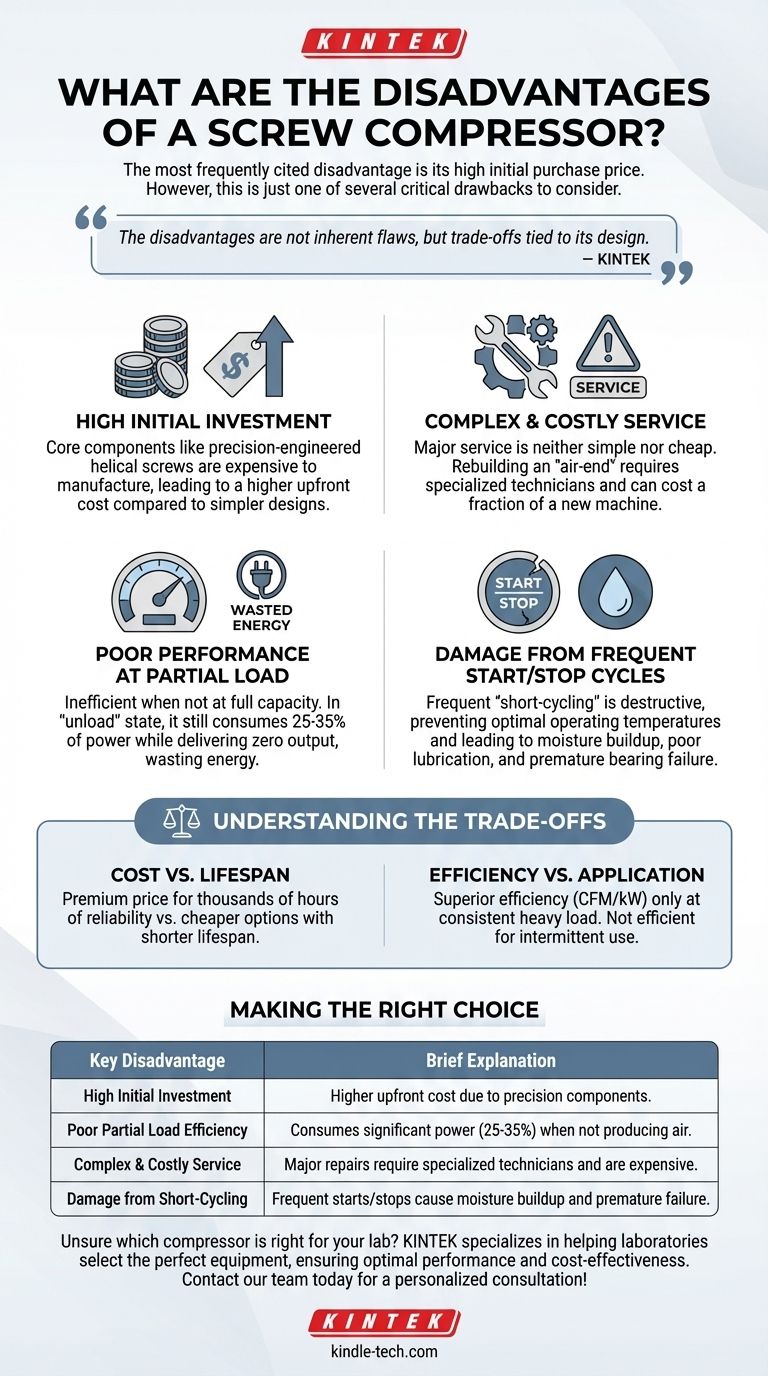

The most frequently cited disadvantage of a rotary screw compressor is its high initial purchase price. While this cost can often be justified by superior efficiency and a longer operational lifespan in the right environment, it represents a significant capital barrier. However, the financial investment is only one of several critical drawbacks that must be evaluated against your specific operational needs.

The disadvantages of a screw compressor are not inherent flaws, but rather trade-offs tied to its design. Its high initial cost and lower efficiency at partial loads are the price paid for its exceptional performance and reliability in continuous, high-demand applications.

The Financial Equation: Beyond the Sticker Price

The most obvious disadvantage is financial, but it extends beyond the initial purchase. The total cost of ownership involves both the acquisition price and long-term maintenance realities.

High Initial Investment

A rotary screw compressor's core components—two precision-engineered helical screws (rotors) that must mesh with extremely tight tolerances—are expensive to manufacture. This advanced engineering directly translates to a higher upfront cost compared to simpler designs like piston compressors.

For new businesses or operations with limited capital, this initial expense can be a significant hurdle, forcing them to consider less-than-ideal alternatives.

Complex and Costly Service

While known for their reliability, when major service is required, it is neither simple nor cheap. Rebuilding a failed "air-end" (the unit containing the rotors) is a specialized task that demands trained technicians and can cost a substantial fraction of a new machine.

This contrasts sharply with piston compressors, where common wear items like rings and valves can often be replaced by a mechanically competent individual.

Operational Inefficiencies in the Wrong Environment

A screw compressor's greatest strengths can become its greatest weaknesses if it is used outside of its intended operating parameters. Its design is optimized for continuous, full-load operation.

Poor Performance at Partial Load

Screw compressors are notoriously inefficient when they are not running at or near their full capacity. When air demand is low, a fixed-speed machine will enter an "unload" state, where it continues to run but does not produce compressed air.

During this unload cycle, the compressor still consumes a significant amount of power (often 25-35% of its full-load draw) while delivering zero output. For facilities with highly variable air demand, this results in substantial wasted energy.

Damage from Frequent Start/Stop Cycles

Using a screw compressor for intermittent tasks that cause frequent starts and stops (known as "short-cycling") can be destructive. Each startup cycle is hard on electrical and mechanical components.

More importantly, short-cycling prevents the machine from reaching its optimal operating temperature. This allows moisture from the air to condense within the lubricant, leading to poor lubrication, corrosion, and premature failure of the critical rotor bearings.

Understanding the Trade-offs

To make an informed decision, you must view these disadvantages as trade-offs against the machine's intended purpose.

Cost vs. Lifespan

You pay a premium for a machine designed to run for tens of thousands of hours with high reliability. A cheaper reciprocating compressor, if subjected to the same continuous 24/7 duty cycle, would likely fail much sooner and require more frequent maintenance.

Efficiency vs. Application

The superior efficiency (CFM per kW) of a screw compressor is only realized when it is properly sized and running under a consistent, heavy load. For a small workshop or garage with intermittent air needs, a piston compressor will almost always be more energy-efficient and cost-effective overall.

Simplicity vs. Continuous Duty

A piston compressor is mechanically simple but loud, vibrates, and injects more oil into the air. A screw compressor is a complex, sophisticated machine that provides a smooth, cool, and clean supply of air, making it ideal for continuous industrial applications where air quality and uptime are paramount.

Making the Right Choice for Your Goal

Evaluate your specific application against these trade-offs to determine the correct path forward.

- If your primary focus is minimizing upfront cost for intermittent use: A piston compressor is almost always the more practical and economical choice.

- If your primary focus is running a production line or tool continuously for 8+ hours a day: The higher initial cost of a screw compressor is justified by its long-term reliability and efficiency at high load.

- If your primary focus is dealing with highly variable air demand: A screw compressor with a Variable Speed Drive (VSD) is the best solution to maintain efficiency, but be prepared for the highest initial investment.

Ultimately, understanding these disadvantages prevents a costly mismatch between the tool and the task.

Summary Table:

| Key Disadvantage | Brief Explanation |

|---|---|

| High Initial Investment | Higher upfront cost due to precision-engineered components. |

| Poor Partial Load Efficiency | Consumes significant power (25-35%) even when not producing air. |

| Complex & Costly Service | Major repairs require specialized technicians and are expensive. |

| Damage from Short-Cycling | Frequent starts/stops cause moisture buildup and premature failure. |

Unsure which compressor type is right for your lab's specific operational needs? The trade-offs between initial cost, long-term efficiency, and application requirements are critical. At KINTEK, we specialize in helping laboratories select the perfect equipment, from compressors to a full range of lab essentials, ensuring optimal performance and cost-effectiveness. Let our experts guide you to the ideal solution for your unique demands. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What are some challenges of using waste biomass for energy? Navigating Logistics, Cost, and Efficiency Hurdles

- What is solid state sintering? A Guide to High-Purity Material Consolidation

- Is glass made by sintering? The Truth About How Glass is Formed

- Why is a continuous flow of high-purity nitrogen required during the catalytic pyrolysis of plastics? Maximize Fuel Yield

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- What is the difference between extruded and isostatic graphite? Choose the Right Material for Your Application

- What is the process of sintering steel industry? Optimize Blast Furnace Efficiency with Engineered Feed

- What temperature ranges do scientific laboratory and pharmacy freezers typically control? A Guide to Sample Integrity