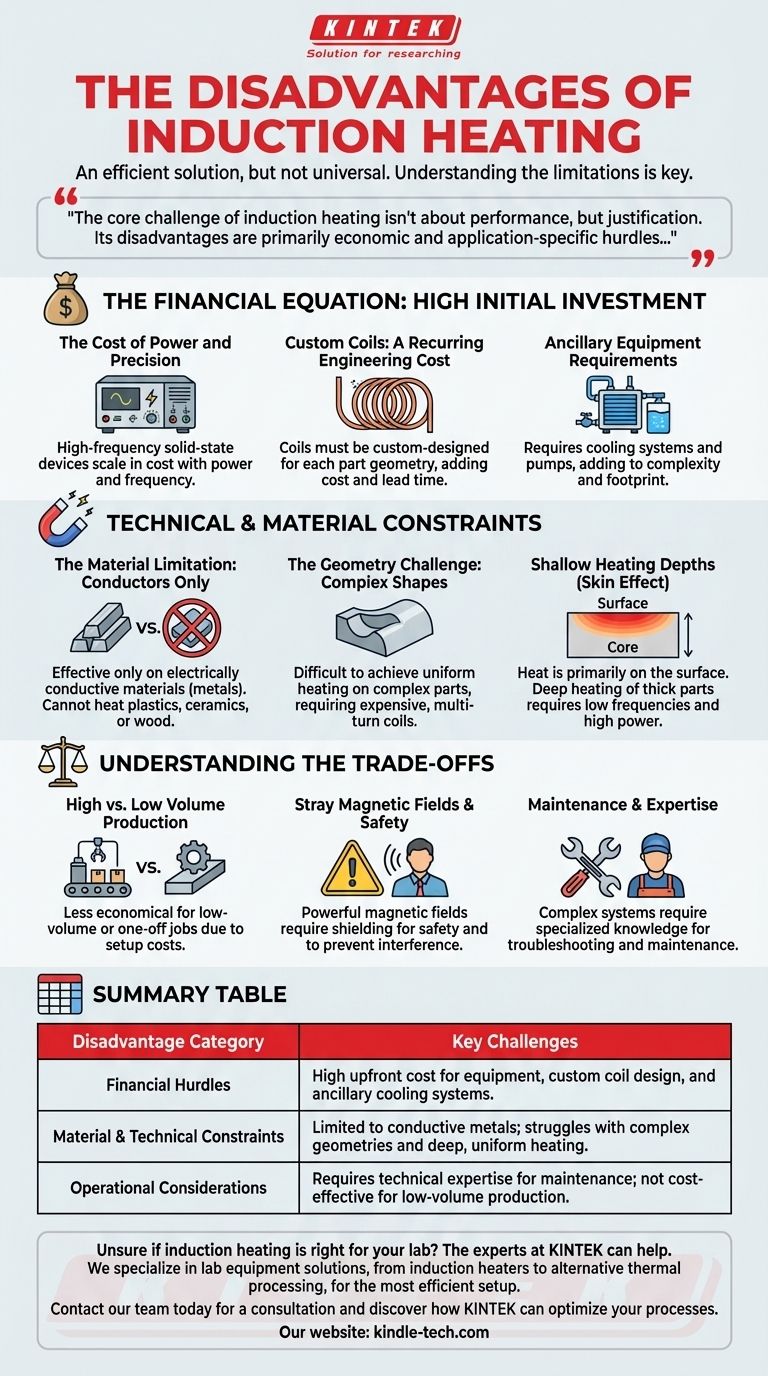

While incredibly efficient and precise, induction heating is not a universal solution. Its primary disadvantages are the significant initial capital investment required for equipment, the complexity and cost associated with designing custom coils for specific applications, and its fundamental limitation to only heating electrically conductive materials.

The core challenge of induction heating isn't about performance, but justification. Its disadvantages are primarily economic and application-specific hurdles that must be weighed against its undeniable benefits in speed, control, and efficiency for the right use case.

The Financial Equation: High Initial Investment

Induction heating systems represent a significant upfront cost compared to many traditional heating methods like furnaces or torches. This cost is a major factor in determining its viability for a given operation.

The Cost of Power and Precision

The power supply, or inverter, is the heart of an induction system. These are sophisticated solid-state devices that convert line-frequency AC power into the high-frequency AC current needed to generate the magnetic field, and their cost scales directly with their power output and frequency range.

Custom Coils: A Recurring Engineering Cost

The induction coil is not a one-size-fits-all component. It must be carefully designed and fabricated to match the specific geometry of the part being heated to ensure efficient and uniform energy transfer.

This custom engineering adds significant cost and lead time, especially for operations that handle a wide variety of parts.

Ancillary Equipment Requirements

Beyond the power supply and coil, a complete induction system requires a cooling system, typically using water, to dissipate heat from the coil and electronics. This adds to the initial capital outlay, installation complexity, and physical footprint of the equipment.

Technical and Material Constraints

Beyond the financial considerations, induction heating has inherent physical limitations that make it unsuitable for certain materials and applications.

The Material Limitation: Conductors Only

Induction heating works by inducing electrical currents within the material itself. Therefore, it is only effective on materials that are electrically conductive, such as metals like steel, copper, and aluminum.

It cannot be used to directly heat non-conductive materials like plastics, ceramics, glass, or wood.

The Geometry Challenge: Complex Shapes

Achieving uniform heating on parts with complex geometries, sharp corners, or deep recesses can be extremely difficult. The magnetic field's strength decreases with distance, leading to potential hot and cold spots if the coil cannot be perfectly coupled to the entire surface.

This often requires highly complex, multi-turn coils that are expensive to design and build.

Shallow Heating Depths (Skin Effect)

The induced current tends to flow on the surface of the workpiece, a phenomenon known as the skin effect. While this is a major advantage for surface hardening, it can be a disadvantage when the goal is to heat the entire volume of a very large or thick part.

Achieving deep, uniform heating in large cross-sections requires very low frequencies and high power, which drives up equipment cost and heating time.

Understanding the Trade-offs

The disadvantages of induction heating are best understood as trade-offs for its unique advantages. The key is to recognize when these trade-offs are acceptable.

High vs. Low Volume Production

The high setup costs for equipment and custom coils make induction heating less economical for one-off jobs or low-volume production runs.

However, for high-volume, repeatable processes like in automotive or aerospace manufacturing, the initial cost is quickly offset by high throughput, low energy consumption per part, and superior quality control.

Stray Magnetic Fields and Safety

Induction systems generate powerful magnetic fields. Proper design and shielding are critical to ensure the safety of personnel (especially those with medical implants) and to prevent interference with nearby sensitive electronic equipment.

Maintenance and Expertise

Induction heaters are complex electronic systems. Troubleshooting and maintaining them requires a higher level of technical skill and specialized knowledge compared to a simple resistance furnace, potentially impacting maintenance costs and downtime.

Is Induction Heating the Right Choice for You?

Evaluating these disadvantages against your specific goals is the most critical step.

- If your primary focus is high-volume, repeatable manufacturing of metal parts: The initial investment is often justified by superior speed, energy efficiency, and process control in the long run.

- If you work with diverse, low-volume, or one-off parts: The recurring cost and time for custom coil design may make more flexible heating methods, like a furnace, more practical.

- If your application requires heating non-conductive materials: Induction heating is fundamentally unsuitable, and you must consider alternative technologies like convection, infrared, or dielectric heating.

- If you need to through-heat very large, thick metal objects: Carefully evaluate whether a traditional furnace is more time and cost-effective than a very high-power, low-frequency induction system.

Understanding these limitations is the key to leveraging induction heating's power where it delivers the most value.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Financial Hurdles | High upfront cost for equipment, custom coil design, and ancillary cooling systems. |

| Material & Technical Constraints | Limited to conductive metals; struggles with complex geometries and deep, uniform heating. |

| Operational Considerations | Requires technical expertise for maintenance; not cost-effective for low-volume production. |

Unsure if induction heating is right for your lab's specific metalworking needs? The experts at KINTEK can help you weigh the pros and cons. We specialize in providing the right lab equipment solutions, from induction heaters to alternative thermal processing systems, ensuring you get the most efficient and cost-effective setup for your application. Contact our team today for a personalized consultation and discover how KINTEK can optimize your laboratory's heating processes.

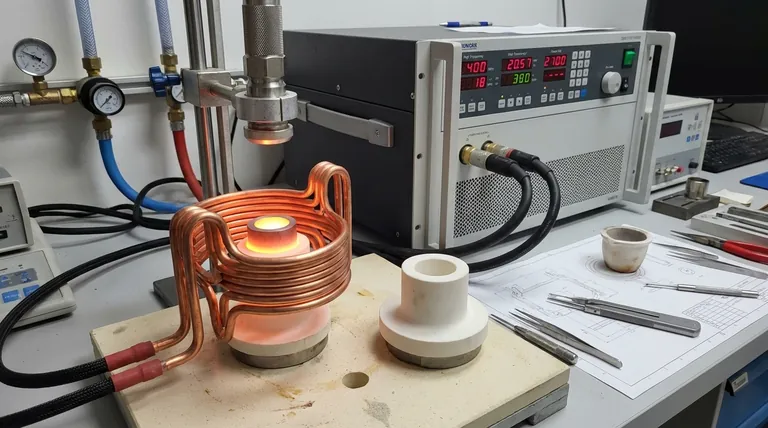

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- What is the thermal expansion coefficient of molybdenum disilicide? Understanding its role in high-temperature design

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- What material is used for furnace heating? Select the Right Element for Your Process