At its core, the primary disadvantages of the sintering process are the inherent residual porosity in the final part, significant upfront tooling costs, and limitations on the size and materials that can be effectively processed. These factors mean that while sintering is excellent for mass-producing complex parts, it is often unsuitable for applications requiring maximum material density or for low-volume production runs.

The central challenge of sintering is the trade-off between manufacturing efficiency and material perfection. The process inherently creates parts with a degree of micro-porosity, which can compromise mechanical properties like strength and fatigue life compared to fully dense materials.

The Fundamental Limitation: Residual Porosity

Sintering transforms a loose powder into a solid object, but it rarely achieves the 100% theoretical density of the base material. The small voids left behind are the source of its main drawbacks.

What is Residual Porosity?

Sintering works by heating compacted powder so particles bond together, reducing the space between them. However, it's very difficult to eliminate all these spaces, or pores.

The final product, therefore, contains a network of tiny voids. Advanced variations like Sinter-HIP (Hot Isostatic Pressing) exist specifically to combat this issue by applying high pressure after sintering to further collapse these pores.

Impact on Mechanical Properties

Porosity directly degrades a part's mechanical performance. These microscopic voids act as stress concentrators, which are points where cracks can initiate under load.

This means a sintered part will typically have lower tensile strength, fatigue resistance, and toughness compared to an identical part machined from a solid, forged, or wrought block of the same material.

Implications for Sealing and Permeability

The presence of interconnected pores makes standard sintered parts unsuitable for applications that must be gas-tight or hold pressure.

While this characteristic is a disadvantage for creating sealed containers, it can be intentionally leveraged to produce filters or components designed for gas absorption.

Process and Material Constraints

Beyond porosity, the nature of the sintering process itself imposes several practical and economic limitations.

High Initial Tooling Costs

Sintering requires a precise, durable die to press the initial powder into its "green" shape before heating. The engineering and manufacturing of this tooling are expensive.

This high upfront investment means that sintering is only cost-effective for large production volumes where the tooling cost can be amortized over many thousands or millions of parts.

Limitations on Part Size

Achieving uniform density and temperature throughout a large part during sintering is extremely challenging. Large components are prone to warping, cracking, or having inconsistent properties from the surface to the core.

As a result, sintering is typically reserved for relatively small, intricate components where the process conditions can be tightly controlled.

Material and Geometry Constraints

The process is best suited for materials that can be formed into a powder, primarily metals and ceramics. It is not applicable to many polymers or other material classes.

Furthermore, while sintering excels at complex external shapes, it struggles with certain internal features like undercuts or cross-holes that are impossible to form with a rigid press and die.

Understanding the Trade-offs

Choosing sintering requires a clear understanding of what you are gaining and what you are giving up.

Cost vs. Performance

Sintering offers a cost-effective path to mass-producing parts with complex geometries that would be very expensive to machine. The trade-off is accepting lower mechanical performance due to porosity.

If absolute strength is critical, the cost savings of sintering may be irrelevant, and a more robust manufacturing method is required.

Dimensional Accuracy vs. Shrinkage

Parts shrink as pores are reduced during the heating phase. While this shrinkage is predictable and can be accounted for, it introduces a degree of dimensional variability.

Although sintered parts have high precision, they generally cannot match the ultra-tight tolerances achievable with post-process machining.

Making the Right Choice for Your Application

Sintering is a powerful tool when used correctly. Your decision should be guided by your primary goal.

- If your primary focus is mass production of complex, non-critical parts: Sintering is an ideal choice, as its cost-effectiveness and ability to create near-net shapes outweigh the reduction in material density.

- If your primary focus is maximum strength and fatigue life: Consider alternatives like forging or CNC machining, or specify an advanced process like Sinter-HIP to achieve the required density.

- If your primary focus is low-volume production or prototyping: The high tooling costs of sintering make it uneconomical; methods like machining or additive manufacturing (3D printing) are far better suited.

By understanding these inherent limitations, you can leverage sintering effectively for the right applications and avoid its pitfalls.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Residual Porosity | Lower tensile strength, fatigue resistance, and potential for gas permeability. |

| High Tooling Costs | Significant upfront investment, making it cost-effective only for high-volume production. |

| Size & Geometry Limits | Challenges in producing large parts and complex internal features like undercuts. |

Struggling to decide if sintering is right for your component?

At KINTEK, we specialize in helping you navigate these trade-offs. Our expertise in lab equipment and consumables ensures you select the optimal manufacturing process for your specific needs—whether it's achieving maximum density or cost-effective mass production.

Let our experts guide you to the right solution. Contact KINTEK today for a personalized consultation!

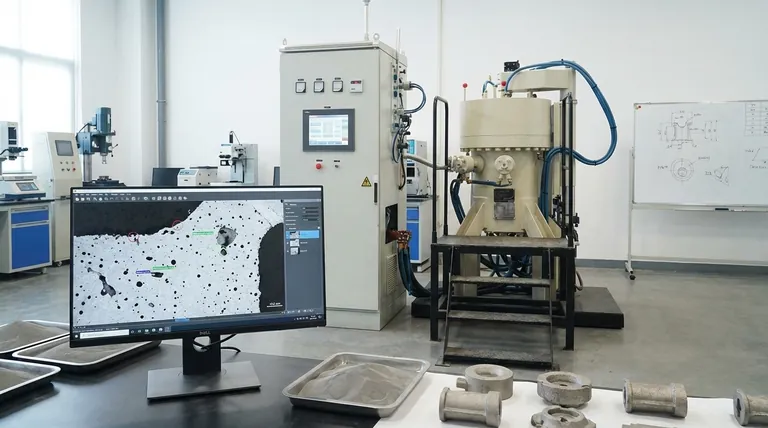

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What critical processing conditions are provided by a vacuum hot press sintering furnace? Achieve 98%+ Density.

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al

- What conditions does a vacuum hot press provide for Al2O3/ZrO2 sintering? Achieve 1550°C and 30 MPa Densification