At its core, powder sintering is a thermal process that dramatically enhances a material's properties by transforming loose powder into a dense, solid object. The primary advantages are significantly increased material strength, improved thermal and electrical conductivity, and in the case of certain ceramics, greater translucency, all achieved without melting the base material.

Sintering’s true value lies in its ability to eliminate the voids, or pores, between powder particles. By fusing the particles together using carefully controlled heat, the process creates a denser, more consolidated material with fundamentally superior physical characteristics.

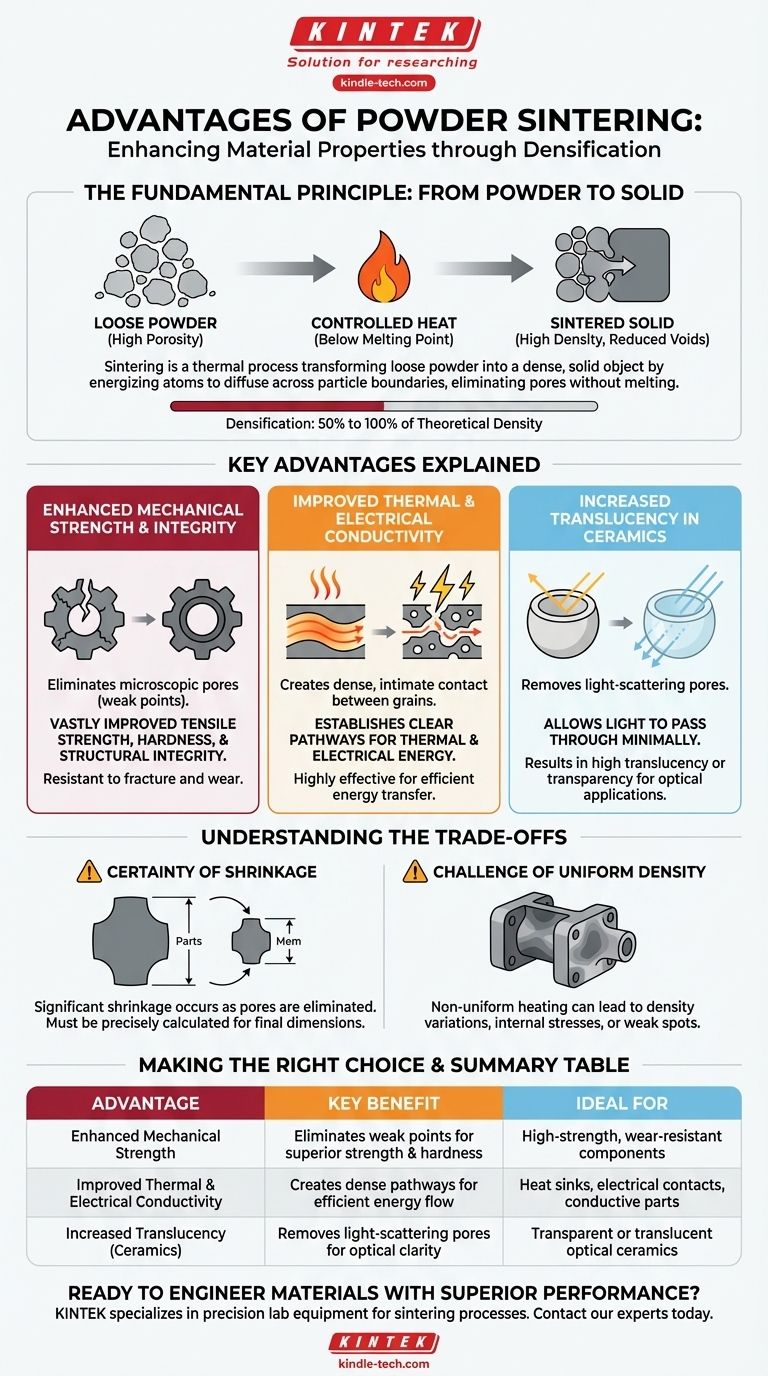

The Fundamental Principle: From Powder to Solid

To understand the advantages of sintering, you must first grasp the mechanism. It's a process of consolidation driven by thermal energy.

The Role of Heat Below Melting

Sintering involves heating a compacted powder component to a high temperature, but one that remains below the material's melting point. This is a critical distinction. The goal isn't to liquefy the material, but to energize its atoms enough to promote bonding.

How Atomic Diffusion Drives Consolidation

At these elevated temperatures, atoms begin to diffuse across the boundaries of adjacent powder particles. This process naturally seeks to reduce the system's total surface energy.

As particles bond and merge, the small voids and pores between them begin to shrink and eventually close up. This migration of matter effectively fills the empty space.

The Primary Result: Increased Density

The direct consequence of eliminating these internal pores is a significant increase in the material's density. A loosely compacted powder might be 50% porous, but a fully sintered part can approach 100% of the material's theoretical density. This densification is the direct source of sintering's many benefits.

Key Advantages Explained

The densification achieved through sintering directly translates into tangible improvements in material performance.

Enhanced Mechanical Strength and Integrity

Pores are microscopic weak points within a material. By eliminating them, sintering removes these potential failure sites. The result is a part with vastly improved tensile strength, hardness, and overall structural integrity. The continuous, bonded microstructure is far more resistant to fracture and wear.

Improved Thermal and Electrical Conductivity

The voids between unsintered particles act as insulators, impeding the flow of heat and electricity. By creating a dense, solid mass with intimate contact between grains, sintering establishes clear pathways for thermal and electrical energy. This makes sintered parts highly effective for applications requiring efficient energy transfer.

Increased Translucency in Ceramics

For optical materials like advanced ceramics, pores are the enemy of clarity. They scatter light, making the material appear opaque. By removing these scattering sites, sintering allows light to pass through the material with minimal obstruction, resulting in high translucency or even transparency.

Understanding the Trade-offs

While powerful, sintering is a precise process with inherent challenges that must be managed.

The Certainty of Shrinkage

As pores are eliminated and the part densifies, it will inevitably shrink. This shrinkage is significant and must be precisely calculated and accounted for during the initial design and powder compaction stages to achieve the correct final dimensions.

The Challenge of Uniform Density

Achieving perfectly uniform heating throughout a complex part can be difficult. Non-uniform temperatures can lead to variations in density, creating internal stresses or weak spots that could compromise the component's performance.

Material and Process Constraints

Sintering is not a universal solution. The process is highly dependent on the material type, particle size, and atmosphere. The temperature window between effective sintering and undesirable melting can be narrow, requiring extremely precise process control.

Making the Right Choice for Your Application

Selecting sintering depends entirely on your end goal. It is a tool for achieving specific microstructural properties that enable high performance.

- If your primary focus is mechanical performance: Sintering is ideal for creating high-strength, wear-resistant parts by maximizing density and eliminating the internal voids that initiate failure.

- If your primary focus is thermal or electrical management: Use sintering to create highly conductive components by removing the insulating effect of porosity and ensuring a continuous material pathway.

- If your primary focus is creating optical components: Sintering is a key process for achieving the near-perfect density required for translucency or transparency in advanced ceramics.

Ultimately, understanding sintering allows you to deliberately engineer a material's internal structure to unlock its maximum performance potential.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Enhanced Mechanical Strength | Eliminates weak points (pores) for superior tensile strength and hardness. | High-strength, wear-resistant components. |

| Improved Thermal & Electrical Conductivity | Creates dense pathways for efficient energy flow. | Heat sinks, electrical contacts, and conductive parts. |

| Increased Translucency (Ceramics) | Removes light-scattering pores for optical clarity. | Transparent or translucent optical ceramics. |

Ready to engineer materials with superior performance? KINTEK specializes in precision lab equipment and consumables for sintering processes, helping laboratories achieve consistent, high-density results. Whether you're developing stronger components, conductive parts, or optical ceramics, our solutions ensure precise temperature control and process reliability. Contact our experts today to discuss how we can support your sintering R&D and production needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations