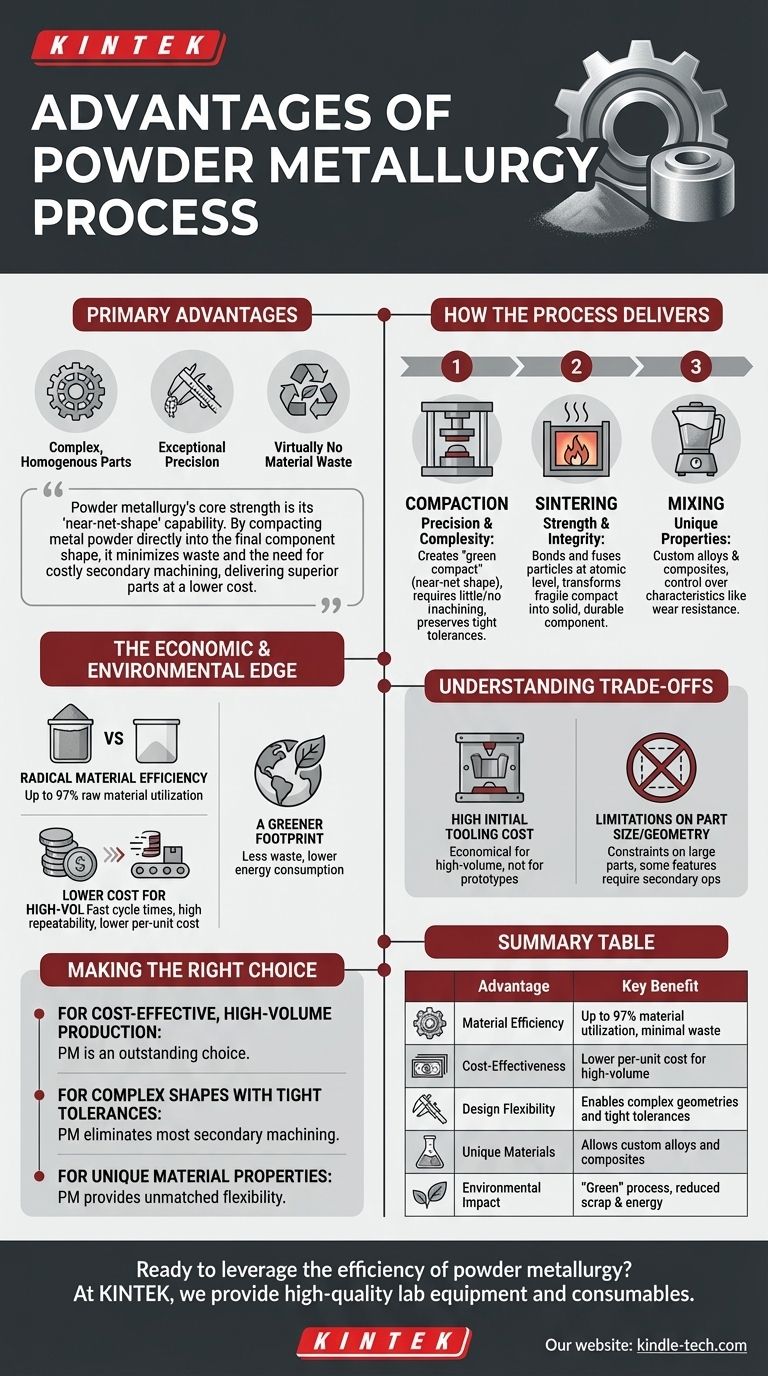

The primary advantages of the powder metallurgy process are its ability to produce complex, homogenous parts with exceptional precision and virtually no material waste. This makes it a highly efficient, cost-effective, and environmentally friendly manufacturing method, especially for high-volume production runs in industries like automotive and aerospace.

Powder metallurgy's core strength is its "near-net-shape" capability. By compacting metal powder directly into the final component shape, it minimizes waste and the need for costly secondary machining, delivering superior parts at a lower cost.

How the Process Delivers Key Advantages

Powder metallurgy (PM) is a multi-step process where each stage contributes directly to the final part's quality and cost-effectiveness. Understanding this flow reveals why it is such a powerful manufacturing technique.

Step 1: Compaction for Precision and Complexity

The first major step involves pressing precisely measured metal powder into a rigid die under extreme pressure. This single action is the source of two of PM's biggest benefits.

It creates a "green compact" that is already in the near-net shape of the final component. This means the part requires little to no follow-up machining, preserving tight tolerances and allowing for complex geometries that would be difficult or expensive to create otherwise.

Step 2: Sintering for Strength and Integrity

The green compact is then heated in a controlled-atmosphere furnace to a temperature just below the metal's melting point. This critical thermal process is called sintering.

During sintering, the individual metal particles bond and fuse together on an atomic level. This process eliminates porosity and transforms the fragile compact into a solid, durable component with the required mechanical strength and hardness.

Step 3: Mixing for Unique Material Properties

Before compaction, different metal powders can be precisely mixed and blended. This allows for the creation of custom alloys and composite materials with unique properties that are often impossible to achieve through traditional melting and casting methods.

This provides engineers with a high degree of control over the final part's characteristics, such as wear resistance, hardness, and conductivity.

The Economic and Environmental Edge

Beyond its technical capabilities, powder metallurgy offers significant financial and ecological benefits that set it apart from other manufacturing processes.

Radical Material Efficiency

The most cited advantage of PM is its minimal waste. Because the process starts with only the amount of powder needed for the part, up to 97% of the raw material becomes part of the finished component.

This stands in stark contrast to subtractive methods like machining, which can generate substantial scrap material that must be collected and recycled.

Lower Cost for High-Volume Production

The combination of high material utilization, fast cycle times, and the elimination of secondary operations makes PM exceptionally cost-effective for large production runs.

Once the initial tooling is created, parts can be produced rapidly and with high repeatability, driving down the per-unit cost significantly.

A Greener Manufacturing Footprint

The dramatic reduction in scrap makes powder metallurgy an inherently environmentally friendly, or "green," process. Less waste means less energy is consumed in raw material production and recycling, contributing to a more sustainable manufacturing cycle.

Understanding the Trade-offs and Limitations

While powerful, powder metallurgy is not the ideal solution for every application. Being aware of its limitations is key to using it effectively.

High Initial Tooling Cost

The primary trade-off is the high upfront cost of the compaction dies. These tools must be made from hardened steel to withstand immense pressures and are expensive to design and fabricate.

This initial investment is why PM is most economical for high-volume production, where the tooling cost can be amortized over tens of thousands of parts. It is generally not suitable for prototypes or low-volume runs.

Limitations on Part Size and Geometry

The compaction process places some constraints on part design. Extremely large parts can be challenging to produce, and certain features like undercuts or threads perpendicular to the pressing direction are not possible without secondary operations.

Advanced Methods for Enhanced Performance

To overcome some limitations, specialized variations of the PM process exist. For example, hot pressing combines compaction and sintering into one step to create denser, stronger parts, such as sintered carbide cutting tools.

Making the Right Choice for Your Goal

Selecting powder metallurgy depends entirely on your project's specific priorities and constraints.

- If your primary focus is cost-effective, high-volume production: PM is an outstanding choice due to its high speed, repeatability, and minimal material waste.

- If your primary focus is creating complex shapes with tight tolerances: The near-net-shape capability of PM eliminates most secondary machining, delivering precise parts right out of the furnace.

- If your primary focus is developing unique material properties: PM provides unmatched flexibility to create custom alloys and composites tailored to your exact performance needs.

Ultimately, choosing powder metallurgy allows you to manufacture superior components with an exceptional degree of efficiency and control.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Efficiency | Up to 97% material utilization, minimal waste |

| Cost-Effectiveness | Lower per-unit cost for high-volume production |

| Design Flexibility | Enables complex geometries and tight tolerances |

| Unique Materials | Allows creation of custom alloys and composites |

| Environmental Impact | "Green" process due to reduced scrap and energy use |

Ready to leverage the efficiency of powder metallurgy for your components?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed to support advanced manufacturing processes like powder metallurgy. Whether you are in R&D or high-volume production, our solutions can help you achieve superior results with precision and reliability.

Contact our experts today to discuss how we can support your laboratory and manufacturing needs with the right equipment for your powder metallurgy applications.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the drawbacks of sputtering? Balancing High Film Quality with Cost and Speed

- What is the best steel for high temperature applications? Choose the Right Material for Extreme Heat

- What is the alternative process to sintering? Compare Casting, Forging & Machining for Your Project

- What is the application of reactive sputtering? Synthesize High-Performance Compound Films

- What are the pros and cons of hot forging? Unlock Superior Strength for Critical Components

- What role does a constant temperature laboratory oven play in preparing waste eggshell catalysts? Ensure Peak Efficiency

- What does the acronym CVD stand for? Decoding Its Meaning in Medicine and Technology

- What is the difference between thermal and catalytic pyrolysis? Maximize Yield vs. Improve Oil Quality