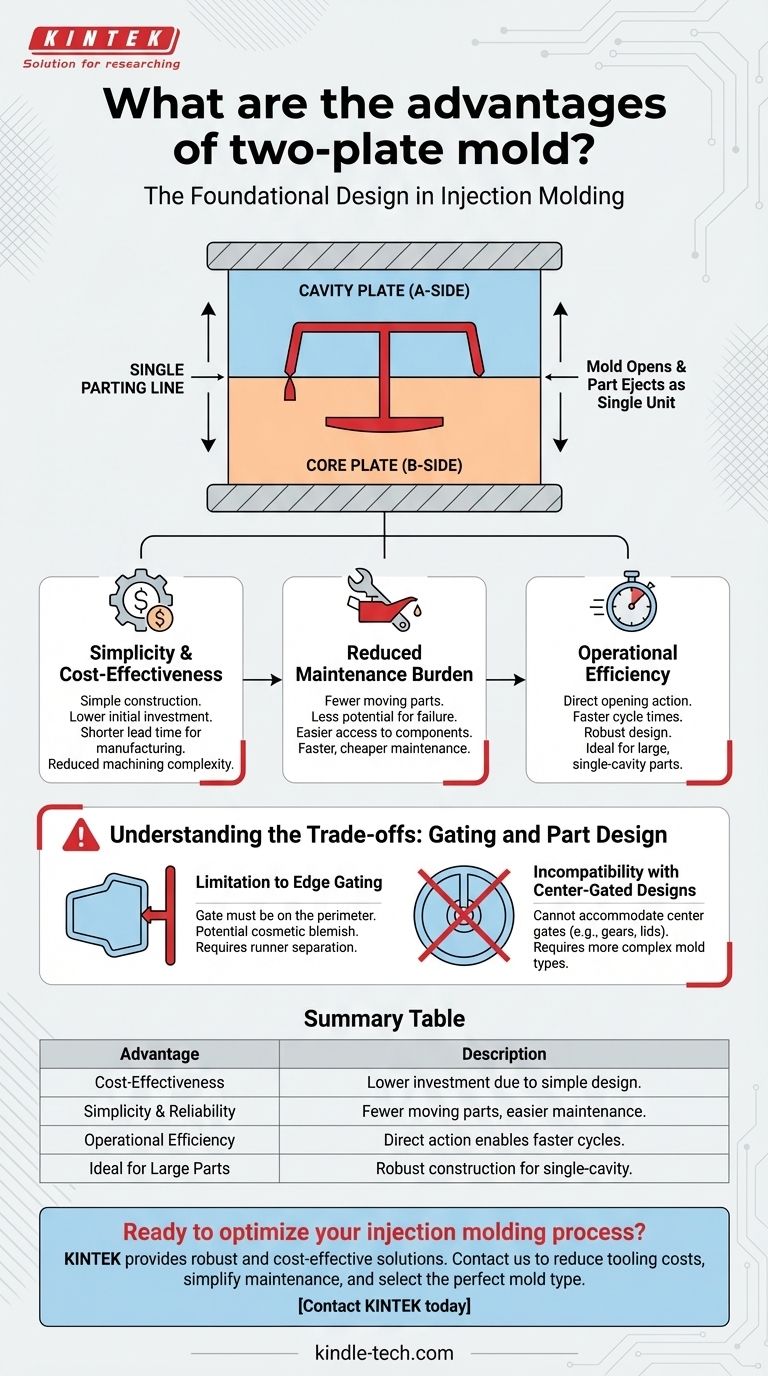

When evaluating injection molding tooling, the two-plate mold represents the foundational design, and its primary advantages are its simplicity and cost-effectiveness. This straightforward construction, consisting of a cavity side and a core side that separate at a single parting line, results in lower manufacturing and maintenance costs compared to more complex multi-plate or hot runner systems.

The core advantage of a two-plate mold is its direct and simple design, which minimizes tooling costs and simplifies operation. However, this simplicity inherently limits gating options and requires the part and its runner system to be ejected together, a critical trade-off that must influence your part design.

The Foundation: Simplicity and Cost-Effectiveness

The two-plate mold is the most common type of mold in injection molding for a reason. Its design is the simplest possible structure that can produce a part.

A Single Parting Line

A two-plate mold consists of two main sections, or plates: the cavity plate (A-side) and the core plate (B-side). The mold separates along a single plane, known as the parting line, to eject the finished part.

Lower Tooling and Manufacturing Costs

This simple construction requires less complex machining and fewer components than a multi-plate mold. This directly translates into a lower initial investment and a shorter lead time for tool manufacturing.

Reduced Maintenance Burden

With fewer moving parts, there are fewer potential points of failure. Maintenance is simpler, faster, and less costly, as access to the cavity, core, and ejector system is straightforward.

How Simplicity Translates to Operational Efficiency

The benefits of a two-plate mold extend beyond initial cost and into the production cycle itself, especially when matched with the right part design.

Faster, More Robust Cycles

The mechanical action of a two-plate mold is direct: it opens and it closes. This can lead to shorter cycle times as there is less required movement (mold stroke) compared to a three-plate mold which must open at two different parting lines.

Ideal for Single-Cavity and Large Parts

The robust and simple design is exceptionally well-suited for producing large parts from a single cavity. The forces within the mold are managed more directly, and the construction can handle high clamping pressures effectively.

Understanding the Trade-offs: Gating and Part Design

The primary advantages of a two-plate mold are also the source of its main limitations. The simplicity of the design imposes specific constraints on the part and runner system.

Limitation to Edge Gating

In a standard two-plate mold, the runner system that delivers plastic to the part must also be located on the parting line. This means the gate—the entry point for the plastic—is almost always on the edge or perimeter of the part. This can leave a cosmetic blemish that must be acceptable for the final product.

The Runner is Ejected with the Part

When the mold opens, the part and the attached runner system are ejected together as a single unit. This requires a secondary operation to separate the part from the runner, which can be done manually or through automation. This step adds labor cost and can affect the net cycle time.

Incompatibility with Center-Gated Designs

If a part requires a gate in its center for optimal plastic flow and dimensional stability (e.g., a gear or a round lid), a standard two-plate mold is not a viable option. Such designs require a three-plate mold or a hot runner system to deliver plastic to the center of the cavity.

Making the Right Choice for Your Project

Selecting the correct mold type is a critical decision that balances part requirements with your budget and production volume.

- If your primary focus is minimizing upfront tooling cost and lead time: A two-plate mold is the default and most economical choice, provided your part design is compatible with edge gating.

- If you are producing a simple, high-volume part where a gate mark on the edge is acceptable: The robust nature and operational efficiency of a two-plate mold make it a highly reliable solution.

- If your part requires a central gate or has complex features that demand precise flow control: You must consider a three-plate or hot runner system, as a two-plate mold's fundamental design will not meet your gating requirements.

By understanding these core principles, you can confidently select the mold architecture that aligns perfectly with your part design, budget, and production goals.

Summary Table:

| Advantage | Description |

|---|---|

| Cost-Effectiveness | Lower initial investment and manufacturing costs due to simpler design. |

| Simplicity & Reliability | Fewer moving parts lead to easier maintenance and fewer potential failures. |

| Operational Efficiency | Direct opening/closing action can enable faster cycle times for compatible parts. |

| Ideal for Large/Single Parts | Robust construction is well-suited for large parts from a single cavity. |

Ready to optimize your injection molding process with the right tooling?

At KINTEK, we specialize in providing robust and cost-effective solutions for your laboratory and production needs. Whether you're evaluating a simple two-plate mold for a new project or require more complex systems, our expertise in lab equipment and consumables ensures you get the right tool for the job.

We can help you:

- Reduce upfront tooling costs and shorten lead times.

- Simplify maintenance and improve production reliability.

- Select the perfect mold type for your specific part design and volume requirements.

Contact KINTEK today to discuss how our solutions can bring efficiency and value to your operation!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Assemble Lab Cylindrical Press Mold

- Special Shape Press Mold for Lab

- Cylindrical Press Mold for Lab Applications

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- What functions do high-strength molds serve in nanocopper hot pressing? Achieve Maximum Density and Plastic Flow

- What is the application of three plate mould? Achieve Balanced Flow for Complex Parts

- What is the function of graphite molds in Cu/WC vacuum hot pressing? Optimize Your Composite Sintering Process

- How should KBr powder be pre-treated before it is used to make a pellet? Optimize Your FTIR Spectra Quality

- How does the selection of a pressure mold affect the performance of all-solid-state batteries? Expert Pelletizing Guide

- Why are tungsten carbide (WC) molds required for hot-pressing battery materials? Ensure Density and Precision

- What is the difference between wet bag tooling and dry bag tooling? Choose the Right Composite Process

- How much does a production mold cost? A Strategic Guide to Injection Mold Pricing