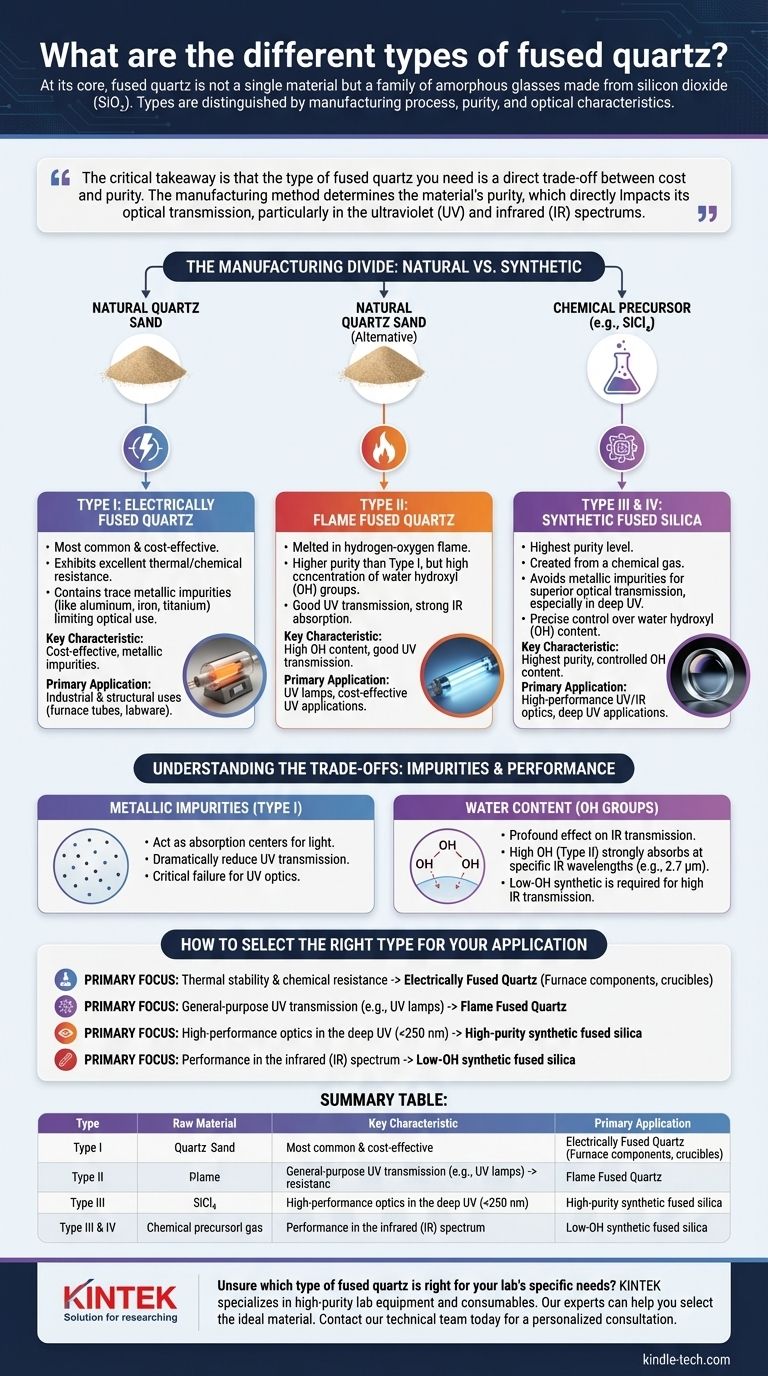

At its core, fused quartz is not a single material but a family of amorphous glasses made from silicon dioxide (SiO₂). The different "types" are primarily distinguished by their manufacturing process, which in turn dictates their level of purity and optical characteristics. The main categories are derived from either natural quartz sand or a chemically synthesized precursor.

The critical takeaway is that the type of fused quartz you need is a direct trade-off between cost and purity. The manufacturing method determines the material's purity, which directly impacts its optical transmission, particularly in the ultraviolet (UV) and infrared (IR) spectrums.

The Manufacturing Divide: Natural vs. Synthetic

The most fundamental way to classify fused quartz is by its raw material source. This single factor has the largest impact on the final product's properties and cost.

Type I: Electrically Fused Quartz

This is the most common and cost-effective type of fused quartz. It is produced by melting high-purity, natural quartz sand in an electric arc furnace.

While it exhibits the excellent thermal and chemical resistance fused quartz is known for, the natural sand contains trace metallic impurities (like aluminum, iron, and titanium). These impurities limit its use in demanding optical applications.

Type II: Flame Fused Quartz

This type is also produced from natural quartz sand, but it is melted in a hydrogen-oxygen flame. This process yields a material with higher purity and fewer metallic impurities than electrically fused quartz.

The key characteristic of flame fusion is a high concentration of water hydroxyl (OH) groups that become trapped in the glass. This results in excellent transmission in the UV spectrum but creates strong absorption bands in the infrared (IR) region.

Type III & IV: Synthetic Fused Silica

This material represents the highest purity level available. Instead of starting with natural sand, synthetic fused silica is created from a chemical gas precursor, most commonly silicon tetrachloride (SiCl₄).

This process avoids the metallic impurities inherent in natural quartz, resulting in superior optical transmission, especially in the deep UV range. The process also allows for precise control over the water hydroxyl (OH) content, leading to distinct sub-types.

Understanding the Trade-offs: Impurities and Performance

The choice between types is rarely about one being "better" in all aspects. It is a calculated decision based on your specific application and the material's inherent properties.

The Impact of Metallic Impurities

Metallic impurities, primarily found in electrically fused quartz (Type I), act as absorption centers for light. This dramatically reduces the material's ability to transmit light in the ultraviolet spectrum.

For applications like furnace tubes, thermocouple sheaths, or general labware, where optical transmission is not the primary concern, this is perfectly acceptable. For UV optics, it is a critical failure point.

The Role of Water Content (OH Groups)

Water hydroxyl (OH) groups have a profound effect on infrared (IR) transmission. Materials with high OH content, like flame fused quartz (Type II), strongly absorb light at specific IR wavelengths, particularly around 2.7 µm.

Synthetic fused silica can be manufactured to be "low-OH" or "high-OH." A high-OH grade offers excellent deep UV performance, while a low-OH grade is specifically engineered for applications requiring high transmission across the near-infrared spectrum.

Cost as the Deciding Factor

The manufacturing complexity directly correlates with cost. Electrically fused quartz is the most economical option for industrial and structural use.

Flame fused quartz occupies a middle ground, offering a good balance of UV performance and cost. Synthetic fused silica is the most expensive due to the high-purity chemical processes involved, reserving it for applications where its exceptional optical quality is non-negotiable.

How to Select the Right Type for Your Application

Choosing the correct material requires matching its properties to your primary goal.

- If your primary focus is thermal stability and chemical resistance: Electrically fused quartz offers the essential benefits for furnace components, crucibles, and rods at the lowest cost.

- If your primary focus is general-purpose UV transmission (e.g., UV lamps): Flame fused quartz provides a cost-effective solution with good performance in the near-UV spectrum.

- If your primary focus is high-performance optics in the deep UV (<250 nm): High-purity synthetic fused silica is the only choice to ensure maximum light transmission.

- If your primary focus is performance in the infrared (IR) spectrum: A low-OH synthetic fused silica is necessary to avoid the absorption bands caused by water content.

By understanding how manufacturing dictates purity and performance, you can confidently select the precise type of fused quartz that meets both your technical and budgetary requirements.

Summary Table:

| Type | Raw Material | Key Characteristic | Primary Application |

|---|---|---|---|

| Type I: Electrically Fused | Natural Quartz Sand | Cost-effective, contains metallic impurities | Industrial & structural uses (furnace tubes, labware) |

| Type II: Flame Fused | Natural Quartz Sand | High OH content, good UV transmission | UV lamps, cost-effective UV applications |

| Type III & IV: Synthetic Fused Silica | Chemical Precursor (e.g., SiCl₄) | Highest purity, controlled OH content | High-performance UV/IR optics, deep UV applications |

Unsure which type of fused quartz is right for your lab's specific needs? KINTEK specializes in high-purity lab equipment and consumables, including fused quartz components for demanding thermal and optical applications. Our experts can help you select the ideal material based on your requirements for UV/IR transmission, thermal stability, and budget.

Contact our technical team today for a personalized consultation and ensure optimal performance for your laboratory processes.

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- Why is a laboratory electric thermostatic drying oven used at 120°C? Protect Your Fe2O3–CeO2 Nanocomposites

- What is the principle of Rotavapor? Master Gentle Solvent Removal for Heat-Sensitive Samples

- Why is a high-purity quartz tube necessary for CO2 and methane separation? Key Role in Plasma DBD Stability

- Why is a K-type thermocouple thermometer necessary for plasma treatment? Ensure Safety in Biological Material Processing

- Why is tantalum foil required when using graphite molds for sintering yttrium oxide? Ensure Optical Purity

- Why refractory materials are used in furnaces? Ensure Safety, Efficiency, and Process Purity

- Significance of Grinding Ball Sizes and Ratios for ODS Steel? Optimize Your Milling Process for Superior Alloying

- What is refractory material made of? Key Components for Extreme Heat Resistance