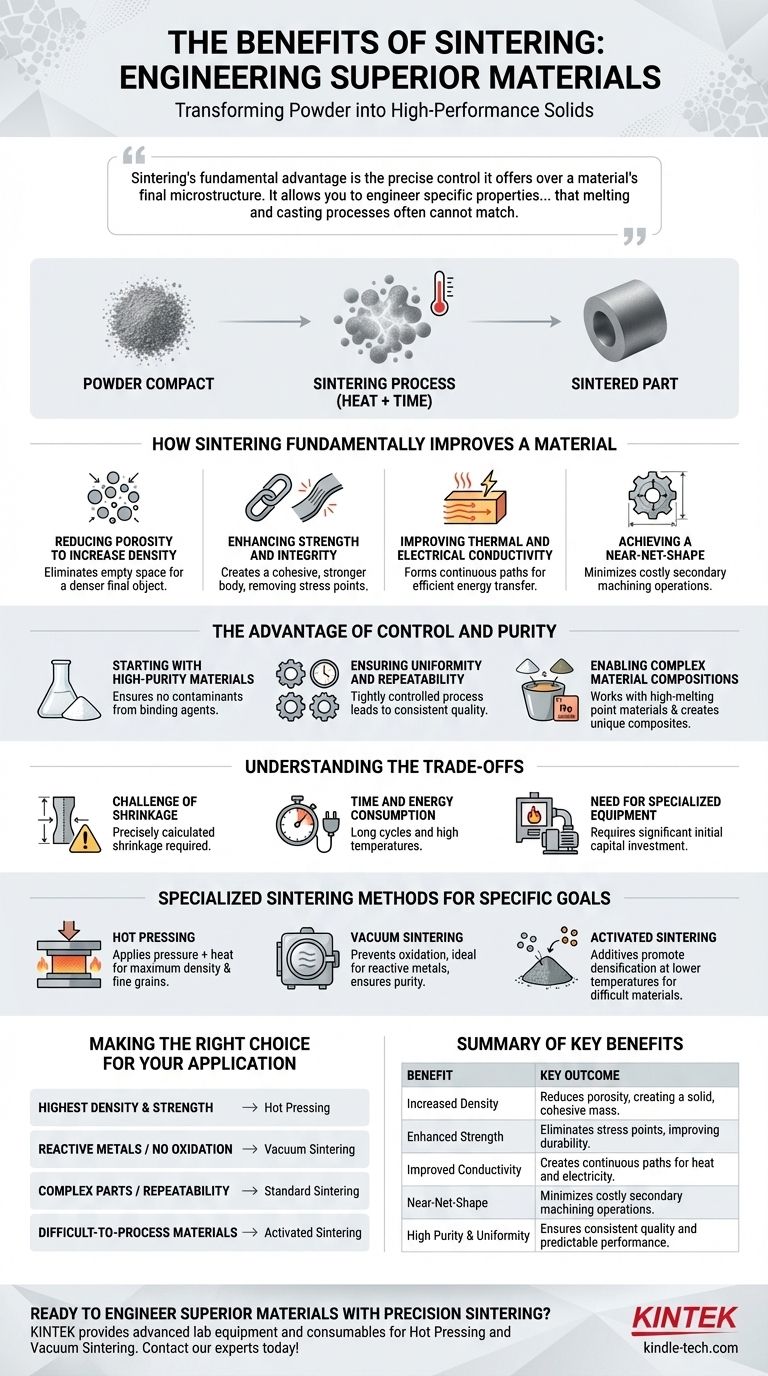

At its core, sintering is a manufacturing process that transforms a powder into a solid mass using heat, resulting in materials with superior strength, density, and conductivity. The primary benefits include the ability to create highly uniform, near-net-shape parts with engineered properties, especially for materials with extremely high melting points that are difficult to process by other means.

Sintering's fundamental advantage is the precise control it offers over a material's final microstructure. It allows you to engineer specific properties like density, strength, and conductivity from the powder up, a level of control that melting and casting processes often cannot match.

How Sintering Fundamentally Improves a Material

Sintering is not simply about heating a powder; it is a process of atomic diffusion that fundamentally changes the material's internal structure and, consequently, its performance characteristics.

Reducing Porosity to Increase Density

The most immediate effect of sintering is the reduction of empty space, or porosity, between the initial powder particles. As particles fuse, the voids between them shrink and close, leading to a denser final object.

Enhancing Strength and Integrity

A direct result of increased density is enhanced mechanical strength. By eliminating the pores that act as microscopic stress points, sintering creates a solid, cohesive body that is significantly stronger and more durable than the initial powder compact.

Improving Thermal and Electrical Conductivity

Pores and loose particle boundaries act as barriers to the flow of heat and electricity. Sintering creates continuous, solid-state bonds between particles, forming an uninterrupted path that dramatically improves both thermal and electrical conductivity.

Achieving a Near-Net-Shape

Sintering allows for the creation of complex objects that are very close to their final desired dimensions. This near-net-shape capability minimizes the need for costly and wasteful secondary machining operations.

The Advantage of Control and Purity

Beyond the physical improvements, sintering provides an unparalleled level of process control, which is critical for high-performance applications.

Starting with High-Purity Materials

The process begins with powders, which can be manufactured to exceptionally high levels of purity. This ensures that no unwanted contaminants or inclusions from binding agents are trapped within the final product.

Ensuring Uniformity and Repeatability

Because the starting powder's grain size and the process parameters (temperature, time, atmosphere) are tightly controlled, sintering is a highly repeatable operation. This leads to consistent quality and predictable performance from one part to the next.

Enabling Complex Material Compositions

Sintering makes it possible to create components from materials that are otherwise very difficult to work with, such as tungsten or molybdenum, due to their extremely high melting points. It also allows for the mixing of different powders to create unique composites.

Understanding the Trade-offs

While powerful, sintering is not without its considerations. Understanding its limitations is key to using it effectively.

The Challenge of Shrinkage

As porosity is eliminated, the part will inevitably shrink. This shrinkage must be precisely calculated and accounted for in the initial mold design to achieve accurate final dimensions.

Time and Energy Consumption

Sintering cycles can be lengthy, often lasting for many hours. The high temperatures required also translate to significant energy consumption, which can impact overall cost.

The Need for Specialized Equipment

Processes like vacuum sintering or hot pressing require expensive, specialized furnaces and presses. This initial capital investment can be a significant barrier for some applications.

Specialized Sintering Methods for Specific Goals

Different variations of sintering have been developed to optimize for specific outcomes, each offering a unique set of advantages.

Hot Pressing for Maximum Density

This method applies external pressure simultaneously with heat. This aids mass transfer, reduces the required sintering temperature and time, and is exceptionally effective at producing fine-grained parts that approach 100% theoretical density.

Vacuum Sintering for Ultimate Purity

Performing the process in a vacuum prevents the material from reacting with atmospheric gases like oxygen. This is critical for reactive metals and results in a clean, bright surface finish free from oxidation.

Activated Sintering for Difficult Materials

For materials with limited sinterability, "activators" can be added to the powder. This technique promotes densification at lower temperatures and provides enhanced control over the final microstructure and grain growth.

Making the Right Choice for Your Application

Selecting the right approach depends entirely on your project's end goal.

- If your primary focus is achieving the absolute highest material density and strength: Consider hot pressing to combine heat and pressure, which effectively minimizes porosity and inhibits grain growth.

- If your primary focus is working with reactive metals or preventing any surface oxidation: Vacuum sintering is the ideal choice to ensure a pure, uncontaminated, and bright final product.

- If your primary focus is creating complex, near-net-shape parts with high repeatability: Standard sintering offers an excellent balance of control over the final geometry and microstructure.

- If your primary focus is improving the sinterability of a difficult-to-process material: Activated sintering can lower the process requirements and improve densification.

Ultimately, leveraging sintering effectively is about choosing the right process to transform simple powders into highly engineered components.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Increased Density | Reduces porosity, creating a solid, cohesive mass. |

| Enhanced Strength | Eliminates stress points, improving durability. |

| Improved Conductivity | Creates continuous paths for heat and electricity. |

| Near-Net-Shape | Minimizes costly secondary machining operations. |

| High Purity & Uniformity | Ensures consistent quality and predictable performance. |

Ready to engineer superior materials with precision sintering? KINTEK specializes in providing the advanced lab equipment and consumables needed for sintering processes like hot pressing and vacuum sintering. Whether you're working with reactive metals or aiming for maximum density, our solutions help you achieve the exact material properties you require. Contact our experts today to discuss how we can support your laboratory's specific sintering needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the effects of temperature in metal working process? Master Strength, Ductility, and Microstructure

- Why is energy consumption a critical consideration for ULT freezers? Key to Balancing Performance, Cost, and Sustainability

- What is the function of laboratory high-temperature ovens? Master Biomass Hydrothermal Conversion Control

- How do you bond steel to steel without welding? Master Structural Adhesives & Mechanical Fasteners

- What is the temperature range for annealing? Master Material-Specific Heat Treatment

- What is the advantage of sputtering? Achieve Superior, High-Purity Thin Films from Any Material

- Why is it necessary to configure efficient cold traps in membrane distillation? Ensure Flux Stability & Data Accuracy

- What is the difference between submerged arc furnace and electric arc furnace? Choosing the Right Smelting vs. Melting Technology