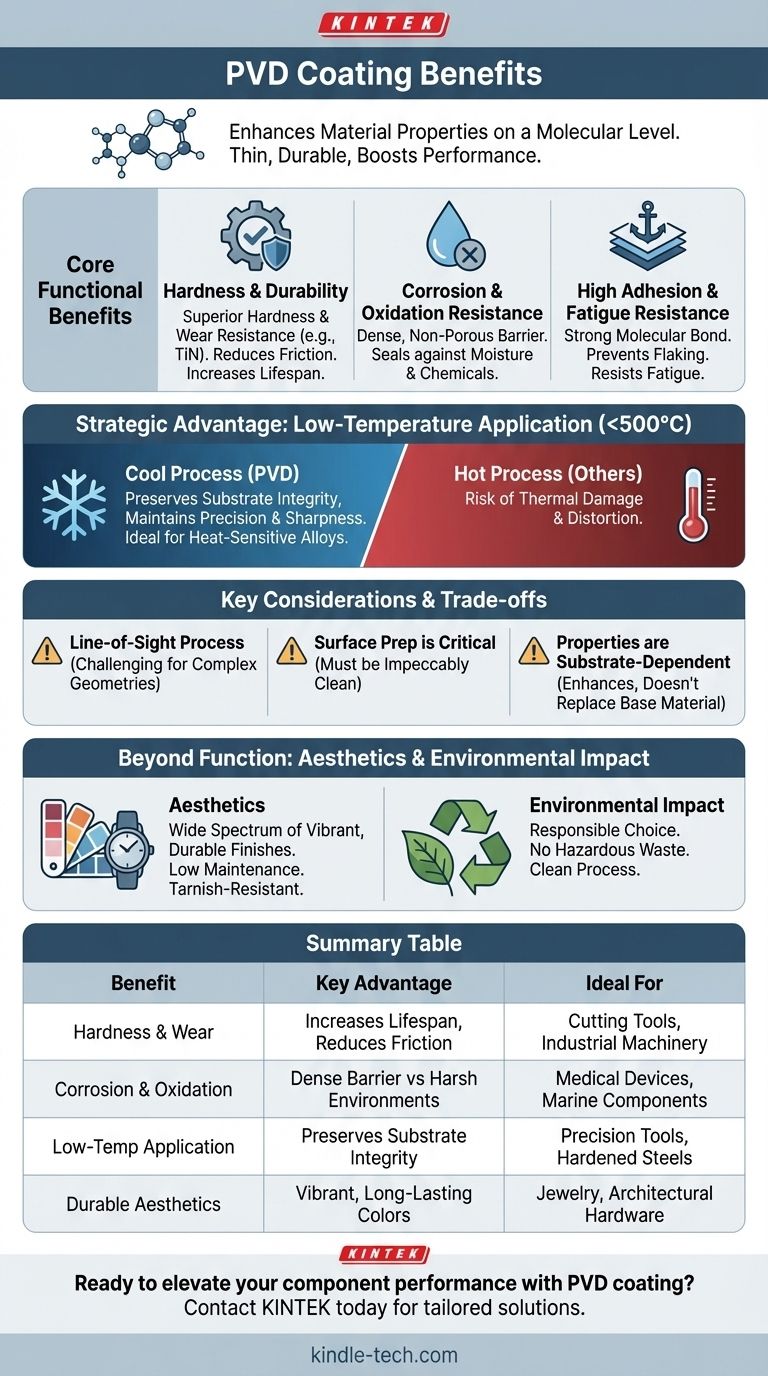

In essence, Physical Vapor Deposition (PVD) is a finishing process that fundamentally enhances a material's properties on a molecular level. It provides a remarkably thin yet extremely durable coating that boosts performance by increasing hardness, wear resistance, and corrosion resistance. These functional benefits are delivered through an environmentally clean process that also offers a wide array of decorative finishes.

PVD coating is not merely a surface layer; it's a strategic enhancement. It improves a component's performance and durability without altering the core structure of the base material, making it an ideal solution for precision, high-stress, and aesthetic applications.

The Core Functional Benefits: Hardness and Durability

The primary reason professionals turn to PVD is to dramatically increase the operational lifespan and resilience of a part or tool. This is achieved through several key mechanisms.

Superior Hardness and Wear Resistance

PVD applies thin films of ceramic or composite materials, such as Titanium Nitride (TiN), that are significantly harder than the underlying substrate.

This added hardness directly reduces friction between moving parts and protects against abrasive wear, extending the life of components from cutting tools to industrial machinery.

Excellent Corrosion and Oxidation Resistance

The PVD process creates a dense, non-porous coating that acts as a robust barrier between the substrate and its environment.

This barrier effectively seals the material from moisture, chemicals, and oxygen, providing exceptional protection against both corrosion and high-temperature oxidation.

High Adhesion and Fatigue Resistance

PVD creates a strong molecular bond to the substrate material, ensuring the coating will not flake, peel, or delaminate under stress.

Furthermore, the process often imparts compressive stress into the surface, which helps prevent the formation and propagation of micro-cracks. This makes PVD-coated parts more resistant to fatigue, especially in interrupted processes like milling.

The Strategic Advantage: Low-Temperature Application

Unlike many other high-performance coating processes, PVD operates at relatively low temperatures, typically around 500°C or less. This characteristic is a significant strategic advantage.

Preserving Substrate Integrity

Higher-temperature processes can cause thermal damage, distortion, or an undesirable change in the hardness (temper) of the base material.

Because PVD is a "cool" process, it can be safely applied to heat-sensitive alloys and pre-hardened steels without compromising their engineered properties.

Maintaining Precision and Sharpness

PVD coatings are exceptionally thin, often ranging from just 0.5 to 5 microns.

This ensures that the process does not alter a part's critical dimensions or tolerances. For cutting tools, it means the blade's sharpness is preserved, which reduces cutting force and heat generation during use.

Understanding the Trade-offs and Considerations

While powerful, PVD is not a universal solution. Understanding its limitations is key to successful implementation.

It's a Line-of-Sight Process

The PVD process deposits material in a direct line of sight from the source. This means it can be challenging to achieve a uniform coating on parts with highly complex internal geometries or hidden surfaces.

Substrate Preparation is Critical

The performance of a PVD coating is entirely dependent on the quality of the surface to which it is applied. The substrate must be impeccably clean and free of any contaminants for the coating to achieve proper adhesion.

Properties are Substrate-Dependent

The coating enhances, but does not replace, the properties of the base material. A hard PVD coating on a very soft substrate can still fail if the underlying material deforms under load. The final performance is a synergy between the coating and the substrate.

Beyond Function: Aesthetics and Environmental Impact

PVD also delivers significant value in applications where appearance and environmental responsibility are paramount.

A Wide Spectrum of Decorative Finishes

PVD can produce a vast range of vibrant colors and attractive textures that are far more durable than traditional plating or painting. This makes it a preferred choice for high-wear decorative items like jewelry, watches, and architectural hardware.

Low Maintenance and Long-Lasting Appearance

The inherent durability and resistance to corrosion mean PVD finishes do not tarnish, pit, or fade, even when exposed to harsh conditions like sandblasting or coastal air.

A Responsible Choice

PVD is one of the most environmentally friendly coating processes available. It produces no hazardous waste or harmful gases and does not alter the inherent recyclable value of the base material, such as stainless steel.

Making the Right Choice for Your Goal

To leverage PVD effectively, align its benefits with your specific objective.

- If your primary focus is extending tool life: PVD's combination of extreme hardness, low friction, and high adhesion is its most valuable benefit for cutting, milling, and molding.

- If your primary focus is corrosion protection: The dense, non-porous barrier created by PVD is ideal for protecting components in harsh chemical or environmental conditions.

- If your primary focus is durable aesthetics: PVD offers a wide range of vibrant, long-lasting colors and finishes that resist wear, fading, and tarnishing.

- If your primary focus is coating heat-sensitive or precision parts: The low processing temperature and exceptionally thin application make PVD the superior choice over high-heat or dimension-altering alternatives.

By understanding these core benefits, you can strategically apply PVD to elevate the performance, longevity, and value of your components.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Hardness & Wear Resistance | Increases component lifespan, reduces friction | Cutting tools, industrial machinery |

| Corrosion & Oxidation Resistance | Dense, non-porous barrier against harsh environments | Medical devices, marine components |

| Low-Temperature Application | Preserves substrate integrity; ideal for heat-sensitive materials | Precision tools, hardened steels |

| Durable Aesthetics | Wide range of vibrant, long-lasting colors and finishes | Jewelry, watches, architectural hardware |

| Environmental Responsibility | Clean process with no hazardous waste | Sustainable manufacturing applications |

Ready to elevate your component performance with PVD coating?

At KINTEK, we specialize in advanced lab equipment and consumables, including PVD coating solutions tailored to your specific needs. Whether you're looking to extend tool life, enhance corrosion protection, or achieve durable decorative finishes, our expertise ensures optimal results.

Contact us today to discuss how our PVD coating solutions can bring superior durability, performance, and value to your laboratory or manufacturing processes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition