The primary advantages of a rotary kiln furnace are its ability to achieve exceptional product uniformity, high thermal efficiency, and continuous processing capabilities. By constantly tumbling the material, it ensures every particle is exposed to the same temperature and atmospheric conditions, which is fundamentally more efficient than static batch processing.

In industrial materials processing, inconsistency is a critical failure point. A rotary kiln furnace directly addresses this by combining continuous mixing with precise environmental control, making it a superior choice for achieving uniform, high-quality output at scale.

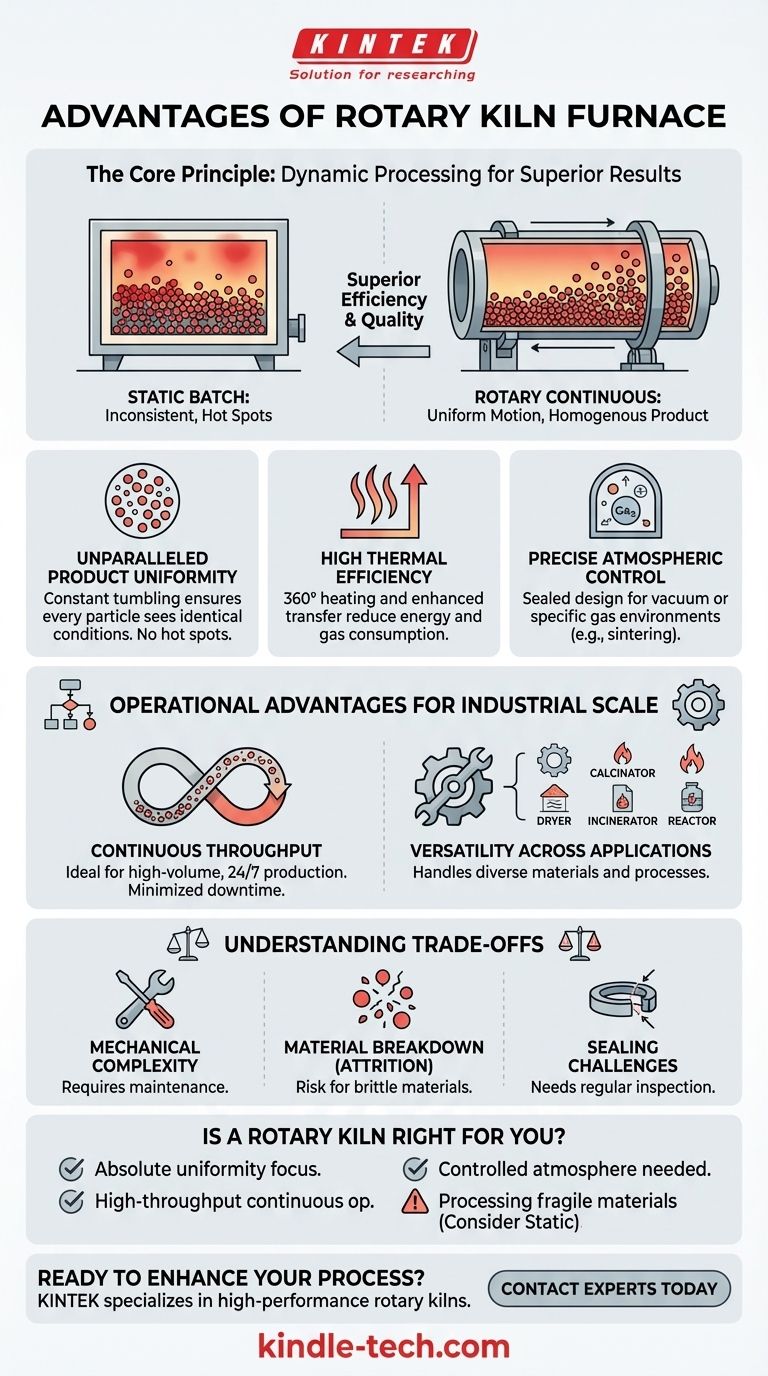

The Core Principle: Dynamic Processing for Superior Results

The defining feature of a rotary kiln is its slow, constant rotation. This simple mechanical action is the source of its most significant advantages over static or box furnaces.

Constant Motion Creates Unparalleled Uniformity

In a static furnace, material at the edges of a container heats faster than material in the center, creating inconsistencies. A rotary kiln solves this by continuously tumbling the contents.

This motion ensures that every particle is uniformly exposed to the heat source and the controlled atmosphere inside the furnace. The result is a highly homogenous final product, free from the hot spots and under-processed sections common in batch systems.

Enhanced Heat and Gas Transfer

The tumbling action constantly exposes the entire surface area of the material being processed. This dramatically improves the efficiency of both heat transfer and gas diffusion.

Because the heat and process gases can interact with the material so effectively, the system requires less energy and less gas consumption to achieve the desired result, increasing overall operational efficiency.

Precise Atmospheric Control

Rotary kilns are designed as sealed systems, allowing for meticulous control over the internal environment.

The furnace chamber can be evacuated to create a vacuum or filled with a specific gas, such as a reducing or inert atmosphere. This is critical for high-temperature processes like sintering, where preventing oxidation or inducing a specific chemical reaction is essential.

Operational Advantages for Industrial Scale

Beyond the quality of the final product, the design of a rotary kiln offers key benefits for large-scale industrial operations.

Continuous, Uninterrupted Throughput

Unlike a batch furnace that must be loaded, heated, cooled, and unloaded in sequence, a rotary kiln can operate continuously.

Material is fed into the elevated end of the tilted cylinder and slowly moves to the discharge end as it rotates. This design is ideal for high-volume production, reducing downtime and minimizing manual material handling.

High Thermal Efficiency

Modern rotary kilns are highly engineered for energy efficiency. Features like 360° heater placement ensure that heat is transmitted evenly and effectively into the material load.

The kiln itself also acts as a heat exchanger, using the hot material and gases to pre-heat incoming material, further optimizing energy use.

Versatility Across Applications

The rotary kiln is not a one-trick pony. Its ability to heat, mix, and control atmosphere makes it suitable for a wide range of thermal processes.

It can function as a dryer, calcinator, incinerator, and chemical reactor, handling diverse solid materials from fine powders to larger granules across numerous industries.

Understanding the Trade-offs

While powerful, the rotary kiln is not a universal solution. Its advantages come with specific considerations.

Mechanical Complexity and Maintenance

The drive system, rotational seals, and support structures that enable the kiln's core function are more complex than a static furnace. This can translate to higher initial investment and a more involved preventative maintenance schedule.

Potential for Material Breakdown

The tumbling action that creates uniformity can be detrimental to brittle or friable materials. This mechanical stress, known as attrition, can cause particles to break down, which may be undesirable for certain products.

Sealing Challenges

Maintaining a perfect, airtight seal on a large, rotating piece of equipment operating at extremely high temperatures is a significant engineering challenge. While modern seals are highly effective, they are critical wear components that require regular inspection and replacement to ensure atmospheric integrity.

Is a Rotary Kiln Right for Your Process?

Choosing the right thermal processing equipment depends entirely on your primary goal.

- If your primary focus is absolute product uniformity: The continuous mixing of a rotary kiln is unparalleled for eliminating inconsistencies and ensuring every particle is processed identically.

- If your primary focus is high-throughput continuous operation: Its ability to process material without stops makes it the clear choice for large-scale, 24/7 industrial production.

- If your primary focus is running reactions in a controlled atmosphere: The sealed design is ideal for processes that require specific gas environments or must avoid contamination from ambient air.

- If your primary focus is processing fragile or brittle materials: You must carefully evaluate the risk of attrition and may need to consider a static furnace to preserve material integrity.

Ultimately, the rotary kiln is a powerful and efficient tool designed to produce a highly consistent product at an industrial scale.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Product Uniformity | Continuous tumbling ensures every particle is uniformly processed. |

| Thermal Efficiency | 360° heating and efficient heat transfer reduce energy consumption. |

| Continuous Processing | Enables high-volume, 24/7 operation without batch downtime. |

| Atmospheric Control | Sealed design allows for precise vacuum or gas environments. |

| Versatility | Suitable for drying, calcining, sintering, and chemical reactions. |

Ready to enhance your material processing with superior uniformity and efficiency?

KINTEK specializes in high-performance rotary kiln furnaces and other advanced lab equipment, designed to meet the rigorous demands of industrial-scale production. Our solutions deliver the precise temperature control, consistent results, and operational reliability your laboratory needs.

Contact our experts today to discuss how a KINTEK rotary kiln can optimize your process and achieve your quality and throughput goals.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing