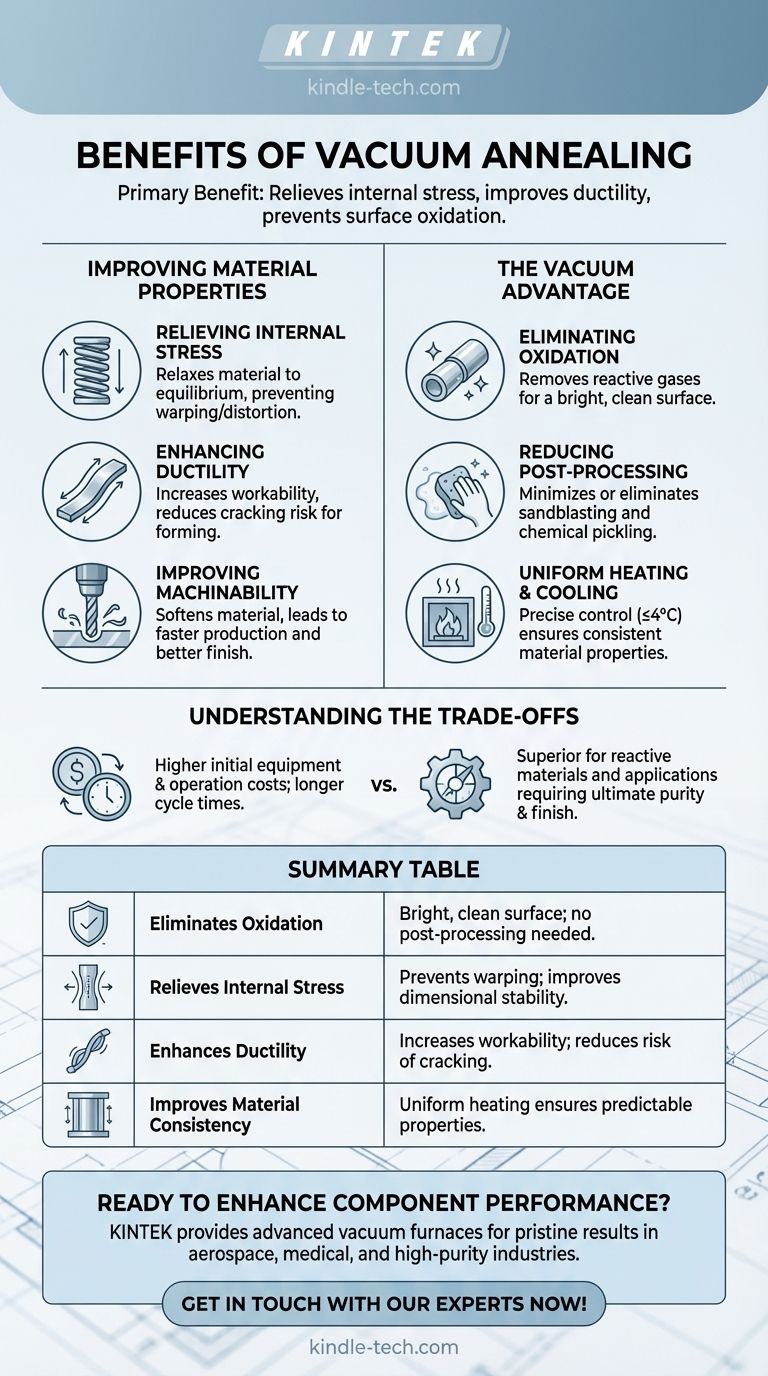

The primary benefit of vacuum annealing is its ability to relieve internal stress and improve a material's ductility in a highly controlled environment that prevents surface oxidation. This process heats a material, holds it at a specific temperature, and cools it—all within a vacuum—resulting in a clean, bright part that requires minimal post-processing.

Vacuum annealing delivers the metallurgical benefits of traditional annealing—such as softening and stress relief—without the damaging surface reactions that occur when heating metals in air. This focus on purity and control is its defining advantage.

The Core Purpose: Improving Material Properties

Annealing is a foundational heat treatment process designed to alter a material's internal structure, making it more suitable for subsequent manufacturing steps or for its final application.

Relieving Internal Stress

Manufacturing processes like work hardening, machining, or grinding introduce significant stress into a material's crystal structure. Vacuum annealing allows the material to relax back to an equilibrium state, which prevents warping or distortion during later high-temperature treatments.

Enhancing Ductility and Workability

A key outcome of annealing is increased ductility—the ability of a material to deform without fracturing. This process restores the material's workability after it has been hardened, allowing for additional forming, bending, or drawing without the risk of cracking.

Improving Machinability

By softening the material and relieving internal hardness, annealing makes it significantly easier to machine. This can lead to faster production times, reduced tool wear, and a better surface finish on the final part.

The "Vacuum" Advantage: A Pristine Environment

Using a vacuum furnace elevates the standard annealing process by providing a clean, non-reactive atmosphere. This is where the most significant benefits are realized.

Eliminating Oxidation and Contamination

When metals are heated in the presence of oxygen, they form a layer of oxide scale on the surface. A vacuum removes these reactive gases, ensuring the part emerges from the furnace with a bright, clean surface. This is especially critical for parts with complex internal geometries, like impellers or pump units.

Reducing Post-Processing Costs

Because vacuum annealing prevents surface contamination, it dramatically reduces or eliminates the need for subsequent cleaning operations like sandblasting or chemical pickling. This results in faster, cheaper, and safer post-processing for the customer.

Ensuring Uniform Heating and Cooling

Modern vacuum furnaces offer exceptional temperature uniformity (often within ≤4°C). This precise control ensures that the entire workpiece receives the exact same thermal treatment, leading to highly consistent and predictable material properties throughout the part.

Improving Final Part Performance

A clean, oxide-free surface directly contributes to improved corrosion resistance. By avoiding surface defects and inconsistencies caused by atmospheric reactions, the finished component is more reliable and has a longer service life.

Understanding the Trade-offs

While highly effective, vacuum annealing involves specific considerations that make it more suitable for certain applications than others.

Equipment and Initial Cost

Vacuum furnaces are sophisticated pieces of equipment that represent a higher capital investment compared to standard atmospheric furnaces. The cost of operation, including energy and maintenance, can also be higher.

Process Cycle Time

Achieving a deep vacuum and allowing the part to cool slowly within the furnace can result in longer cycle times compared to some open-air or forced-convection methods.

Material and Application Specificity

The benefits of vacuum annealing are most pronounced for materials that are highly reactive with oxygen (like titanium or certain stainless steels) or for applications where surface finish and purity are absolutely non-negotiable.

Making the Right Choice for Your Goal

Selecting the right heat treatment depends entirely on the requirements of your component and your overall manufacturing goals.

- If your primary focus is ultimate surface purity: Choose vacuum annealing for parts where any oxidation is unacceptable, such as in medical, aerospace, or high-purity fluid applications.

- If your primary focus is mechanical consistency: The precise temperature control of vacuum annealing makes it ideal for critical components that require highly repeatable ductility and stress relief.

- If your primary focus is simple stress relief on a non-critical part: A less expensive atmospheric annealing process may be sufficient if the resulting surface scale can be easily and economically removed.

Ultimately, vacuum annealing is the superior choice when the integrity of the material, both internally and on its surface, is paramount to performance.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Eliminates Oxidation | Bright, clean surface; no post-processing cleaning needed |

| Relieves Internal Stress | Prevents warping; improves dimensional stability |

| Enhances Ductility | Increases workability; reduces risk of cracking |

| Improves Material Consistency | Uniform heating ensures predictable properties |

Ready to enhance your component performance with pristine, oxide-free results?

At KINTEK, we specialize in providing advanced lab equipment, including vacuum furnaces, to meet the precise demands of your laboratory. Our solutions ensure superior material properties, reduced post-processing costs, and consistent results for critical applications in aerospace, medical, and high-purity industries.

Contact us today to discuss how our vacuum annealing expertise can benefit your specific needs.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- What is a vacuum furnace used for? Unlock High-Purity Heat Treatment for Superior Materials