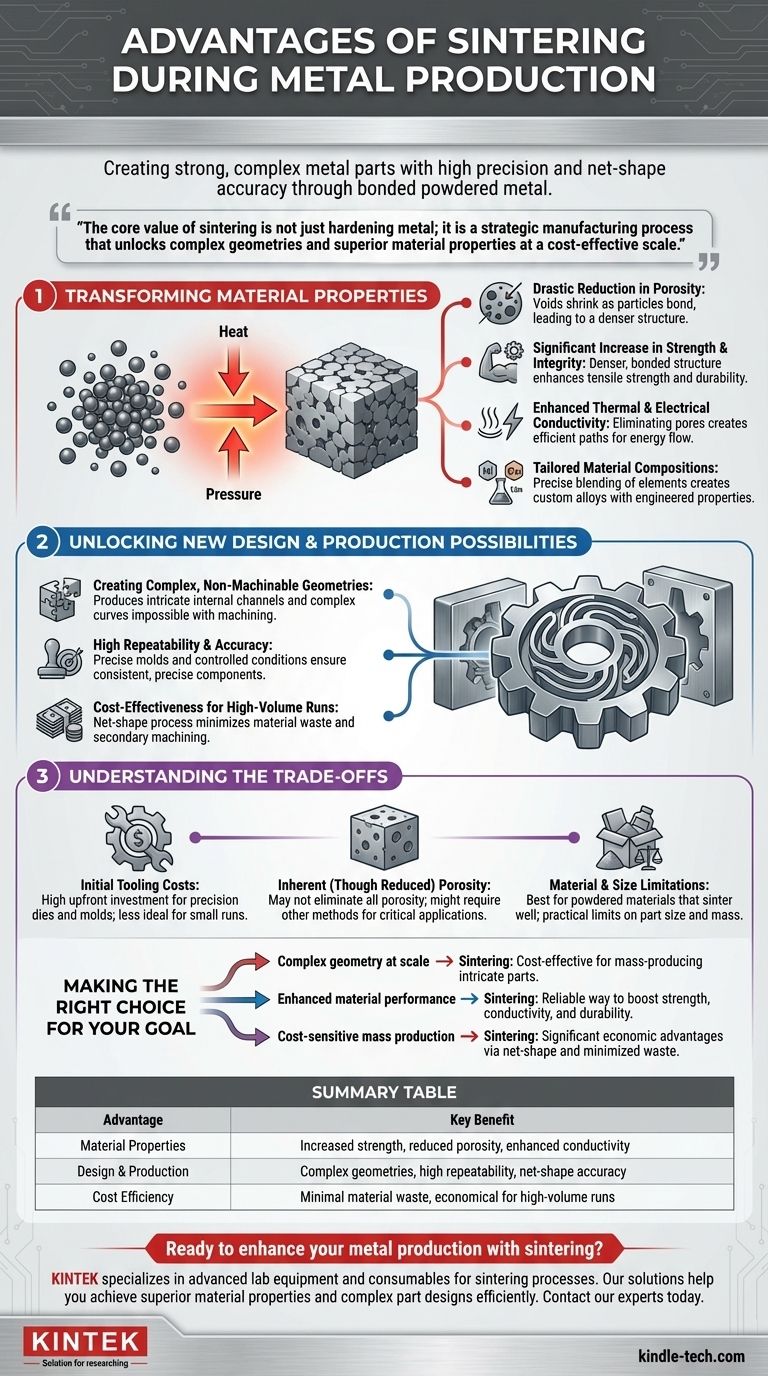

Sintering's primary advantage is its ability to create strong, complex metal parts with high precision and net-shape accuracy. By applying heat below the material's melting point, this process bonds powdered metal particles into a solid, dense mass. This fundamentally enhances material properties like strength and conductivity while enabling the mass production of intricate designs that would be difficult or impossible to achieve with traditional methods.

The core value of sintering is not just hardening metal; it is a strategic manufacturing process that unlocks complex geometries and superior material properties at a cost-effective scale, often surpassing the capabilities of casting or forging.

How Sintering Fundamentally Transforms Material Properties

Sintering is a transformative process that re-engineers a material's internal structure. The primary goal is to take a compacted powder and turn it into a solid, high-performance component.

Drastic Reduction in Porosity

The most critical change during sintering is the reduction of voids, or pores, between the initial powder particles. As the particles bond and form "sintered necks," these empty spaces shrink significantly.

This densification is the root cause of nearly all other property improvements.

Significant Increase in Strength and Integrity

A less porous part is inherently stronger. By creating a solid, bonded structure, sintering dramatically increases the material's tensile strength and overall durability.

This allows sintered parts to withstand higher mechanical stresses in demanding applications.

Enhanced Thermal and Electrical Conductivity

Pores act as insulators, impeding the flow of heat and electricity. By eliminating these voids, sintering creates a more direct and efficient path for energy transfer.

This results in finished parts with superior thermal and electrical conductivity compared to their pre-sintered state.

Tailored Material Compositions

Sintering allows for the precise blending of different elements in powdered form, such as nickel, copper, or graphite. During heating, these elements diffuse, creating custom alloys with specifically engineered properties that would be difficult to achieve through melting.

Unlocking New Possibilities in Design and Production

Beyond improving the material itself, sintering provides significant advantages from a manufacturing perspective, enabling new levels of design freedom and production efficiency.

Creating Complex, Non-Machinable Geometries

This is a key advantage over traditional manufacturing. Sintering can produce parts with intricate internal channels, complex curves, and other features that are prohibitively expensive or physically impossible to create with machining.

High Repeatability and Accuracy

The process uses precise molds and tightly controlled conditions, resulting in components that are remarkably consistent from one to the next.

This high degree of repeatability is essential for mass production where tight tolerances are required.

Cost-Effectiveness for High-Volume Runs

Sintering is a "net-shape" or "near-net-shape" process, meaning the part comes out of the mold very close to its final dimensions.

This minimizes material waste and the need for costly secondary finishing or machining steps, making it highly economical for large production volumes.

Understanding the Trade-offs

No process is perfect, and choosing sintering requires an understanding of its limitations. Being aware of these factors ensures it is applied to the right problems.

Initial Tooling Costs

Creating the high-precision dies and molds required for the initial powder compaction can be a significant upfront investment.

This makes sintering less cost-effective for very small production runs or one-off prototypes.

Inherent (Though Reduced) Porosity

While sintering drastically reduces porosity, it may not eliminate it completely.

For critical applications requiring absolute, 100% density—such as those in high-pressure or vacuum systems—other methods like forging may be necessary.

Material and Size Limitations

The process is best suited for materials available in powdered form that sinter well. Furthermore, there are practical limits on the size and overall mass of parts that can be effectively and evenly sintered.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your project's specific priorities. Sintering excels in several key areas.

- If your primary focus is complex geometry at scale: Sintering is often the most cost-effective method for mass-producing intricate parts that are difficult to machine.

- If your primary focus is enhanced material performance: Sintering provides a reliable way to boost strength, conductivity, and durability by creating a denser, more unified material structure.

- If your primary focus is cost-sensitive mass production: Sintering's ability to produce net-shape parts minimizes waste and secondary processing, offering significant economic advantages for large volumes.

Ultimately, choosing sintering is a strategic decision to gain design freedom and material integrity within a highly repeatable and economical production framework.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Properties | Increased strength, reduced porosity, enhanced thermal/electrical conductivity |

| Design & Production | Complex geometries, high repeatability, net-shape accuracy |

| Cost Efficiency | Minimal material waste, economical for high-volume runs |

Ready to enhance your metal production with sintering? KINTEK specializes in advanced lab equipment and consumables for sintering processes. Our solutions help you achieve superior material properties and complex part designs efficiently. Contact our experts today to discuss how we can support your laboratory's sintering needs and drive your production forward.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What technical functions does a vacuum hot pressing sintering furnace provide? Optimize CoCrFeNi Alloy Coatings

- What temperature does tungsten carbide sinter at? Master the 1350°C-1500°C Liquid-Phase Sintering Process

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.