While a foundational and widely used technique, thermal evaporation is not without significant drawbacks. Its primary disadvantages are high levels of film impurity, the creation of low-density films, and a limited range of compatible materials, making it unsuitable for applications requiring high-purity, dense coatings or the deposition of refractory metals.

Thermal evaporation's core trade-off is its simplicity and high deposition rate in exchange for less control over film purity and structural quality. This makes it ideal for some applications but a non-starter for others where material integrity is paramount.

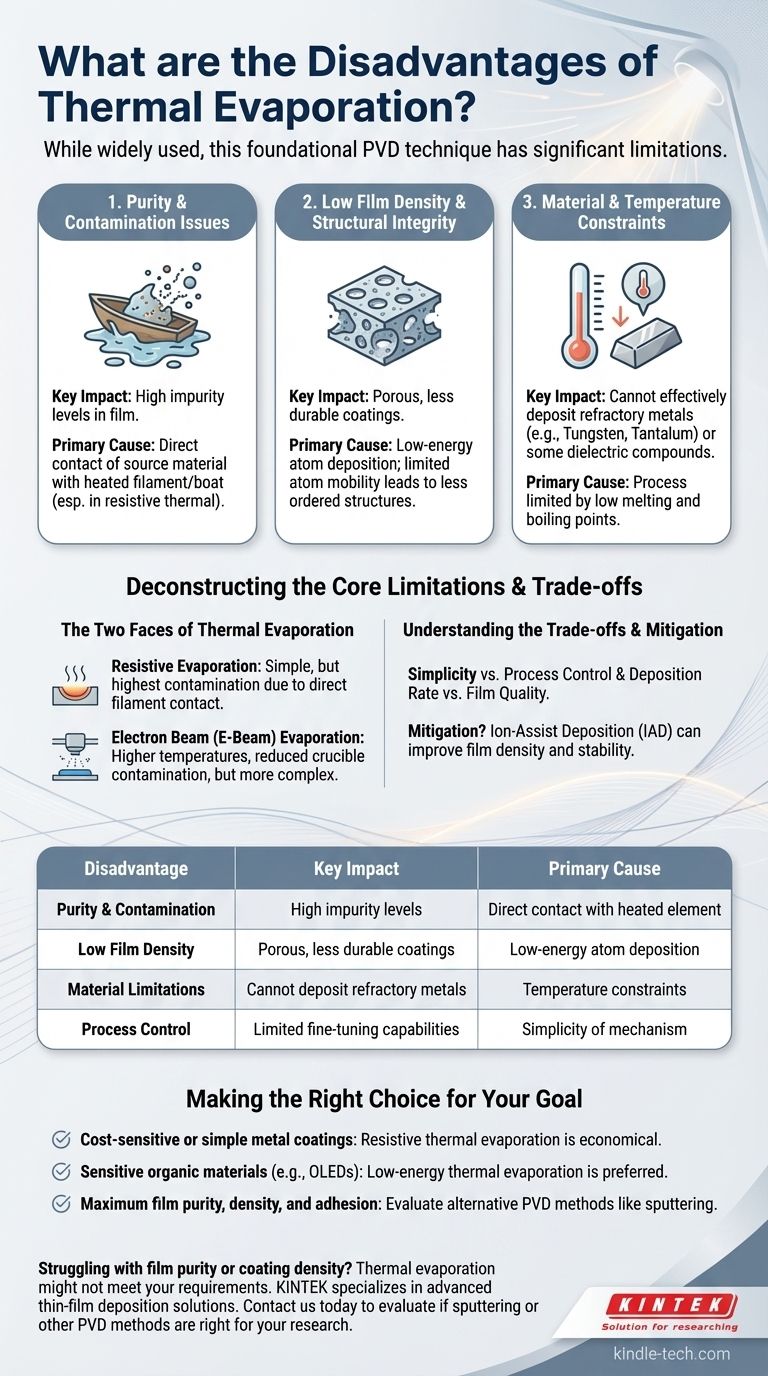

Deconstructing the Core Limitations

To understand if thermal evaporation is right for your project, you must first understand the "why" behind its disadvantages. These issues are not flaws in the process but inherent consequences of its fundamental mechanism.

Purity and Contamination Issues

The most significant disadvantage is the potential for contamination. In resistive thermal evaporation, the source material is in direct contact with a heated filament or "boat," often made of tungsten or molybdenum.

At high temperatures, the boat material itself can evaporate slightly, incorporating impurities directly into your thin film. This makes thermal evaporation one of the least pure methods among Physical Vapor Deposition (PVD) techniques.

Film Density and Structural Integrity

Atoms leave the source material with relatively low thermal energy. When they arrive at the substrate, they have limited mobility to arrange themselves into a dense, ordered crystal structure.

This results in films that are often porous and have a lower density compared to those created by higher-energy processes like sputtering. While this can sometimes be improved with techniques like ion-assist, the baseline quality is inherently lower. The films can also exhibit moderate internal stress.

Material and Temperature Constraints

The process relies on heating a material until its vapor pressure is high enough for deposition. This fundamentally limits its use to materials with relatively low melting and boiling points.

Refractory metals like tungsten, tantalum, or molybdenum, which require extremely high temperatures to vaporize, are very difficult or impossible to deposit effectively using standard thermal evaporation. Dielectric compounds can also be challenging to evaporate stoichiometrically.

The Two Faces of Thermal Evaporation

It is critical to distinguish between the two main types of thermal evaporation, as their capabilities and disadvantages differ.

Resistive (Filament) Evaporation: The Simplest Form

This is the classic, most straightforward method where current is passed through a resistive filament holding the source material.

Its main disadvantage is the direct contact between the source and the hot filament, which is the primary source of contamination. It is also the most temperature-limited of the two methods.

Electron Beam (E-Beam) Evaporation: A Step Up

In this method, a high-energy electron beam is magnetically guided to heat the source material directly in a crucible. This allows for much higher temperatures, enabling the deposition of a wider range of materials.

Because only the top surface of the material is heated, contamination from the crucible is significantly reduced, though not eliminated. However, E-beam systems are more complex and expensive than simple resistive sources.

Understanding the Trade-offs

Choosing a deposition method is always about balancing competing factors. Thermal evaporation's disadvantages become clear when viewed as trade-offs.

Simplicity vs. Process Control

Thermal evaporation is mechanically simple and relatively inexpensive to implement. This is its greatest strength. However, this simplicity comes at the cost of the fine process control offered by more complex systems like magnetron sputtering.

Deposition Rate vs. Film Quality

The technique is capable of very high deposition rates, which is a major advantage for industrial-scale production, such as metallizing decorative parts or producing OLEDs.

This speed, however, is directly linked to the lower-energy deposition that results in less dense films. For applications where speed is more critical than ultimate film performance, this is an acceptable trade-off.

Can These Disadvantages Be Mitigated?

Yes, to an extent. Using ion-assist deposition (IAD) can bombard the growing film with energetic ions, compacting it and improving its density and stability. Furthermore, careful processing of source materials, such as pre-melting or using high-purity starting slugs, can help reduce some contamination.

Making the Right Choice for Your Goal

Your application's specific requirements will determine whether the disadvantages of thermal evaporation are acceptable.

- If your primary focus is cost-sensitive applications or simple metal coatings: Resistive thermal evaporation is often sufficient and highly economical for decorative coatings or basic electrical contacts.

- If your primary focus is depositing sensitive organic materials: Low-energy thermal evaporation is a leading choice for manufacturing OLEDs, as higher-energy processes can damage the delicate molecules.

- If your primary focus is maximum film purity, density, and adhesion: You should evaluate alternative PVD methods like sputtering, as the inherent limitations of thermal evaporation will likely be a significant barrier.

Understanding these fundamental trade-offs allows you to select the right deposition technique for your specific material and performance goals.

Summary Table:

| Disadvantage | Key Impact | Primary Cause |

|---|---|---|

| Purity & Contamination | High impurity levels in film | Direct contact with heated filament/boat |

| Low Film Density | Porous, less durable coatings | Low-energy atom deposition |

| Material Limitations | Cannot deposit refractory metals | Temperature constraints of evaporation process |

| Process Control | Limited fine-tuning capabilities | Simplicity of the evaporation mechanism |

Struggling with film purity or coating density in your lab? Thermal evaporation might not be meeting your material performance requirements. At KINTEK, we specialize in lab equipment and consumables for advanced thin-film deposition. Our experts can help you evaluate if sputtering or other PVD methods would deliver the high-purity, dense coatings your research demands. Contact us today to discuss your specific application and find the right solution for your laboratory's thin-film needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the current of e-beam evaporation? A Guide to High-Purity Thin Film Deposition

- What is the vacuum evaporation mechanism? A Guide to High-Purity Thin Film Deposition

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- How does electron beam curing work? Achieve Instant, Durable Curing for Industrial Applications

- How is physical vapor deposition performed using an electron beam evaporator? A Guide to High-Purity Thin Films

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is the difference between thermal and electron beam evaporation? Unlock the Right Thin Film Deposition Method

- What are the applications of evaporation in industries? From Wastewater to Electronics