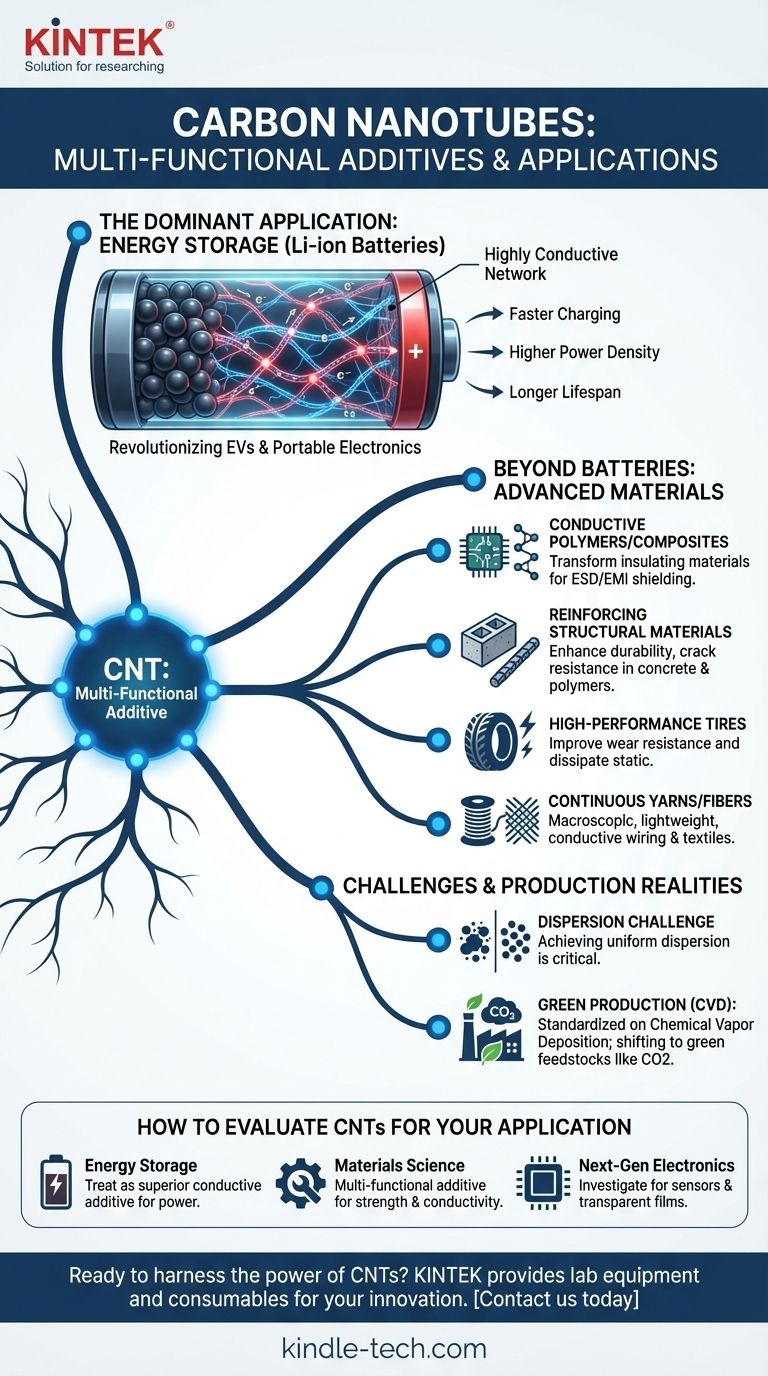

At its core, a carbon nanotube (CNT) is a multi-functional additive. Its primary commercial application today is as a highly conductive additive in the electrodes of lithium-ion batteries, where it significantly improves performance and longevity. Beyond batteries, CNTs are used to enhance advanced composites, polymers, concrete, and are being developed for next-generation electronics, sensors, and transparent conductive films.

While carbon nanotubes have been researched for decades across countless fields, their current, real-world impact is overwhelmingly concentrated in one area: making better batteries. Understanding their role as a performance-enhancing additive, rather than a standalone material, is the key to separating commercial reality from scientific hype.

The Dominant Application: Revolutionizing Energy Storage

The explosive growth of electric vehicles and portable electronics has created immense demand for better batteries. This is where carbon nanotubes have found their most significant and commercially successful application to date.

Enhancing Lithium-Ion Batteries

CNTs are primarily used as conductive additives within battery cathodes and anodes. They form a highly efficient, three-dimensional electrical network throughout the electrode material.

This network dramatically improves the battery's performance by enabling faster electron transport. The result is higher charge/discharge rates, increased energy density, and a longer operational lifespan.

Driving Market Growth and Consolidation

The demand from the battery industry is the main driver for the entire CNT market. This has led to a massive increase in production volumes and significant investment in new manufacturing capacity.

We are also seeing market consolidation, with major chemical and materials companies acquiring smaller CNT producers to secure their position in the rapidly expanding battery supply chain.

Beyond Batteries: Engineering Advanced Materials

While batteries are the lead application, the unique properties of CNTs allow them to function as powerful additives in a wide range of materials. The goal is always to impart a new property, like conductivity or strength, to a bulk material.

Conductive Polymers and Composites

Adding even a small percentage of CNTs can transform an insulating polymer or plastic into a conductive or semi-conductive material. This is critical for applications requiring electrostatic discharge (ESD) protection or electromagnetic interference (EMI) shielding.

Reinforcing Structural Materials

The exceptional strength and high aspect ratio of CNTs make them an effective reinforcing agent. When properly dispersed in materials like concrete, asphalt, or fiber-reinforced polymers, they can enhance durability, crack resistance, and overall mechanical strength.

Creating High-Performance Tires

In tires, CNTs serve a dual purpose. They can improve the mechanical properties of the rubber for better wear resistance while also providing the necessary conductivity to dissipate static electricity buildup.

The Promise of Continuous Yarns

A key area of innovation is spinning CNTs into continuous, macroscopic fibers or yarns. This transforms them from a powder additive into a structural material, opening the door for applications like lightweight, highly conductive wiring and advanced functional textiles.

Understanding the Trade-offs and Production Realities

The potential of CNTs is immense, but their practical application comes with significant technical and economic challenges. Understanding these hurdles is crucial for any real-world implementation.

The Dispersion Challenge

The single greatest challenge in using CNTs is dispersion. In their raw form, they tend to clump together due to strong intermolecular forces, which negates their benefits. Achieving a fine, uniform dispersion within a host material (like a polymer or battery slurry) is a complex process that is critical for success.

From Lab to Factory

Early production methods like laser ablation and arc discharge are not suitable for large-scale, cost-effective manufacturing. The industry has standardized on Chemical Vapor Deposition (CVD) as the dominant commercial process.

The Shift to Greener Production

Emerging research is focused on greener production methods. This includes using waste or captured carbon dioxide as a feedstock through electrolysis, or using methane pyrolysis, which can produce CNTs and clean hydrogen simultaneously.

How to Evaluate CNTs for Your Application

To leverage carbon nanotubes effectively, you must align their properties with your specific goal.

- If your primary focus is energy storage: Treat CNTs as a superior conductive additive to replace or augment traditional carbon black for improved battery power density and cycle life.

- If your primary focus is materials science: View CNTs as a multi-functional additive for enhancing mechanical strength while simultaneously introducing electrical or thermal conductivity into composites.

- If your primary focus is next-generation electronics: Investigate specialized, high-purity CNTs and advanced deposition techniques like PECVD for applications in sensors, thermal interface materials, and transparent films.

Ultimately, harnessing the power of carbon nanotubes requires moving past the idea of a miracle material and focusing on their strategic use as a high-impact additive.

Summary Table:

| Application Area | Key Use of CNTs | Primary Benefit |

|---|---|---|

| Energy Storage | Conductive additive in Li-ion battery electrodes | Higher power density, faster charging, longer lifespan |

| Advanced Composites | Reinforcement in polymers, concrete, tires | Increased strength, durability, and conductivity |

| Next-Gen Electronics | Transparent conductive films, sensors, thermal materials | Superior electrical and thermal properties |

Ready to harness the power of carbon nanotubes in your projects? KINTEK specializes in providing high-quality lab equipment and consumables for advanced materials research and development. Whether you're developing next-generation batteries, enhancing composite materials, or pushing the boundaries of electronics, our solutions support your innovation. Contact us today to discuss how we can help you achieve superior results with carbon nanotubes.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are sputtering targets used for? The Essential Source for Thin-Film Manufacturing

- What are carbon nanotubes advantages and disadvantages? Balancing Performance and Practicality

- What are the target materials for sputtering? From Metals to Ceramics for Precise Thin Films

- What are the properties and uses of mechanical thin films? Enhance Durability and Wear Resistance

- What is the structure of carbon nanomaterials? Unlocking Their Atomic Architecture for Innovation

- What is thin film in semiconductor? The Layered Foundation of Modern Microchips

- What are the disadvantages of ITO? Key Limitations for Flexible & Cost-Effective Electronics

- What uses thin films? Discover the Invisible Tech Powering Modern Devices