Choice for Your Goal

Selecting the right milling technique depends entirely on your end goal. Planetary ball milling is a powerful tool when its specific characteristics align with your objectives.

- If your primary focus is creating novel alloys or amorphous phases: Planetary ball milling is the ideal choice due to its unique ability to induce solid-state reactions through high-energy impacts.

- If your primary focus is rapid particle size reduction to the sub-micron level: The speed and efficiency of a planetary mill make it superior to nearly all other laboratory-scale milling techniques.

- If your primary focus is to maintain a pristine crystal structure with zero contamination: You must carefully control the energy input or consider a lower-impact method, as the aggressiveness of planetary milling can be a disadvantage.

Ultimately, understanding the unique energy dynamics of a planetary ball mill allows you to leverage it as a powerful tool for both material reduction and advanced synthesis.

Summary Table:

| Advantage | Description |

|---|---|

| High-Energy Impact | Generates powerful forces for rapid particle size reduction. |

| Mechanical Alloying | Enables solid-state synthesis of novel alloys and compounds. |

| Rapid Processing | Achieves results faster than conventional milling methods. |

| Versatility | Suitable for both grinding and inducing material changes. |

Unlock the full potential of your materials processing with KINTEK's planetary ball mills.

Our high-performance mills are engineered to deliver the precise, high-energy impacts needed for advanced applications like nanoparticle synthesis and mechanical alloying. Whether you're in R&D or production, KINTEK provides the reliable lab equipment and consumables to meet your specific needs.

Contact us today to discuss how a KINTEK planetary ball mill can enhance your laboratory's capabilities and efficiency!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the role of high-energy ball milling in ODS steel preparation? Unlock Superior Material Strength

- What is the primary function of high-energy ball milling equipment? Unlock Nano-Scale Tungsten Alloy Synthesis

- How does an industrial-grade ball mill affect biochar adsorption? Maximize Surface Area for Water Treatment Efficiency

- What is the role of a high-energy ball mill in the mechanical alloying of Si/Al-doped Fe-Cr ODS steel powders?

- What technical problem do planetary ball mills solve? Optimizing LiFePO4 and LLZTO for Superior Battery Performance

- Why use tungsten carbide for cerium dioxide synthesis? Ensure Purity in Planetary Ball Milling

- How does a planetary ball mill enhance cellulose-graphene compatibility? Unlock High-Performance Composite Synthesis

- How does a Planetary Ball Mill contribute to the mechanochemical dechlorination of PVC? Efficient Waste Treatment