For accurate and efficient X-Ray Fluorescence (XRF) analysis, the pressed pellet sample preparation method is a cornerstone technique. It delivers high-quality results by transforming powdered material into a dense, homogeneous sample. This approach is not only quick and low-cost but also provides superior analytical data compared to analyzing loose powders, especially for detecting elements in low concentrations.

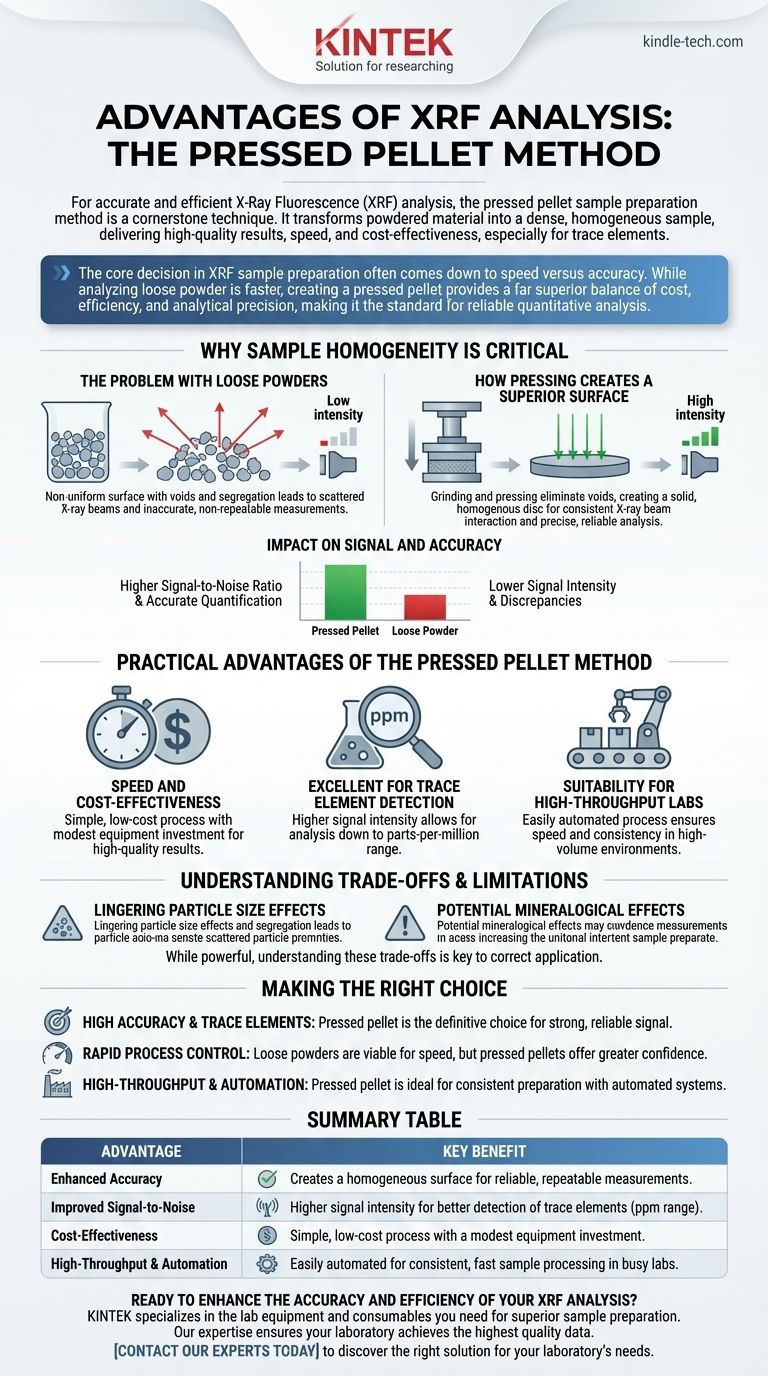

The core decision in XRF sample preparation often comes down to speed versus accuracy. While analyzing loose powder is faster, creating a pressed pellet provides a far superior balance of cost, efficiency, and analytical precision, making it the standard for reliable quantitative analysis.

Why Sample Homogeneity is Critical in XRF

The quality of your XRF results is directly tied to the quality of your sample surface. The primary goal of sample preparation is to present the instrument with a sample that is perfectly flat, dense, and chemically uniform.

The Problem with Loose Powders

Loose powders are inherently non-uniform. They contain void spaces between particles and suffer from segregation, where finer and denser particles settle at the bottom.

This inconsistent surface scatters the X-ray beam, reduces the signal intensity that reaches the detector, and can lead to inaccurate and non-repeatable measurements.

How Pressing Creates a Superior Surface

The pressed pellet method involves grinding a sample into a fine powder and then compressing it under high pressure. This process eliminates void spaces and creates a solid, flat, and homogenous disc.

This standardized surface ensures that the X-ray beam interacts consistently with the sample every time, forming the basis for precise and reliable analysis.

The Impact on Signal and Accuracy

A dense, pressed pellet produces a much higher signal-to-noise ratio. By minimizing voids and creating a uniform surface, more of the fluorescent X-rays generated from the sample reach the detector.

This results in higher signal intensities for most elements, which is critical for accurate quantification. Discrepancies observed in loose powders often disappear with pressed pellets, ensuring the results truly reflect the sample's composition.

The Practical Advantages of the Pressed Pellet Method

Beyond the physics, the pressed pellet technique offers significant operational benefits that make it a preferred choice in many laboratory and industrial settings.

Speed and Cost-Effectiveness

Preparing pressed pellets is a relatively simple and inexpensive process. The required equipment—typically a pulverizing mill and a sample press—is a modest investment for the significant improvement in data quality.

This makes it an accessible, low-cost approach for achieving high-quality analytical results.

Excellent for Trace Element Detection

The higher signal intensity achieved with pressed pellets makes the technique excellent for analyzing elements down to the parts-per-million (ppm) range. Where a signal might be lost in the noise of a loose powder sample, it becomes clear and quantifiable with a pellet.

Suitability for High-Throughput Labs

The pressed pellet preparation process can be easily automated. This is a major advantage for high-throughput environments like production control or commercial testing labs, ensuring both speed and consistency across a large number of samples.

Understanding the Trade-offs and Limitations

While powerful, the pressed pellet method is not without its limitations. Understanding these trade-offs is key to applying the technique correctly.

Lingering Particle Size Effects

Although grinding and pressing significantly reduce variability, they may not eliminate all particle size effects. If the sample is not ground finely enough, these effects can still influence the results, particularly for major elements with high concentrations.

Potential Mineralogical Effects

XRF results can be impacted by the mineral structure of the sample. Different minerals with the same elemental composition can sometimes yield slightly different results due to how their crystal structures absorb and fluoresce X-rays.

When Loose Powder Might Suffice

For some routine production control applications where calibration ranges are very narrow and speed is the absolute priority, analyzing loose powders can be a successful strategy. However, this always comes at the cost of precision and reliability compared to a pressed pellet.

Making the Right Choice for Your Analysis

Choosing your sample preparation method depends entirely on your analytical goals and operational needs.

- If your primary focus is high accuracy and trace element detection: The pressed pellet method is the definitive choice for its ability to produce a strong, reliable signal.

- If your primary focus is rapid process control with established standards: Loose powders can be a viable option for speed, but pressed pellets will always provide greater confidence in the data.

- If your primary focus is high-throughput and automation: The pressed pellet method is ideal due to its proven compatibility with automated systems for consistent preparation.

Ultimately, adopting the pressed pellet technique is a direct investment in the quality and reliability of your analytical data.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Enhanced Accuracy | Creates a homogeneous surface for reliable, repeatable measurements. |

| Improved Signal-to-Noise | Higher signal intensity for better detection of trace elements (ppm range). |

| Cost-Effectiveness | Simple, low-cost process with a modest equipment investment. |

| High-Throughput & Automation | Easily automated for consistent, fast sample processing in busy labs. |

Ready to enhance the accuracy and efficiency of your XRF analysis? The pressed pellet method is the industry standard for reliable quantitative results. KINTEK specializes in the lab equipment and consumables you need for superior sample preparation, from pulverizing mills to sample presses. Our expertise ensures your laboratory achieves the highest quality data. Contact our experts today to discuss your specific application and discover the right solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic pellet press contribute to SiCw/2024 aluminum composite preforms? Optimize Densification

- Why is a laboratory hydraulic press used for Li3V2(PO4)3 pellets? Optimize Solid-State Sintering for Li-ion Materials

- What is the function of a laboratory hydraulic press during the fabrication of Beta-Al2O3 solid electrolyte pellets?

- What is the significance of applying 200 MPa of pressure with a laboratory hydraulic pellet press for composite ceramics?