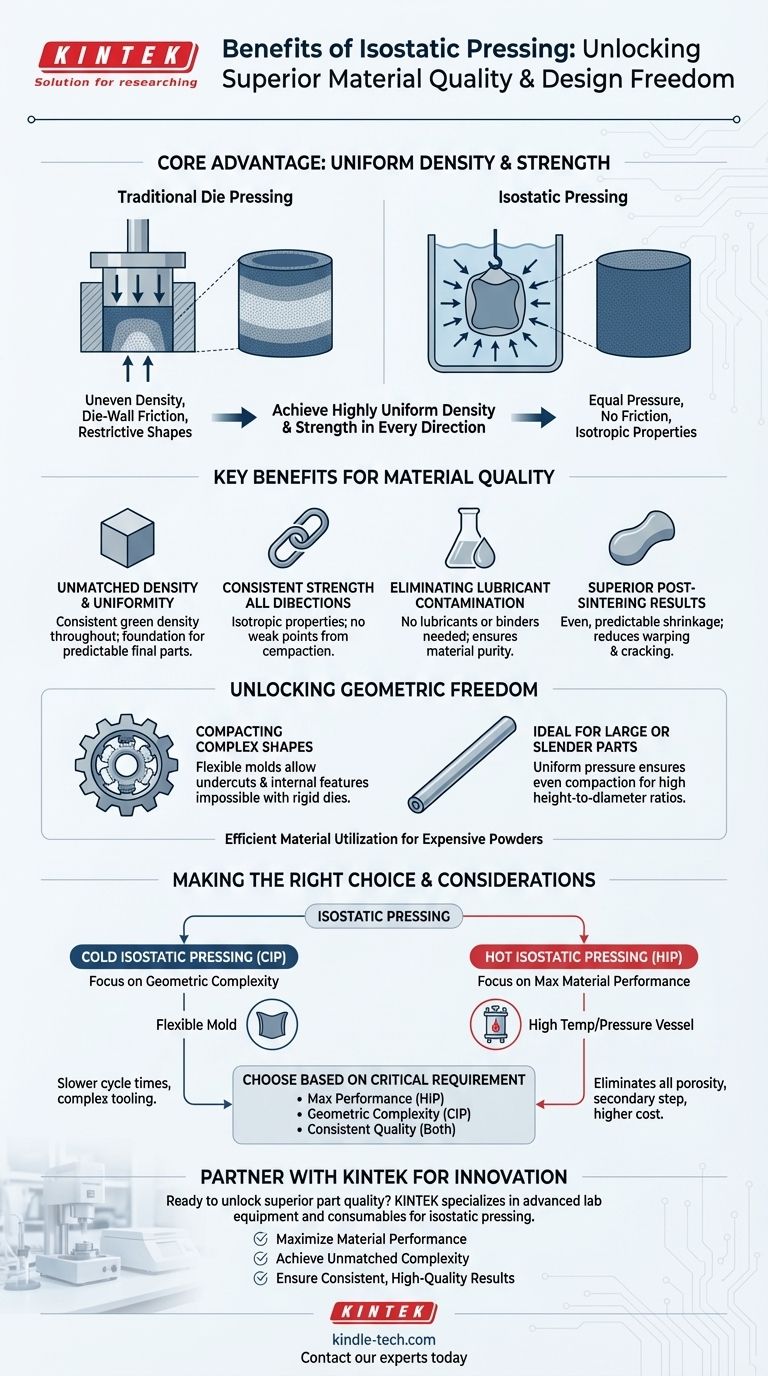

The core advantage of isostatic pressing is its ability to produce parts with highly uniform density and strength in every direction. This process compacts material powders using equal pressure from all sides, overcoming the geometric and material limitations inherent in traditional unidirectional pressing methods.

Isostatic pressing solves the fundamental problems of traditional die pressing—uneven density and restrictive shapes—by using fluid pressure to compact powders uniformly. This results in superior material properties and unparalleled design freedom.

The Fundamental Principle: Uniform Pressure

The unique benefits of isostatic pressing all stem from a single, powerful concept: applying pressure equally to every surface of the part being formed.

Eliminating Die-Wall Friction

In traditional uniaxial pressing, a piston pushes powder into a rigid die. Friction between the powder and the die walls causes density to vary, with the center of the part being less dense than the areas near the piston.

Isostatic pressing places the powder in a flexible mold and immerses it in a fluid. Because the pressure is transmitted through the fluid, it acts perpendicular to every surface, completely eliminating die-wall friction.

Achieving Isotropic Properties

This uniform compaction results in isotropic material properties, meaning the part's strength and other mechanical characteristics are the same regardless of the direction in which they are measured.

Key Benefits for Material Quality

The quality of an isostatically pressed part is consistently higher than what can be achieved with other powder compaction methods.

Unmatched Density and Uniformity

By applying pressure evenly, the process achieves a much more uniform green density throughout the entire component. This consistency is the foundation for predictable and reliable final parts.

Consistent Strength in All Directions

The uniform density directly translates to uniform strength. There are no weak points or internal inconsistencies caused by the compaction process itself.

Eliminating Lubricant Contamination

Uniaxial pressing often requires adding lubricants to the powder to reduce die friction. Isostatic pressing requires no lubricants or wax binders, which simplifies the manufacturing process by eliminating the "dewaxing" step and, more importantly, prevents contamination of the final material.

Superior Post-Sintering Results

Because the initial "green" part is so uniform, it shrinks evenly and predictably during the final sintering stage. This dramatically reduces the risk of warping, cracking, or internal stresses.

Unlocking Geometric Freedom

Isostatic pressing liberates engineers from the design constraints imposed by rigid dies, allowing for a new class of component shapes.

Compacting Complex Shapes

The use of flexible, elastomeric molds means designers can create complex geometries, including undercuts and internal cavities, that are impossible to form or eject from a rigid die.

Ideal for Large or Slender Parts

The process excels at producing parts with large height-to-diameter ratios. Uniform pressure ensures that even long, slender parts are compacted evenly from end to end.

Efficient Use of Materials

Isostatic pressing provides highly efficient material utilization, a critical benefit when working with expensive or difficult-to-compact powders like ceramics, composites, and refractory metals.

Understanding the Trade-offs and Considerations

While powerful, isostatic pressing is a specialized technique with specific considerations.

Tooling and Cycle Times

The flexible molds used in Cold Isostatic Pressing (CIP) are more complex than simple dies and may have a shorter lifespan. The process of loading, pressurizing, and unloading the pressure vessel generally results in longer cycle times compared to high-speed uniaxial pressing.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is often a secondary step performed after an initial forming process. It uses high temperature and pressure to completely eliminate any remaining porosity in a part, but this adds significant time and cost.

Not a Universal Replacement

Isostatic pressing is not a direct replacement for all powder compaction needs. It is best suited for applications where material performance, uniform density, or geometric complexity are the primary drivers and justify the process's specific requirements.

Making the Right Choice for Your Goal

Select this process based on the most critical requirement for your component.

- If your primary focus is maximum material performance: Use Hot Isostatic Pressing (HIP) to eliminate all porosity, dramatically increasing fatigue life, wear resistance, and durability.

- If your primary focus is geometric complexity: Cold Isostatic Pressing (CIP) provides the design freedom to create intricate shapes that are impossible with uniaxial methods.

- If your primary focus is consistent part quality: The uniform density from isostatic pressing ensures predictable shrinkage and isotropic strength, especially for large or slender parts.

By leveraging its unique method of uniform compaction, isostatic pressing enables you to achieve a level of quality and design sophistication that other methods cannot match.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Uniform Density & Strength | Isotropic properties; consistent in all directions | Maximizing material performance and reliability |

| Geometric Freedom | Complex shapes, undercuts, large height-to-diameter ratios | Innovative designs impossible with rigid dies |

| Material Purity | No lubricants needed; eliminates contamination | High-purity ceramics, composites, and metals |

| Predictable Sintering | Even shrinkage reduces warping and cracking | Consistent, high-quality final parts |

Ready to unlock superior part quality and design freedom with isostatic pressing?

At KINTEK, we specialize in providing advanced lab equipment and consumables for materials research and development. Our expertise in isostatic pressing technologies can help you achieve:

- Maximum Material Performance: Eliminate porosity and achieve isotropic strength.

- Unmatched Geometric Complexity: Create intricate shapes and large, slender parts.

- Consistent, High-Quality Results: Ensure predictable sintering and superior final parts.

Let KINTEK be your partner in innovation. Contact our experts today to discuss how our solutions can meet your specific laboratory needs and drive your projects forward.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- How does an isostatic work? Achieve Uniform Density and Complex Shapes with Isostatic Pressing

- What are the advantages of using a Cold Isostatic Press for perovskite solar cells? Unlock High-Pressure Performance

- What is the difference between HIP and CIP? A Guide to Shaping vs. Densification

- What are the applications of isostatic pressing technology? Achieve Superior Material Density and Uniformity

- What advantages does a Cold Isostatic Press (CIP) offer for solid-state batteries? Superior Density & Uniformity

- What is cold isostatic pressure? Achieve Uniform Density for Complex Powder Parts

- What is the critical role of a Cold Isostatic Press (CIP)? Enhance LSTH Perovskite Solid Electrolyte Densification

- Why is a Cold Isostatic Press (CIP) used for copper composite powders? Enhance Sintering Efficiency and Density