While widely used for high-quality graphene, the Chemical Vapor Deposition (CVD) method has significant operational and environmental drawbacks. The process requires high temperatures that can damage many substrates, involves highly toxic and dangerous chemical precursors, and generates corrosive by-products that are difficult and costly to neutralize.

The primary challenge of CVD graphene isn't its quality, but the demanding process required to achieve it. While it produces the large-area, high-purity films necessary for industrial applications, it comes with significant costs related to energy, safety protocols, and waste management.

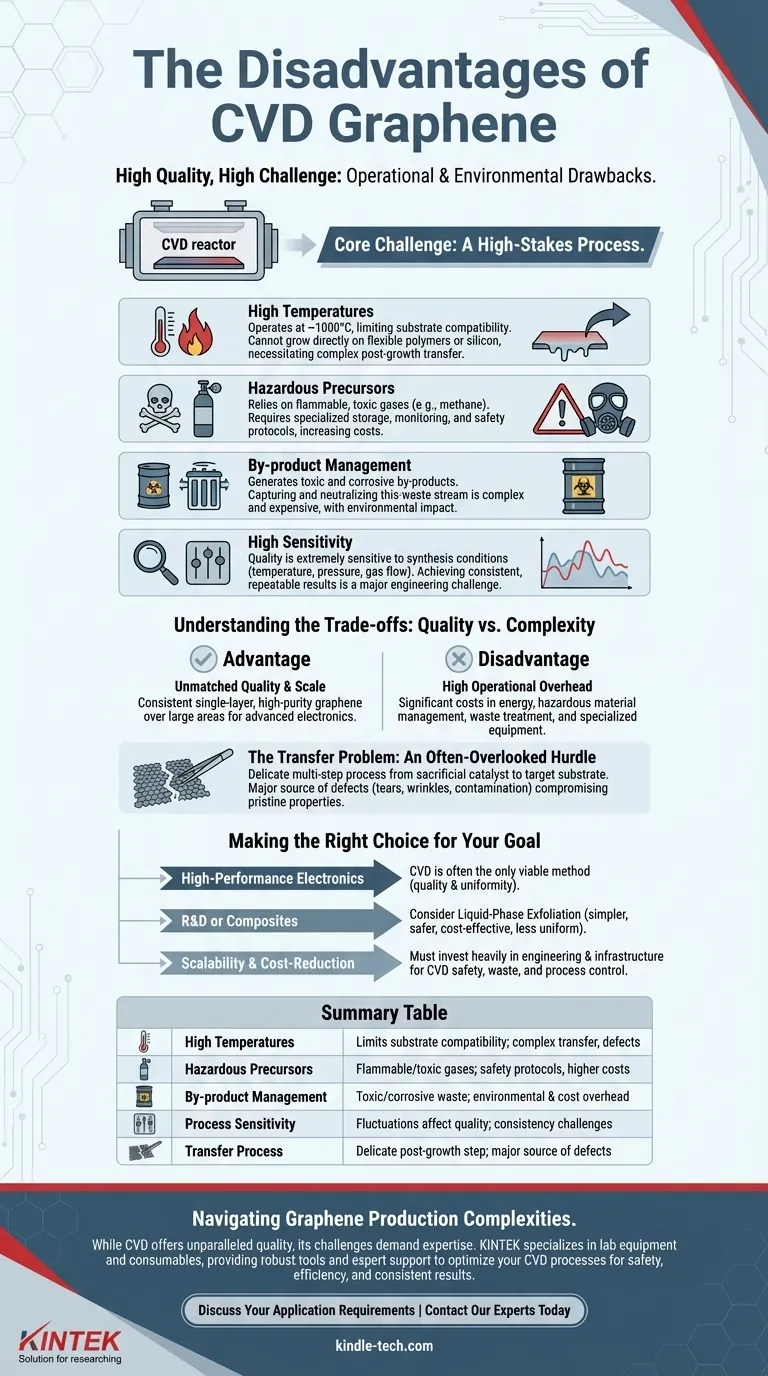

The Core Challenge: A High-Stakes Process

CVD is the dominant method for producing the uniform, large-area graphene sheets required for advanced electronics. However, the path to achieving this quality is laden with practical and financial obstacles.

High Temperatures Limit Substrate Compatibility

The CVD process typically operates at very high temperatures, often around 1000°C. This heat is necessary to catalyze the reaction that forms graphene on a metal substrate, like copper or nickel.

This thermal requirement makes it impossible to grow graphene directly onto many materials, such as flexible polymers or silicon wafers, which cannot withstand such heat. This necessitates a post-growth transfer step, which introduces its own set of problems.

Hazardous and Expensive Precursors

CVD relies on precursor gases, such as methane, to supply the carbon atoms for the graphene film. These precursors are often flammable, toxic, and require high vapor pressure.

Handling these materials safely requires specialized storage, monitoring equipment, and facility-wide safety protocols, which significantly increases the capital and operational cost of production.

The Problem of By-product Management

The chemical reactions within a CVD chamber are not perfectly efficient. They produce toxic and corrosive by-products that must be captured and neutralized.

This waste stream presents a significant environmental and cost challenge. Managing these by-products in a responsible way is a complex and expensive process, especially at an industrial scale.

High Sensitivity to Process Conditions

The final quality of CVD graphene is extremely sensitive to a range of synthesis conditions.

Minor fluctuations in temperature, pressure, gas flow rates, or even the surface roughness of the catalyst substrate can dramatically impact the nucleation and growth of the film. This makes achieving consistent, repeatable results a major engineering challenge.

Understanding the Trade-offs: Quality vs. Complexity

The decision to use CVD graphene hinges on a clear understanding of what you gain versus what you must invest. It is a classic trade-off between final product quality and process complexity.

Advantage: Unmatched Quality and Scale

No other method consistently produces single-layer graphene with such high purity and uniformity over large areas. CVD allows for precise control over the number of layers, making it the premier choice for applications like transparent conductive films and advanced sensors.

Disadvantage: High Operational Overhead

The combined costs of high energy consumption, hazardous material management, waste treatment, and specialized equipment create a high barrier to entry. These factors represent a significant portion of the final cost of the graphene film.

The Transfer Problem: An Often-Overlooked Hurdle

Because graphene is grown on a sacrificial metal catalyst, it must be transferred to the final target substrate. This multi-step transfer process is delicate and a major source of defects.

During transfer, the graphene film can be torn, wrinkled, or contaminated with residues. This can compromise the pristine electrical and mechanical properties that made CVD graphene desirable in the first place, negating some of its primary advantages.

Making the Right Choice for Your Goal

The disadvantages of CVD are significant, but they must be weighed against its unique capabilities. Your specific application will determine if the trade-offs are acceptable.

- If your primary focus is high-performance electronics: CVD is often the only viable method, as it provides the necessary film quality and uniformity over large areas.

- If your primary focus is R&D or composites: Other methods like liquid-phase exfoliation may be simpler, safer, and more cost-effective, even if the graphene quality is less uniform.

- If your primary focus is scalability and cost-reduction: You must be prepared to invest heavily in the engineering and infrastructure required to manage the safety, waste, and process control demands of CVD.

Ultimately, choosing CVD is a strategic decision that trades process complexity and high operational costs for unparalleled material quality and scale.

Summary Table:

| Disadvantage | Key Challenge | Impact on Production |

|---|---|---|

| High Temperatures | Limits substrate compatibility | Requires complex transfer process, introduces defects |

| Hazardous Precursors | Flammable, toxic gases (e.g., methane) | Increases safety protocols and operational costs |

| By-product Management | Toxic and corrosive waste | Adds significant environmental and cost overhead |

| Process Sensitivity | Minor fluctuations affect quality | Challenges in achieving consistent, repeatable results |

| Transfer Process | Delicate post-growth step | Major source of defects, compromising final properties |

Navigating the complexities of graphene production requires the right partner.

While CVD graphene offers unparalleled quality for advanced electronics, its production challenges—from high-temperature constraints to hazardous material handling—demand specialized expertise and reliable equipment.

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories developing next-generation materials. We provide the robust tools and expert support necessary to manage complex processes like CVD, helping you optimize for safety, efficiency, and consistent results.

Let's discuss your specific application requirements. Contact our experts today via our Contact Form to explore how our solutions can help you overcome the hurdles of high-quality graphene production.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance