At its core, sintering is the fundamental process that transforms a compacted mass of ceramic powder into a strong, dense, and functional solid component. It is the critical manufacturing step where the material acquires its most important properties, including high mechanical strength, hardness, and thermal stability. Without sintering, most advanced ceramic products would simply not exist.

The primary advantage of sintering is not just an improvement but a complete transformation. It converts a fragile collection of individual particles into a unified, densified object with a precisely controlled internal structure, unlocking the high-performance characteristics inherent in the ceramic material.

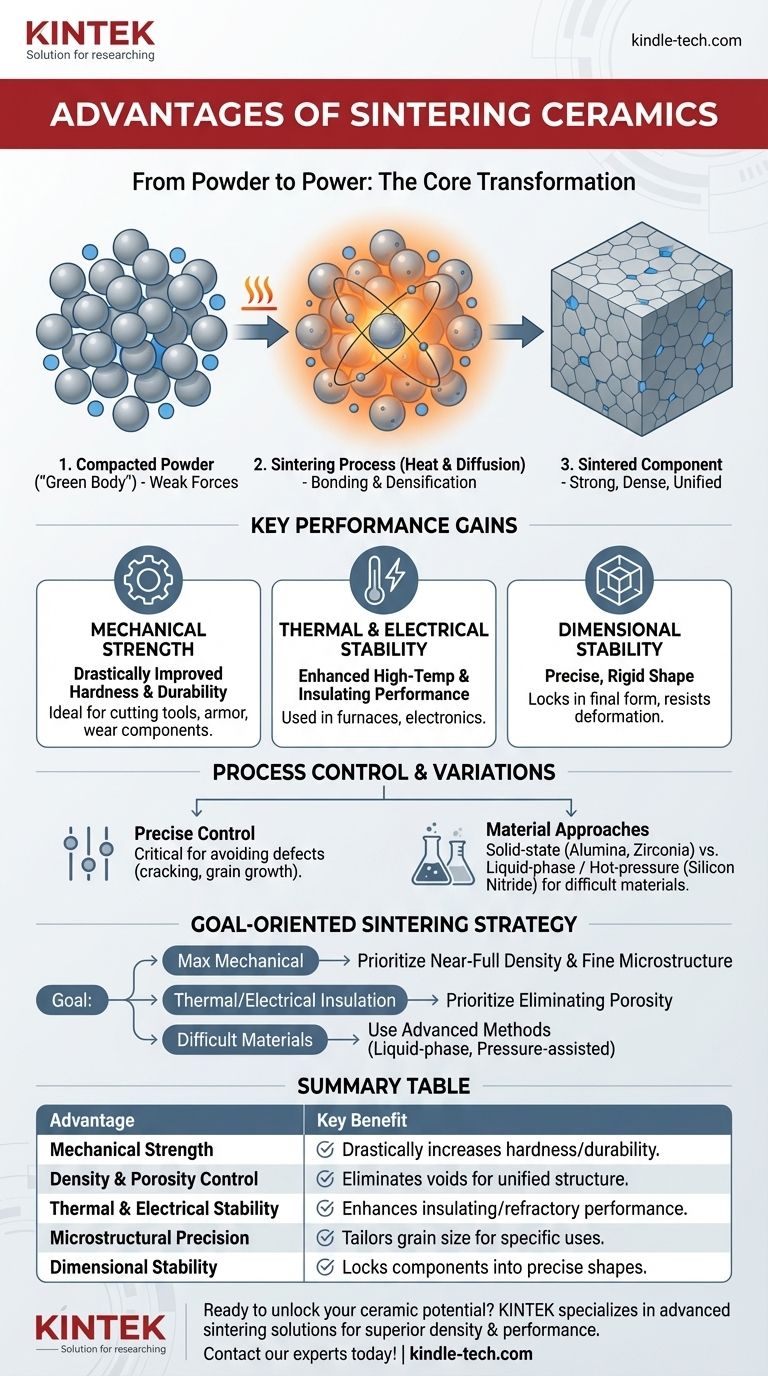

From Powder to Power: The Core Transformation

Sintering is the thermal treatment that bonds ceramic particles together, fundamentally changing the nature of the material. This process is what turns a shaped, but weak, "green body" into a durable, finished part.

Creating a Strong, Unified Structure

Before sintering, a ceramic part is just compacted powder held together by weak forces. During sintering, atoms diffuse across the boundaries of the particles, causing them to fuse together and form strong chemical bonds. This creates a continuous, polycrystalline solid structure.

Achieving High Density and Low Porosity

The primary goal of sintering is densification. The process eliminates the pores and voids between the initial powder particles, drastically increasing the material's density. This reduction in porosity is directly responsible for the massive gains in strength and durability.

Controlling the Final Microstructure

Sintering allows for precise control over the final microstructure—the size and arrangement of the grains within the ceramic. By carefully managing sintering parameters like temperature, time, and atmosphere, manufacturers can tailor the material's properties for specific applications, such as ultra-hard cutting tools or highly effective electrical insulators.

The Tangible Performance Gains

The microstructural changes that occur during sintering translate directly into superior real-world performance characteristics. These advantages are why sintering is indispensable in ceramic manufacturing.

Drastically Improved Mechanical Strength

A sintered ceramic is orders of magnitude stronger and harder than its unsintered powder form. This high strength and resistance to wear make sintered ceramics ideal for demanding applications like industrial cutting tools, armor, and wear-resistant components.

Enhanced Thermal and Electrical Stability

The dense, unified structure created by sintering gives ceramics excellent stability at high temperatures and makes them superb electrical insulators. This is why they are essential for refractory materials used in furnaces and as insulating components in electronic devices.

Achieving a Stable, Precise Shape

Sintering locks the component into its final, stable geometric form. While some predictable shrinkage occurs, the process yields a rigid part with excellent dimensional stability that will not deform under operational stress.

Understanding the Trade-offs and Process Variations

While immensely beneficial, sintering is a complex process that demands precision. The chosen method depends entirely on the material and the desired outcome, each with its own set of considerations.

The Need for Precise Control

The benefits of sintering are only realized when the process is carefully controlled. Incorrect temperatures or timing can lead to incomplete densification, exaggerated grain growth, or internal cracking, all of which degrade the final properties of the ceramic.

Material-Specific Approaches

Different ceramics require different sintering strategies.

- Solid-state sintering, driven by atomic diffusion, works well for materials like alumina and zirconia.

- Liquid-phase sintering is used for harder-to-sinter materials like silicon nitride. It involves an additive that melts, creating a liquid that helps rearrange and bond the solid particles more effectively through capillary forces.

The Cost of Advanced Techniques

For the most demanding applications, advanced methods like hot-pressure sintering are used. This technique applies external pressure during heating, which accelerates densification and helps produce superior properties. However, this adds significant complexity and cost to the manufacturing process.

Making the Right Choice for Your Goal

The "best" sintering approach is defined by the end-use application of the ceramic component. Your objective determines the required properties, which in turn dictates the process.

- If your primary focus is maximum mechanical performance: You must prioritize achieving near-full density and a fine, uniform microstructure through precisely controlled sintering parameters.

- If your primary focus is thermal or electrical insulation: Your goal is to use sintering to eliminate porosity, as voids can compromise insulating capability and create weak points.

- If you are working with difficult-to-densify materials: You must explore advanced methods like liquid-phase or pressure-assisted sintering to overcome the material's inherent resistance to densification.

Ultimately, mastering sintering is mastering the ability to engineer the internal structure of a ceramic to achieve its full performance potential.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Mechanical Strength | Drastically increases hardness and durability for demanding applications. |

| Density & Porosity Control | Eliminates voids, creating a dense, unified structure. |

| Thermal & Electrical Stability | Enhances performance as insulators and refractory materials. |

| Microstructural Precision | Tailors grain size and arrangement for specific uses. |

| Dimensional Stability | Locks components into precise, stable shapes. |

Ready to unlock the full potential of your ceramic components? KINTEK specializes in advanced lab equipment and consumables for precise sintering processes. Whether you're developing cutting tools, insulators, or refractory materials, our solutions help you achieve superior density, strength, and performance. Contact our experts today to optimize your sintering strategy and elevate your lab's capabilities!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects