The single greatest advantage of plasma-enhanced chemical vapor deposition (PECVD) is its ability to operate at significantly lower temperatures than conventional thermal CVD methods. While standard CVD relies solely on high heat to drive chemical reactions, PECVD uses an energized plasma to achieve the same result. This fundamental difference dramatically expands the range of materials that can be successfully coated.

While conventional CVD is a powerful tool for creating pure, uniform coatings, its high-temperature requirements limit its use. PECVD overcomes this by using an energy-rich plasma, unlocking the ability to deposit high-quality films on temperature-sensitive materials without causing damage.

The Core Advantage: Lowering the Temperature Barrier

The primary reason to choose PECVD over other methods is its low-temperature operation. This capability stems directly from how it initiates the deposition process.

How Conventional CVD Works (The Heat Problem)

Standard thermal CVD processes require high temperatures, often several hundred to over a thousand degrees Celsius. This thermal energy is necessary to break down the chemical bonds in the precursor gases, allowing the atoms to react and deposit onto the substrate surface as a thin film.

The PECVD Solution: Using Plasma Instead of Heat

PECVD replaces the need for extreme heat with energy from a plasma. An electrical field, typically radio frequency (RF) or direct current (DC), is applied to the precursor gas, stripping electrons from atoms and creating a highly reactive environment of ions and radicals.

This energized plasma provides the necessary energy to break chemical bonds and drive the deposition reaction at a much lower substrate temperature.

Impact on Material Compatibility

This lower operating temperature is the critical benefit. It allows for the deposition of durable, high-quality films onto substrates that would otherwise melt, warp, or be functionally destroyed by the heat of a conventional CVD process.

This makes PECVD essential for applications involving polymers, plastics, pre-fabricated electronic circuits, and other temperature-sensitive components.

Inherited Benefits from Conventional CVD

While its low-temperature operation is its defining feature, PECVD also retains the powerful foundational advantages of the broader CVD family of techniques.

High Purity and Uniformity

Like thermal CVD, PECVD is capable of producing films of exceptionally high purity. The process is also non-line-of-sight, meaning it can create a uniform, conformal coating over parts with complex shapes and intricate surfaces.

Versatility and Control

The process is highly versatile and can be used to deposit a wide range of materials, including ceramics and insulators like silicon carbide (SiC). Technicians have full control over process parameters, allowing for the precise creation of ultra-thin layers essential for modern electronics.

Strong Adhesion and Durability

PECVD films typically form durable coatings that adhere very well to the substrate. These coatings can be engineered to provide resistance to abrasion, corrosion, and extreme temperature variations.

Understanding the Trade-offs

No technology is without its compromises. While powerful, PECVD introduces complexities that are not present in simpler thermal systems.

System Complexity and Cost

A PECVD system is inherently more complex than a thermal CVD furnace. It requires a vacuum chamber, gas delivery systems, and, most critically, a power source (like an RF generator) and associated hardware to create and sustain the plasma. This increases both the initial equipment cost and maintenance overhead.

Potential for Plasma-Induced Damage

The high-energy ions within the plasma can, in some cases, physically bombard the substrate or the growing film. This can induce stress or create microscopic defects, which must be carefully managed by fine-tuning the plasma conditions.

Different Film Properties

Because the deposition occurs at lower temperatures and in a plasma environment, the resulting film's properties can differ from one grown with thermal CVD. For instance, PECVD films may have a different density or chemical composition (e.g., higher hydrogen content), which can be an advantage or a disadvantage depending on the application.

How to Apply This to Your Project

Choosing between PECVD and conventional CVD requires a clear understanding of your project's primary constraint: the substrate's thermal tolerance.

- If your primary focus is coating heat-sensitive substrates: PECVD is the definitive and often only viable choice to prevent thermal damage to materials like plastics or complete electronic devices.

- If your primary focus is achieving specific film properties: You must evaluate both methods, as the "best" film density or purity for a given material may be achieved at either high or low temperatures.

- If your primary focus is minimizing equipment cost for a simple material: Conventional thermal CVD is the more cost-effective solution, provided your substrate can easily withstand the high processing temperatures.

Understanding this fundamental temperature-property trade-off is the key to selecting the right deposition technology for your specific application.

Summary Table:

| Key Advantage | Description |

|---|---|

| Low-Temperature Operation | Deposits films at significantly lower temperatures than conventional CVD, preventing damage to sensitive substrates. |

| High Purity & Uniformity | Produces exceptionally pure, conformal coatings even on complex shapes. |

| Material Versatility | Capable of depositing a wide range of materials, including ceramics and insulators like silicon carbide (SiC). |

| Strong Adhesion | Creates durable, well-adhered coatings resistant to abrasion and corrosion. |

Need to deposit high-quality thin films on temperature-sensitive materials? KINTEK specializes in providing advanced lab equipment and consumables, including PECVD systems, to meet your specific laboratory needs. Our expertise ensures you get the right solution for coating polymers, plastics, and electronic components without thermal damage. Contact us today to discuss how PECVD can enhance your research or production process!

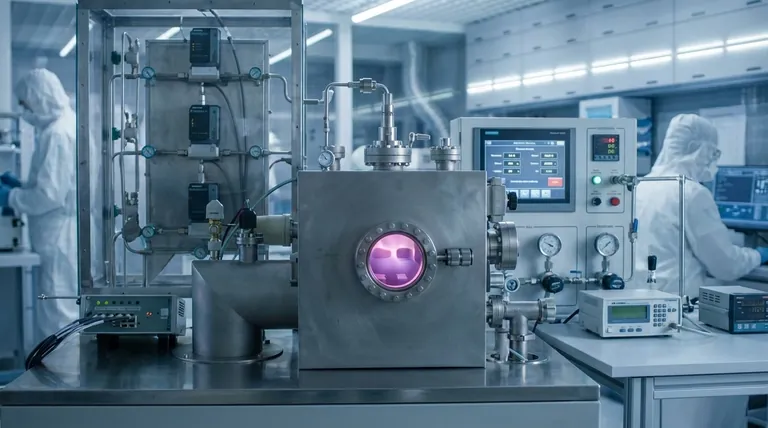

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is plasma enhanced chemical Vapour deposition process used for fabrication of? A Guide to Low-Temperature Thin Films

- How does radio frequency (RF) power affect the PECVD process? Master Ionization for Superior Thin Film Quality

- How strong is DLC coating? Discover the Ultimate Shield for Wear and Friction

- What are the advantages of using PECVD for neural probes? Superior Insulation at Low Temperatures

- What is the plasma generation in PECVD? The Core Technology for Low-Temperature Thin Films

- How are film properties controlled using ICPCVD? Master Precise Atomic Bonding & High-Density Plasma Deposition

- What are the technical advantages of using PECVD for nitrogen-doped cobalt catalysts? Enhance OER Reaction Kinetics

- What is the purpose of PECVD? Achieve Low-Temperature Thin Film Deposition for Sensitive Materials