Pyrolysis gas, a byproduct of the pyrolysis process, has a wide range of applications across various industries. It is primarily used in power generation, chemical production, and waste management. The gas can be utilized as a fuel source, converted into biofuels, or processed for industrial applications. Additionally, it plays a role in reducing environmental impact by converting waste materials into valuable resources. The versatility of pyrolysis gas makes it a key component in sustainable energy solutions and industrial processes.

Key Points Explained:

-

Power Generation:

- Fuel Source: Pyrolysis gas can be directly used as a fuel in power plants to generate electricity. Its high caloric value makes it an efficient energy source.

- Combined Heat and Power (CHP): In CHP systems, pyrolysis gas is used to produce both electricity and useful heat, increasing overall energy efficiency.

- Renewable Energy: By converting waste materials into pyrolysis gas, it contributes to renewable energy production, reducing reliance on fossil fuels.

-

Chemical Production:

- Syngas Conversion: Pyrolysis gas, often referred to as syngas (a mixture of hydrogen and carbon monoxide), can be further processed to produce chemicals such as methanol, ammonia, and synthetic fuels.

- Feedstock for Chemical Synthesis: The gas serves as a feedstock for various chemical reactions, enabling the production of a wide range of industrial chemicals.

- Activated Carbon Production: Pyrolysis gas can be used in the production of activated carbon, which is widely used in water purification, air filtration, and chemical processing.

-

Waste Management and Recycling:

- Waste-to-Energy: Pyrolysis gas is a key component in waste-to-energy systems, where it helps convert municipal solid waste, industrial waste, and agricultural residues into energy.

- Reduction of Landfill Waste: By processing waste materials into pyrolysis gas, the volume of waste sent to landfills is significantly reduced, contributing to environmental sustainability.

- Sludge Reduction: In water treatment facilities, pyrolysis gas can be used to reduce the quantity of sludge generated during physico-chemical water purification processes.

-

Agricultural Applications:

- Soil Amendment: Bio-char, a byproduct of pyrolysis, can be used as a soil amendment to improve soil fertility and water retention.

- Pollutant Sorbent: Bio-char derived from pyrolysis gas can also act as a sorbent for pollutants, helping to clean contaminated soils and water bodies.

-

Industrial Applications:

- Biofuel Production: Pyrolysis gas can be refined into biofuels such as biodiesel and ethanol, which are used as transportation fuels.

- Industrial Heating: The gas can be used as a direct heat source in industrial processes, reducing the need for traditional fossil fuels.

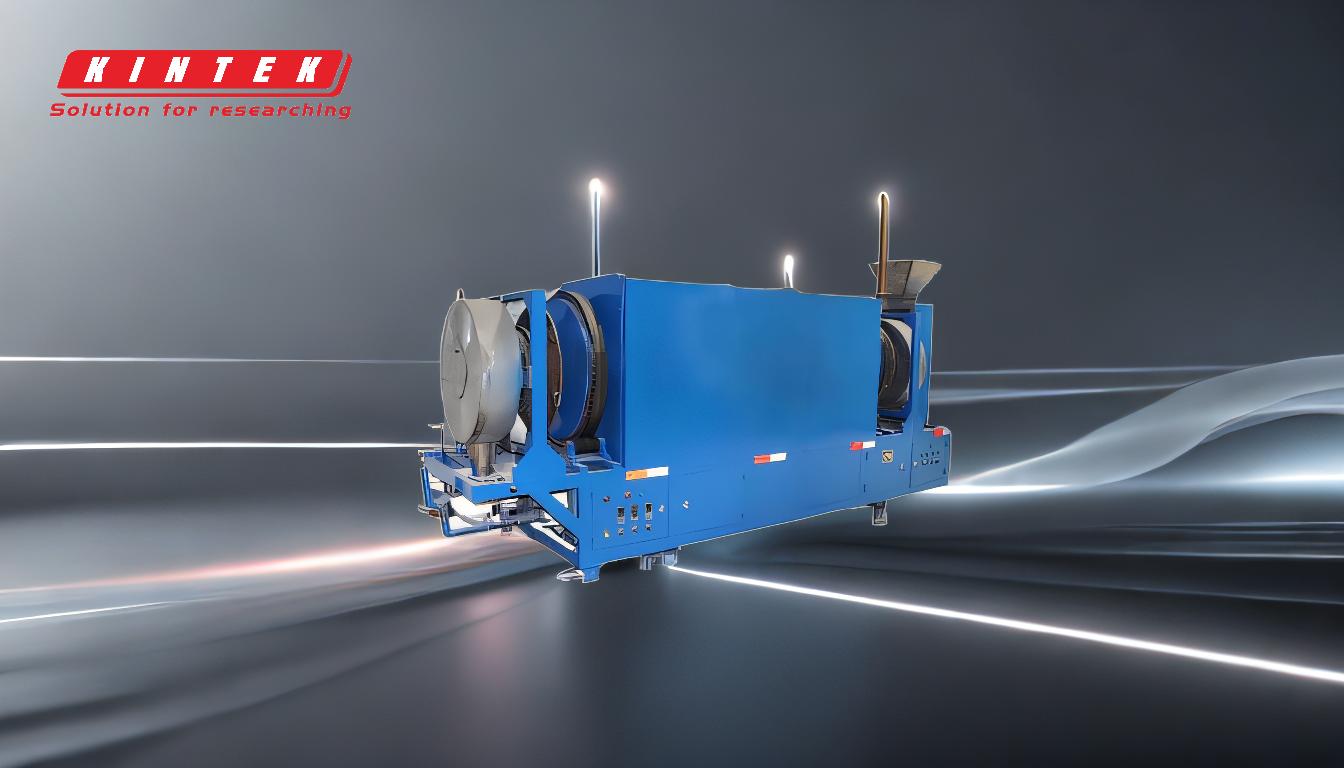

- Material Processing: Pyrolysis furnaces are used in industries to process materials under extreme conditions, enabling the study of material properties and the development of new materials.

-

Research and Development:

- Material Properties Study: Pyrolysis gas is used in research and development to study the properties of materials under high-temperature conditions, aiding in the development of new materials and technologies.

- Innovative Applications: Ongoing research explores new applications for pyrolysis gas, such as in carbon capture and storage (CCS) technologies, where it can be used to capture and store CO2 emissions.

In summary, pyrolysis gas is a versatile and valuable resource with applications spanning power generation, chemical production, waste management, agriculture, and industrial processes. Its ability to convert waste into energy and useful products makes it a key component in sustainable development and environmental conservation efforts.

Summary Table:

| Application | Key Uses |

|---|---|

| Power Generation | Fuel source for electricity, CHP systems, renewable energy production |

| Chemical Production | Syngas conversion, feedstock for chemical synthesis, activated carbon |

| Waste Management | Waste-to-energy systems, landfill waste reduction, sludge reduction |

| Agriculture | Soil amendment, pollutant sorbent |

| Industrial Processes | Biofuel production, industrial heating, material processing |

| Research & Development | Material properties study, innovative applications like carbon capture |

Discover how pyrolysis gas can transform your operations—contact us today for expert guidance!