In short, solid-state sintering provides a powerful method for enhancing material properties and enabling efficient manufacturing. It allows for the creation of strong, dense parts from powdered materials by heating them below their melting point, which improves characteristics like strength and conductivity, enables the production of complex shapes at a low cost, and makes it possible to work with materials that have extremely high melting points.

The fundamental advantage of solid-state sintering is its ability to create dense, high-performance parts from powdered material at temperatures below the melting point. This unlocks cost-effective mass production of complex components from materials that are otherwise difficult or impossible to process.

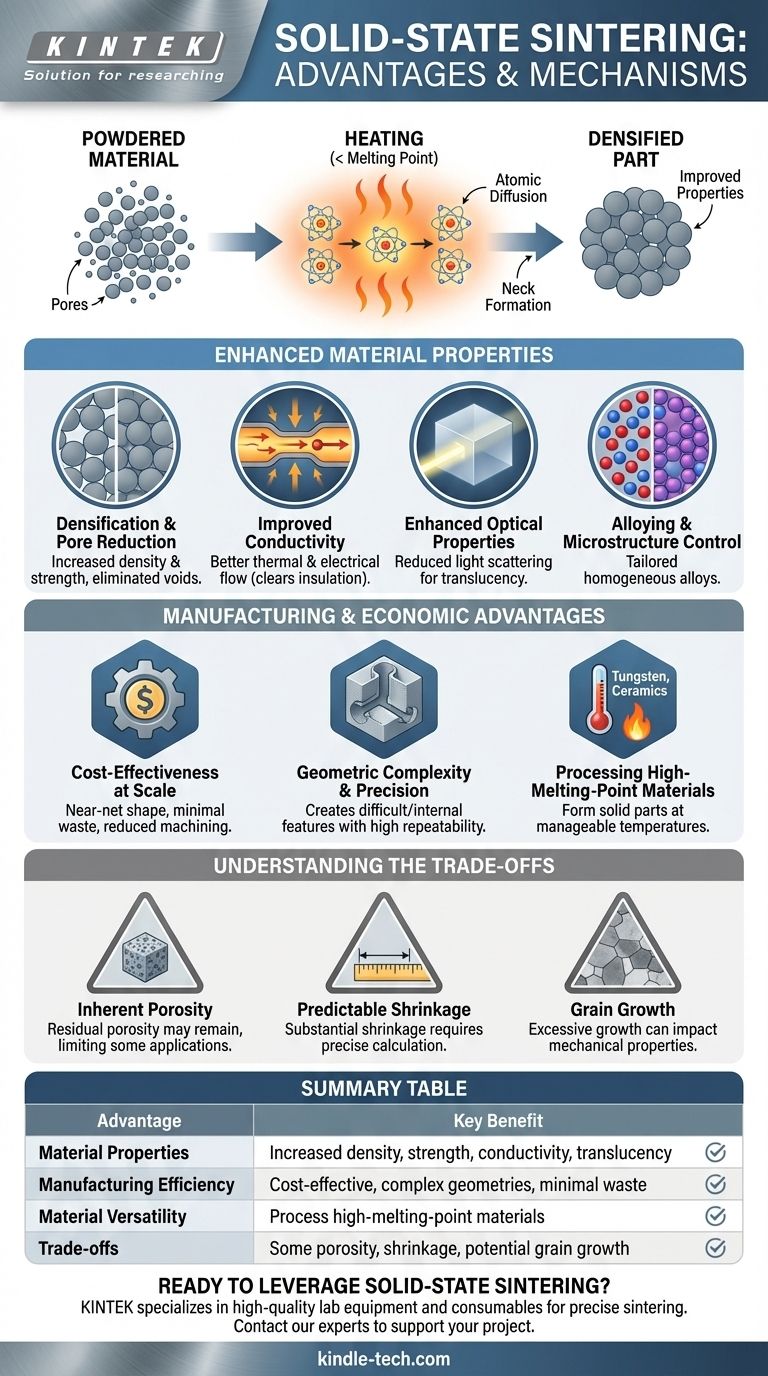

How Sintering Enhances Material Properties

Solid-state sintering is not simply about gluing particles together; it is a process of atomic transformation. The high heat, applied below the material's melting point, energizes atoms and causes them to move, fundamentally changing the material's internal structure and its resulting properties.

Densification and Pore Reduction

The initial powder compact is full of voids or pores. During sintering, atoms diffuse across the boundaries of adjacent particles, forming "necks" that grow over time. This process pulls the particles closer together, systematically eliminating the pores and increasing the overall density of the part, which directly translates to greater strength and integrity.

Improved Thermal and Electrical Conductivity

The pores within an unsintered powder act as insulators, hindering the flow of heat and electricity. By eliminating these voids and creating a continuous solid mass, sintering provides a clear path for electrons and phonons (heat vibrations) to travel, significantly improving both thermal and electrical conductivity.

Enhanced Optical Properties

In ceramic materials, pores scatter light, which results in an opaque appearance. As sintering removes these pores, it reduces internal light scattering. For certain materials, this can lead to a significant increase in translucency or even transparency.

Alloying and Microstructure Control

Sintering is an effective way to create alloys. By mixing powders of different elements (like iron, graphite, nickel, and copper), the diffusion process allows the atoms to intermingle and form a new, homogenous alloy with tailored properties directly within the final part shape.

Key Manufacturing and Economic Advantages

Beyond material science, solid-state sintering offers profound benefits from a production standpoint, making it a competitive choice for a wide range of applications.

Cost-Effectiveness at Scale

Sintering excels at producing parts in a "near-net shape," meaning they come out of the furnace very close to their final dimensions. This dramatically reduces material waste and minimizes the need for costly secondary machining, making it highly cost-effective for medium-to-high volume production runs.

Geometric Complexity and Precision

Molding powder allows for the creation of highly complex geometries—including internal channels, undercuts, and non-machinable features—that would be difficult or impossible to produce with traditional subtractive manufacturing. The process also offers excellent repeatability and good dimensional tolerance control.

Processing High-Melting-Point Materials

This is one of sintering's most critical advantages. Materials like tungsten, molybdenum, and many advanced ceramics have melting points so high that melting and casting them is incredibly energy-intensive and technically challenging. Sintering bypasses this obstacle entirely, enabling the formation of solid parts at much lower, more manageable temperatures.

Understanding the Trade-offs

No process is without limitations. An objective evaluation requires acknowledging the inherent trade-offs of solid-state sintering.

Inherent Porosity

While sintering significantly reduces porosity, achieving 100% theoretical density is difficult and often requires secondary processes like Hot Isostatic Pressing (HIP). Some residual porosity almost always remains, which can be a limiting factor for applications demanding the absolute highest mechanical performance.

Predictable Shrinkage

As pores are eliminated, the component shrinks. This shrinkage is substantial and must be precisely calculated and controlled to achieve tight final tolerances, which adds a layer of complexity to the design and tooling phases.

Grain Growth

The same heat that drives densification can also cause the microscopic grains of the material to grow larger. Excessive grain growth can sometimes negatively impact certain mechanical properties, such as toughness. Process control involves balancing densification against unwanted grain growth.

Applying Sintering to Your Project

Your choice to use sintering should be driven by a clear understanding of your primary goal.

- If your primary focus is cost-effective mass production of complex metal parts: Sintering is an exceptional choice, as it minimizes material waste and the need for secondary machining.

- If your primary focus is processing high-performance materials with very high melting points (like ceramics or refractory metals): Solid-state sintering is often the most practical and energy-efficient method available.

- If your primary focus is achieving the absolute maximum fatigue life or strength for a critical component: You may need to pair sintering with a secondary densification process or evaluate alternative methods like forging or machining from billet.

By understanding its core mechanism of atomic diffusion, you can effectively leverage solid-state sintering to create high-value components that balance performance, complexity, and cost.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Properties | Increased density, strength, thermal/electrical conductivity, and translucency. |

| Manufacturing Efficiency | Cost-effective mass production, complex geometries, minimal material waste. |

| Material Versatility | Enables processing of high-melting-point materials like tungsten and ceramics. |

| Trade-offs | Some inherent porosity, predictable shrinkage, potential for grain growth. |

Ready to leverage solid-state sintering for your laboratory's material processing needs?

KINTEK specializes in providing the high-quality lab equipment and consumables necessary for precise sintering processes. Whether you are developing advanced ceramics, refractory metals, or complex metal parts, our solutions can help you achieve superior material properties and manufacturing efficiency.

Contact our experts today to discuss how we can support your project with reliable equipment and tailored consumables.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why do we use KBr in FTIR? The Key to Clear, Accurate Solid Sample Analysis

- What are the technical requirements for vacuum chambers in desalination? Boost Efficiency with Graphene Technology

- What is the easiest to melt metal? Start with Tin and Pewter for Safe, Simple Casting

- What is the name of rotavap? Discover the Precision of Rotary Evaporators

- What can sintering affect? Transform Powder into High-Performance Solid Parts

- How do you test for CVD diamonds? Uncover the scientific methods for definitive identification.

- What is the effect of pressure on sputtering? Control Film Density and Quality

- How does a rotary vacuum evaporator work? A Guide to Gentle, Efficient Solvent Removal