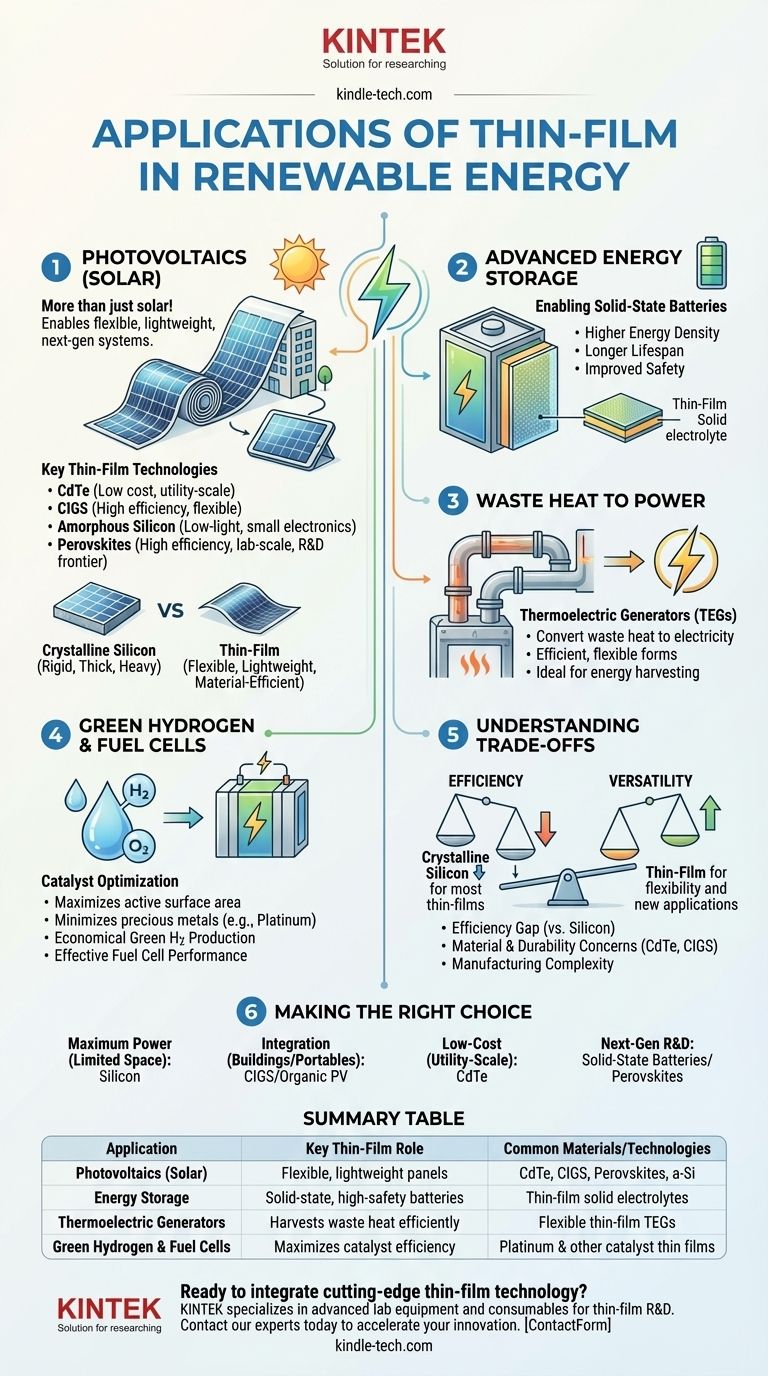

In renewable energy, thin-film technology is most famously applied to create flexible, lightweight solar panels. However, its role extends far beyond photovoltaics. It acts as a critical enabler for advanced energy storage, waste heat recovery, and the efficient production of green hydrogen, making it a cornerstone of next-generation energy systems.

The true value of thin-film technology in renewables is not just about replacing bulky materials, but about enabling entirely new capabilities. By depositing precise, functional layers of material onto a substrate, we can create flexible power sources, safer high-density batteries, and more efficient energy conversion devices that are impractical or impossible with traditional methods.

The Primary Application: Photovoltaics (Solar)

The most visible impact of thin-film technology is in the solar industry, where it offers a distinct alternative to conventional silicon wafers.

Crystalline Silicon vs. Thin-Film: A Fundamental Difference

Traditional solar panels use thick, rigid wafers of highly purified crystalline silicon (c-Si). They are durable and highly efficient but are also heavy, brittle, and energy-intensive to produce.

Thin-film photovoltaics (PV) are created by depositing one or more microscopic layers of photovoltaic material onto a substrate like glass, plastic, or metal. This process uses significantly less active material, leading to a lighter, and often flexible, final product.

Key Thin-Film Solar Technologies

Several types of thin-film solar cells are commercially available, each with unique properties:

- Cadmium Telluride (CdTe): The most common thin-film technology by market share, known for its low manufacturing cost and strong performance in utility-scale projects.

- Copper Indium Gallium Selenide (CIGS): Offers higher efficiency than other thin-films and excellent flexibility, making it ideal for integration into building materials (BIPV) or portable applications.

- Amorphous Silicon (a-Si): The oldest thin-film technology. While its efficiency is lower, it's very cheap to produce and performs well in low-light conditions, making it suitable for small electronics.

The Next Frontier: Perovskite Solar Cells

Perovskites are a relatively new class of thin-film materials that have achieved staggering efficiency gains in laboratory settings, rivaling and even exceeding traditional silicon. They promise low-cost, high-efficiency solar, but researchers are still working to overcome challenges with long-term stability and durability.

Beyond Solar: Enabling the Broader Energy System

While solar is the leading application, thin-films are quietly revolutionizing other critical areas of the renewable energy ecosystem.

Advanced Energy Storage: Thin-Film Batteries

Solid-state batteries are a key next-generation technology that replaces the flammable liquid electrolyte in current lithium-ion batteries with a solid material.

Thin-film deposition is a primary method for creating these solid electrolytes. The resulting thin-film batteries promise higher energy density, a longer lifespan, and vastly improved safety, making them ideal for everything from electric vehicles to grid-scale storage.

Waste Heat to Power: Thermoelectric Generators

A vast amount of energy is lost as waste heat in industrial processes, power plants, and combustion engines. Thermoelectric generators (TEGs) can convert this heat directly into useful electricity.

Thin-film TEGs are more efficient and can be manufactured in flexible forms to conform to hot surfaces like pipes or engines, enabling a new class of energy harvesting that improves overall system efficiency.

Green Hydrogen and Fuel Cells

The efficiency of both electrolyzers (which use electricity to split water into hydrogen and oxygen) and fuel cells (which convert hydrogen back into electricity) depends heavily on their catalysts.

Applying catalysts as a precisely controlled thin film maximizes the active surface area while minimizing the use of expensive precious metals like platinum. This makes the production of green hydrogen more economical and the performance of fuel cells more effective.

Understanding the Trade-offs: Efficiency vs. Versatility

Thin-film technology is not a universal solution. Its adoption requires a clear understanding of its inherent trade-offs.

The Efficiency Gap

With the exception of lab-scale perovskites, most commercially available thin-film solar technologies have lower conversion efficiencies than their mainstream crystalline silicon counterparts. This means they require more surface area to produce the same amount of power.

Material and Durability Concerns

Some thin-film materials present challenges. CdTe uses cadmium, a toxic heavy metal that requires careful handling and end-of-life recycling. CIGS relies on indium and gallium, which are rarer and more expensive than silicon. Long-term degradation and moisture sensitivity can also be a greater concern for some thin-film types compared to robust silicon panels.

Manufacturing Complexity

While thin-film PV uses less raw material, the deposition equipment (e.g., for sputtering or chemical vapor deposition) can represent a significant capital investment. The processes require precise vacuum conditions and control, making the manufacturing technology highly sophisticated.

Making the Right Choice for Your Goal

The ideal thin-film application depends entirely on the specific engineering or investment objective.

- If your primary focus is maximum power output in a limited space: Traditional crystalline silicon panels still lead due to their high, proven efficiency.

- If your primary focus is integrating power into buildings, vehicles, or portable electronics: The flexibility and light weight of CIGS or organic PV are unmatched.

- If your primary focus is low-cost, utility-scale solar generation: CdTe thin-film panels are a highly competitive and proven choice.

- If your primary focus is next-generation energy storage or R&D: Thin-film solid-state batteries and perovskite solar cells represent the frontier, promising significant breakthroughs.

Ultimately, thin-film technology provides a powerful and versatile toolset for designing a more efficient, integrated, and adaptable renewable energy future.

Summary Table:

| Application | Key Thin-Film Role | Common Materials/Technologies |

|---|---|---|

| Photovoltaics (Solar) | Creates flexible, lightweight panels | CdTe, CIGS, Perovskites, Amorphous Silicon |

| Energy Storage | Enables solid-state, high-safety batteries | Thin-film solid electrolytes |

| Thermoelectric Generators | Harvests waste heat efficiently | Flexible thin-film TEGs |

| Green Hydrogen & Fuel Cells | Maximizes catalyst efficiency | Platinum and other catalyst thin films |

Ready to integrate cutting-edge thin-film technology into your renewable energy projects? KINTEK specializes in advanced lab equipment and consumables for thin-film research and development, including deposition systems and material solutions. Whether you're developing next-generation perovskite solar cells, solid-state batteries, or efficient catalysts for green hydrogen, our expertise supports your innovation. Contact our experts today to discuss how we can accelerate your R&D and production processes.

Visual Guide

Related Products

- Evaporation Boat for Organic Matter

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

People Also Ask

- What are the advantages of thin film over thick film? Achieve Unmatched Precision and Stability

- What are the optical properties of CVD diamond? Unlock Unmatched Performance for Demanding Applications

- What are the synthesis and purification methods for carbon nano tubes? Scaling Quality and Purity for Your Application

- What is the use of RF sputtering? Essential for Depositing High-Quality Insulating Films

- What are the advantages and applications of thin film technology? Unlock Advanced Material Performance

- What is the biggest obstacle for producing graphene? The Cost, Quality, and Scale Dilemma

- What is the thickness of CVD graphene? From Single-Atom Layers to Precise Multi-Layer Control

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability