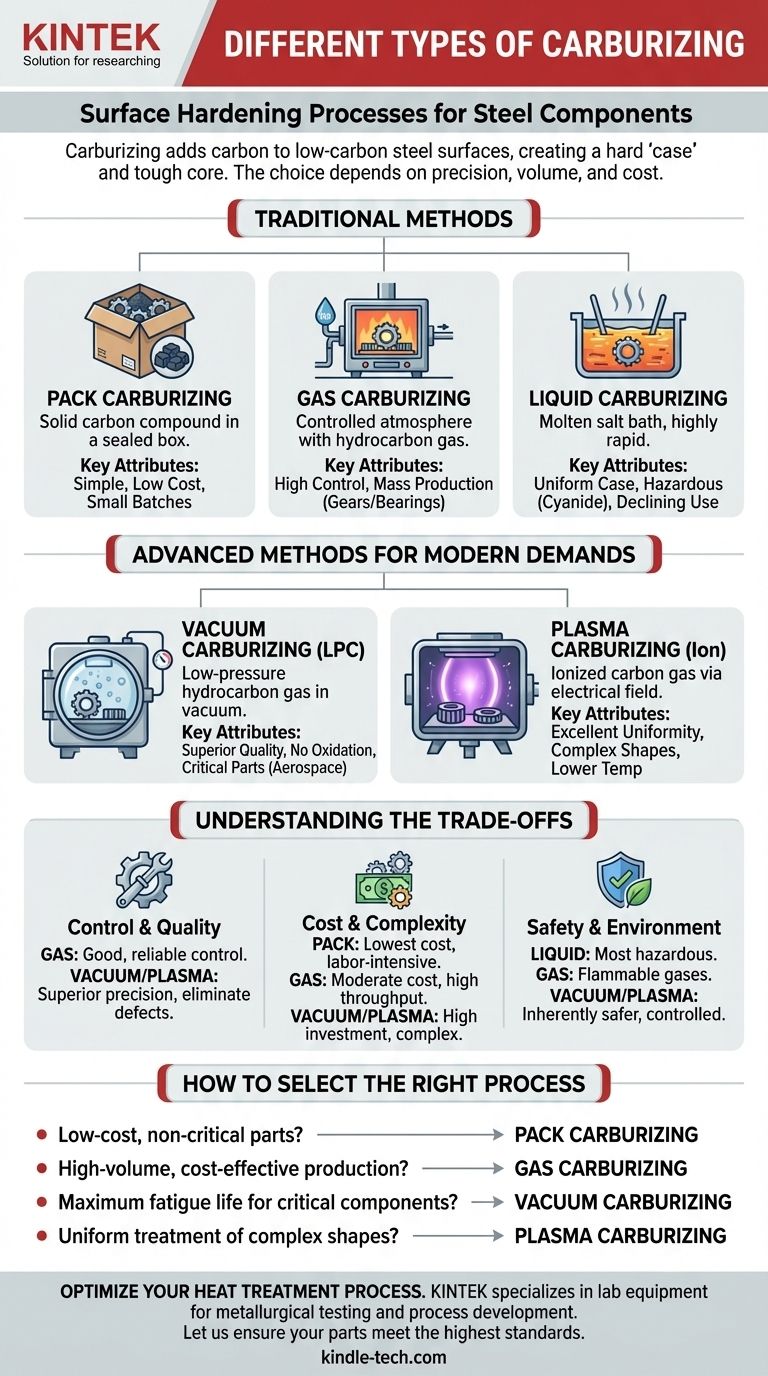

The primary types of carburizing are pack, gas, liquid, vacuum, and plasma carburizing. Each method uses a different medium—solid, gas, liquid salt, or ionized gas—to introduce carbon into the surface of a low-carbon steel part, enabling it to be hardened. The choice of method depends on factors like required precision, production volume, component complexity, and cost.

The core decision in selecting a carburizing process is not about finding the "best" method, but about matching the process capabilities to your specific engineering and economic requirements. While traditional methods are cost-effective for general use, advanced processes offer superior control and metallurgical quality for high-performance applications.

What is Carburizing and Why Is It Used?

Carburizing is a heat treatment process that adds carbon to the surface of low-carbon steel components. This process does not harden the steel directly; rather, it creates a "case," or a surface layer with a higher carbon content.

The part is then quenched (rapidly cooled) and tempered. The high-carbon case becomes extremely hard and wear-resistant, while the low-carbon core remains softer and tougher. This creates a component with an ideal combination of surface durability and core ductility, making it resistant to both wear and catastrophic fracture.

The Traditional Carburizing Methods

These methods have been used for decades and remain relevant for many applications, balancing cost and performance.

Pack Carburizing (Solid Carburizing)

This is the original method. Parts are packed into a sealed steel box, surrounded by a solid, carbon-rich compound like charcoal or coke, along with an "energizer" chemical (e.g., barium carbonate) that promotes the release of carbon monoxide gas.

The box is heated in a furnace for a long period, allowing carbon to slowly diffuse into the steel. It is simple and requires minimal investment, making it suitable for one-off jobs or small-scale operations.

Gas Carburizing

This is the most widely used industrial method today. Parts are loaded into a sealed furnace with a controlled atmosphere. A carbon-rich gas, such as natural gas (methane) or propane, is introduced into the furnace.

At high temperatures, these gases break down, and the liberated carbon is absorbed by the steel surface. This method offers excellent control over case depth and surface carbon concentration, making it highly repeatable and ideal for mass production of components like gears and bearings.

Liquid Carburizing (Salt Bath Carburizing)

In this process, parts are immersed in a molten salt bath operating at high temperatures. The bath contains carbon-releasing compounds, typically sodium cyanide.

Liquid carburizing is very rapid and produces a uniform case, as the liquid contacts all surfaces evenly. However, the use of highly toxic cyanide salts presents significant safety hazards and environmental disposal challenges, causing its use to decline in favor of safer alternatives.

Advanced Carburizing for Modern Demands

These modern processes were developed to overcome the limitations of traditional methods, offering higher quality and precision for critical applications.

Vacuum Carburizing (LPC)

Also known as Low-Pressure Carburizing (LPC), this process takes place in a vacuum furnace. The parts are first heated in a vacuum to clean the surfaces. Then, a precise amount of a hydrocarbon gas (like acetylene) is introduced at very low pressure.

Because there is no oxygen in the furnace, this method completely eliminates intergranular oxidation (IGO), a defect that can reduce the fatigue life of parts hardened by gas carburizing. Vacuum carburizing produces an exceptionally clean, high-quality case and is preferred for high-stress components like aerospace gears.

Plasma Carburizing (Ion Carburizing)

This is the most technologically advanced method. Inside a vacuum chamber, a high-voltage electrical field is applied between the parts (the cathode) and the chamber wall (the anode). This creates a plasma, or "glow discharge," around the parts.

A carbon-bearing gas is introduced, and the plasma ionizes it, causing carbon ions to accelerate and bombard the part's surface. This provides outstanding control over case uniformity, even on highly complex shapes and in blind holes. It can also be performed at lower temperatures, reducing part distortion.

Understanding the Trade-offs

No single process is perfect for every situation. The choice involves balancing cost, quality, and production logistics.

Control and Quality

Gas carburizing offers good, reliable control for most industrial needs. However, vacuum and plasma carburizing provide superior precision and eliminate defects like intergranular oxidation, resulting in a metallurgically cleaner surface with better fatigue performance.

Cost and Complexity

Pack carburizing has the lowest equipment cost but is labor-intensive and difficult to automate. Gas carburizing represents a balance of moderate equipment cost and high throughput. Vacuum and plasma furnaces require a significant capital investment and are more complex to operate, making them best suited for high-value components where performance justifies the cost.

Safety and Environment

Liquid carburizing is the most hazardous due to the toxic cyanide salts. Gas carburizing involves flammable gases and requires robust safety protocols. Vacuum and plasma processes are inherently safer, as they operate in a controlled, enclosed environment and use very small quantities of process gas.

How to Select the Right Carburizing Process

Your final decision should be driven by the specific performance requirements and value of the component you are treating.

- If your primary focus is low-cost, non-critical parts: Pack carburizing is a viable, simple solution for small batches or one-off jobs.

- If your primary focus is high-volume, cost-effective production with good control: Gas carburizing is the industry standard and the most common choice for automotive and industrial parts.

- If your primary focus is maximum fatigue life and performance for critical components: Vacuum carburizing is the superior choice, as its elimination of surface oxidation directly translates to longer service life.

- If your primary focus is uniform treatment of highly complex shapes or special materials: Plasma carburizing offers unmatched control and uniformity, especially for intricate geometries.

Ultimately, aligning the carburizing method with the part's application is the key to achieving optimal performance and economic efficiency.

Summary Table:

| Method | Process Medium | Key Advantage | Best For |

|---|---|---|---|

| Pack Carburizing | Solid Compound | Low Cost | Small Batches, Non-Critical Parts |

| Gas Carburizing | Hydrocarbon Gas | High Volume, Good Control | Automotive & Industrial Parts |

| Liquid Carburizing | Molten Salt Bath | Rapid & Uniform | Declining Use (Safety Concerns) |

| Vacuum Carburizing | Hydrocarbon Gas (Vacuum) | Superior Quality, No Oxidation | Critical, High-Stress Components |

| Plasma Carburizing | Ionized Gas (Plasma) | Excellent Uniformity on Complex Shapes | Intricate Geometries, Special Materials |

Need to Optimize Your Heat Treatment Process?

Choosing the right carburizing method is critical for achieving the desired hardness, wear resistance, and fatigue life in your components. The wrong choice can lead to subpar performance or unnecessary costs.

KINTEK specializes in lab equipment and consumables for metallurgical testing and process development. We can provide the furnaces and analytical tools you need to validate and perfect your carburizing processes, whether you're working with traditional methods or advanced techniques like vacuum and plasma.

Let us help you ensure your parts meet the highest standards of quality and performance.

Contact our experts today to discuss your specific application and how our solutions can bring precision and reliability to your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds