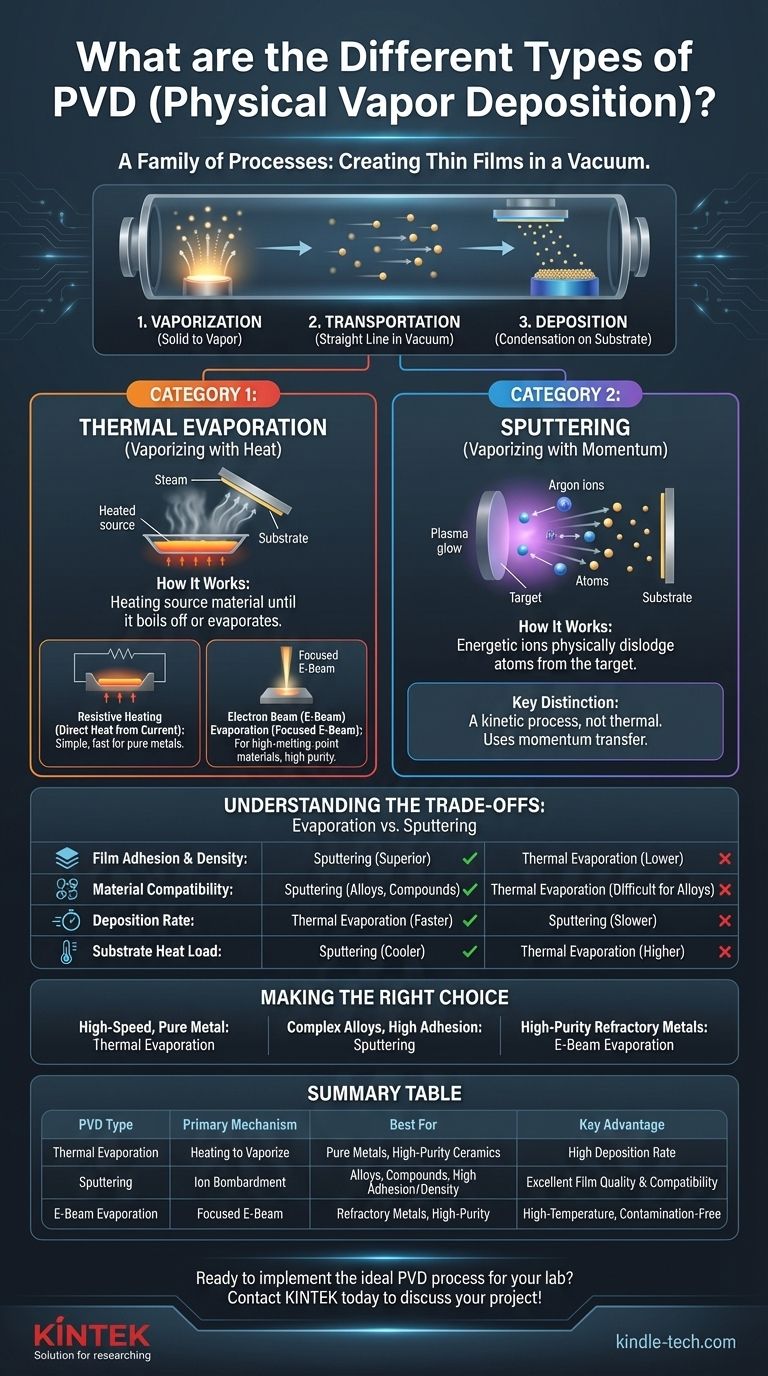

At its core, Physical Vapor Deposition (PVD) is not a single technique but a family of processes. The primary types of PVD are categorized by the method used to transform the solid coating material into a vapor. The two fundamental categories are Thermal Evaporation, which uses heat to vaporize the material, and Sputtering, which uses energetic ion bombardment to physically eject material.

The critical distinction between PVD methods lies in how they create the vapor. Choosing the right process depends entirely on the material you need to deposit and the final film properties you need to achieve, such as adhesion, density, and purity.

The Unifying Principle: From Solid to Vapor

All PVD processes occur inside a vacuum chamber and share three fundamental steps. The "type" of PVD is defined entirely by the first step.

1. Vaporization

This is the defining stage. A source material, known as a "target," is converted from a solid into a vapor. The method used here dictates the energy of the vapor particles and the overall characteristics of the process.

2. Transportation

Once vaporized, the atoms or molecules travel in a straight line through the low-pressure vacuum environment, experiencing few or no collisions with background gas molecules.

3. Deposition

The vapor stream comes into contact with the cooler substrate (the object being coated) and condenses on its surface, forming a thin, solid film.

Category 1: Thermal Evaporation (Vaporizing with Heat)

Thermal evaporation is conceptually the simplest PVD method. The source material is heated in a vacuum until its surface atoms gain enough thermal energy to "boil off" or evaporate.

How It Works

Think of boiling a pot of water. The water turns to steam (vapor), which will condense on a cool surface held above it, like a lid. Thermal evaporation works on the same principle but with solid materials in a vacuum.

Sub-Type: Resistive Heating

This is the most straightforward evaporation technique. The source material is placed in a high-resistance container, often called a "boat," made of a material like tungsten. A high electrical current is passed through this boat, causing it to heat up rapidly and, in turn, heat and evaporate the source material.

Sub-Type: Electron Beam (E-Beam) Evaporation

For materials with very high melting points (like ceramics or refractory metals), resistive heating is insufficient. E-beam evaporation uses a high-energy beam of electrons, guided by magnetic fields, to directly strike and heat the source material, causing localized boiling and evaporation.

Category 2: Sputtering (Vaporizing with Momentum)

Sputtering is a kinetic process, not a thermal one. It uses momentum transfer from energetic ions to dislodge atoms from the target material.

How It Works

The process starts by introducing an inert gas, typically Argon, into the vacuum chamber. A strong electric field is applied, which ionizes the gas and creates a glowing plasma. These positive Argon ions are then accelerated into the negatively charged target material with tremendous force.

When the ions strike the target, they act like atomic-scale billiard balls, physically knocking out or "sputtering" atoms from the target's surface. These ejected atoms then travel to the substrate and form a coating.

Understanding the Trade-offs: Evaporation vs. Sputtering

Neither method is universally superior; they are suited for different goals.

Film Adhesion and Density

Sputtered atoms are ejected with much higher kinetic energy than evaporated atoms. This high energy helps them form a denser, more adherent film when they embed into the substrate surface. Winner: Sputtering.

Material Compatibility

Thermal evaporation works best for single-element metals with relatively low melting points. It is difficult to evaporate alloys because the element with the lower boiling point will vaporize first. Sputtering physically ejects whatever is on the target surface, making it excellent for depositing alloys, compounds, and mixtures with precise control. Winner: Sputtering.

Deposition Rate

Thermal evaporation is generally a much faster deposition process, capable of building thicker films in less time. Sputtering is a slower, more controlled process. Winner: Thermal Evaporation.

Substrate Heat Load

The intense heating in thermal evaporation radiates a significant amount of heat, which can damage heat-sensitive substrates like plastics. Sputtering is considered a "cooler" process in terms of radiant heat, making it safer for delicate components. Winner: Sputtering.

Making the Right Choice for Your Application

Selecting the correct PVD process requires matching the process capabilities to your application's specific needs.

- If your primary focus is high-speed deposition of a pure metal: Thermal evaporation, particularly resistive heating, is the most direct and efficient choice.

- If your primary focus is depositing complex alloys, compounds, or achieving maximum film adhesion and density: Sputtering provides the superior control and film quality required for these demanding applications.

- If your primary focus is depositing high-purity refractory metals or ceramics: Electron-beam evaporation is the ideal method, as it can reach the necessary temperatures without contaminating the source material.

Ultimately, understanding the fundamental vaporization mechanism is the key to selecting the PVD process that will deliver the results you need.

Summary Table:

| PVD Type | Primary Mechanism | Best For | Key Advantage |

|---|---|---|---|

| Thermal Evaporation | Heating the source material to vaporize it | High-speed deposition of pure metals, high-purity ceramics | High deposition rate |

| Sputtering | Energetic ion bombardment to eject target atoms | Alloys, compounds, high adhesion/density films | Excellent film quality and material compatibility |

| E-Beam Evaporation | Focused electron beam for localized heating | Refractory metals, high-purity materials | High-temperature capability without contamination |

Ready to implement the ideal PVD process for your lab? The choice between Thermal Evaporation and Sputtering is critical for achieving the right film properties, whether you need high-speed deposition, superior adhesion, or compatibility with complex materials. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific PVD needs.

Our experts can help you select the perfect system to ensure optimal results for your research or production. Contact us today to discuss your project and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation