At first glance, ceramic restorations seem like an ideal solution, but their primary disadvantages are their potential for brittleness, higher cost compared to traditional materials, and the risk of wearing down opposing natural teeth. While modern ceramics have improved significantly, these core trade-offs remain critical factors in any treatment decision.

The core issue is that the exceptional aesthetics and biocompatibility of ceramic materials come at a price. This price is not just financial but also involves a trade-off in mechanical properties, requiring careful consideration of the restoration's location, the patient's bite, and long-term performance expectations.

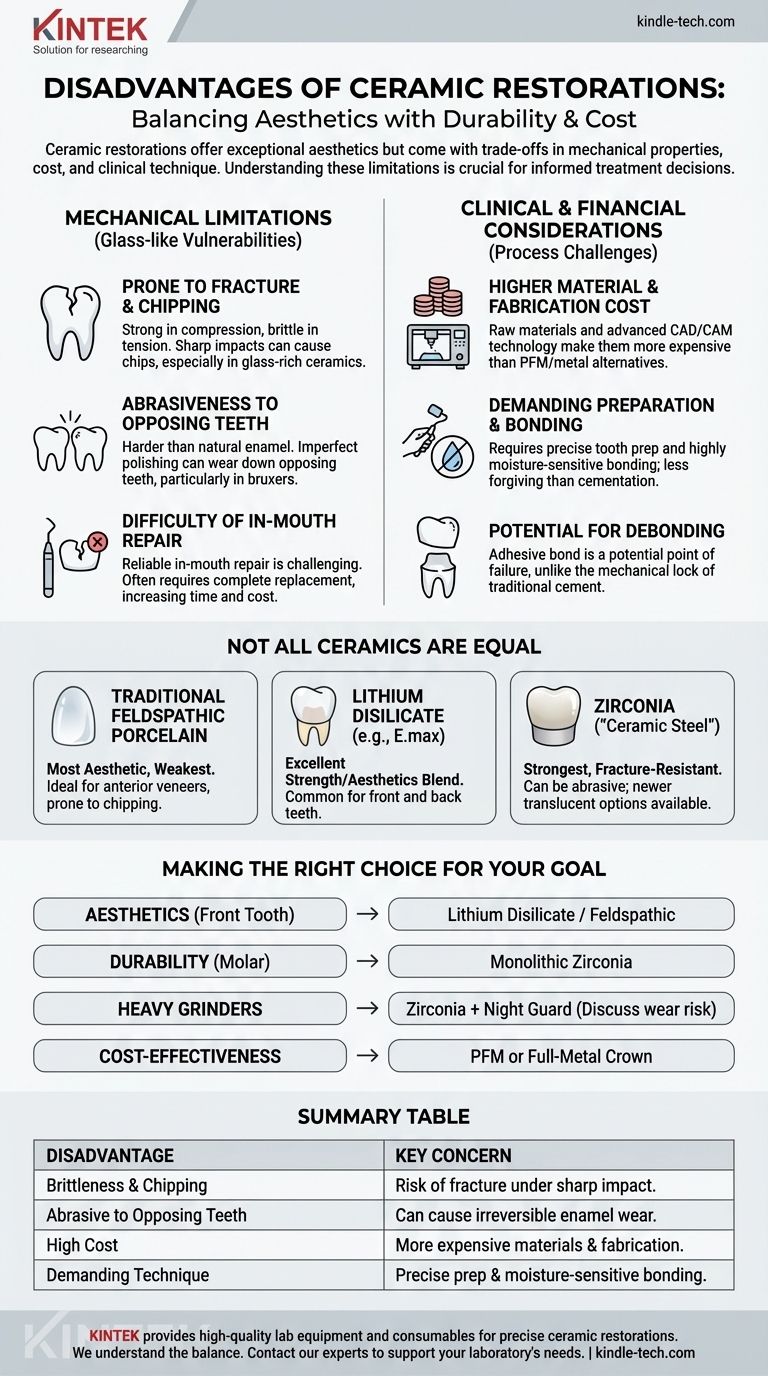

The Mechanical Limitations of Ceramic

While strong under compression, the glass-like nature of many ceramics introduces specific mechanical vulnerabilities that are crucial to understand.

Prone to Fracture and Chipping

Ceramic is exceptionally strong when being pushed on (compressive strength) but can be brittle when pulled or twisted (tensile strength).

This means a sharp, hard impact—like biting down on an olive pit—can cause a chip or fracture. This is a greater risk for more aesthetic, glass-rich ceramics than for high-strength zirconia.

Abrasiveness to Opposing Teeth

Some ceramic materials are harder than natural tooth enamel. If the ceramic surface is not perfectly polished and maintained, it can act like fine sandpaper.

Over time, this can cause significant and irreversible wear on the natural teeth that bite against the restoration. This is a major consideration, especially for patients who grind their teeth (bruxism).

Difficulty of In-Mouth Repair

If a metal or porcelain-fused-to-metal (PFM) crown chips, a dentist can sometimes smooth or repair it in the mouth.

Chipped ceramic is far more difficult to repair reliably. A composite bonding repair is often a temporary fix, and in many cases, the entire restoration must be replaced, incurring additional time and expense.

Clinical and Financial Considerations

Beyond the physical properties of the material itself, the process of creating and placing a ceramic restoration involves its own set of challenges.

Higher Material and Fabrication Cost

All-ceramic restorations are consistently more expensive than PFM or full-metal alternatives.

This cost is driven by the price of the raw materials and the sophisticated technology, such as CAD/CAM milling machines, required for their fabrication.

Demanding Preparation and Bonding Technique

Placing a ceramic restoration is less forgiving than cementing a traditional metal one. The success of the restoration depends heavily on the dentist's skill.

The tooth must be prepared to precise specifications, and the bonding process is highly sensitive to moisture contamination. An imperfect bond can lead to premature failure.

Potential for Debonding

While modern bonding agents are excellent, the adhesive bond between the ceramic and the tooth is a potential point of failure.

This risk, though small, is one that doesn't exist with traditional crowns that are held in place with dental cement, which forms a mechanical lock.

Not All Ceramics Are Created Equal

It is a critical mistake to think of "ceramic" as a single material. The disadvantages vary significantly depending on the specific type used.

Traditional Feldspathic Porcelain

This is the most aesthetically beautiful and translucent ceramic, making it ideal for veneers on front teeth. However, it is also the weakest and most prone to chipping.

Lithium Disilicate (e.g., E.max)

This material offers an excellent blend of strength and aesthetics. It is much stronger than feldspathic porcelain and is a common choice for crowns on both front and back teeth, but it is not as fracture-proof as zirconia.

Zirconia ("Ceramic Steel")

Zirconia is the strongest ceramic available and is extremely resistant to fracture. Its primary disadvantage has traditionally been its opaque, less natural appearance, though newer translucent zirconia options have improved this significantly. Its hardness still poses a risk of wear to opposing teeth if not perfectly polished.

Making the Right Choice for Your Goal

Understanding these disadvantages is not meant to discourage the use of ceramics, but to empower you to have a more informed discussion with your dental professional.

- If your primary focus is aesthetics for a front tooth: A lithium disilicate or even a feldspathic porcelain restoration may be the best choice, accepting the small risk of fracture for the superior cosmetic result.

- If your primary focus is durability for a molar: A monolithic zirconia crown is an excellent option that minimizes the risk of fracture, making it suitable for heavy chewing forces.

- If you are a heavy teeth grinder: Zirconia's strength is a major advantage, but you must discuss managing the risk of wear to your opposing teeth with your dentist, potentially with a night guard.

- If your primary focus is cost-effectiveness: A porcelain-fused-to-metal (PFM) or full-metal crown remains a durable and clinically proven alternative, though with its own aesthetic compromises.

Ultimately, the ideal dental restoration is a careful balance of material science, clinical needs, and personal priorities.

Summary Table:

| Disadvantage | Key Concern |

|---|---|

| Brittleness & Chipping | Risk of fracture under sharp impact, especially with glass-rich ceramics. |

| Abrasive to Opposing Teeth | Can cause irreversible wear on natural enamel if not perfectly polished. |

| High Cost | More expensive than PFM or metal crowns due to materials and fabrication. |

| Demanding Technique | Requires precise tooth preparation and bonding, sensitive to moisture. |

Choosing the right dental restoration is a critical decision. At KINTEK, we understand the delicate balance between aesthetics, durability, and cost. Our high-quality lab equipment and consumables are trusted by dental professionals to fabricate precise and reliable ceramic restorations, ensuring optimal patient outcomes. Whether you're working with zirconia, lithium disilicate, or feldspathic porcelain, KINTEK provides the tools you need for success. Have questions about materials or techniques? Contact our experts today to discuss how we can support your laboratory's needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is pre sintered zirconia? The Key to Milling Strong, Precise Dental Restorations

- What are the characteristics of dental ceramics? Achieve Superior Esthetics and Durability

- What is the strength of dental porcelain? A Guide to Durability and Aesthetics

- What is the furnace in which ceramics are fired? A Guide to Choosing the Right Kiln for Your Project

- Why is ceramic used in dentistry? For Aesthetic, Biocompatible, and Durable Restorations

- What are the advantages of zirconia bridges? A Durable, Metal-Free Solution for a Natural Smile

- What temperature do you fire zirconia? Master the Sintering Cycle for Peak Strength & Aesthetics

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency