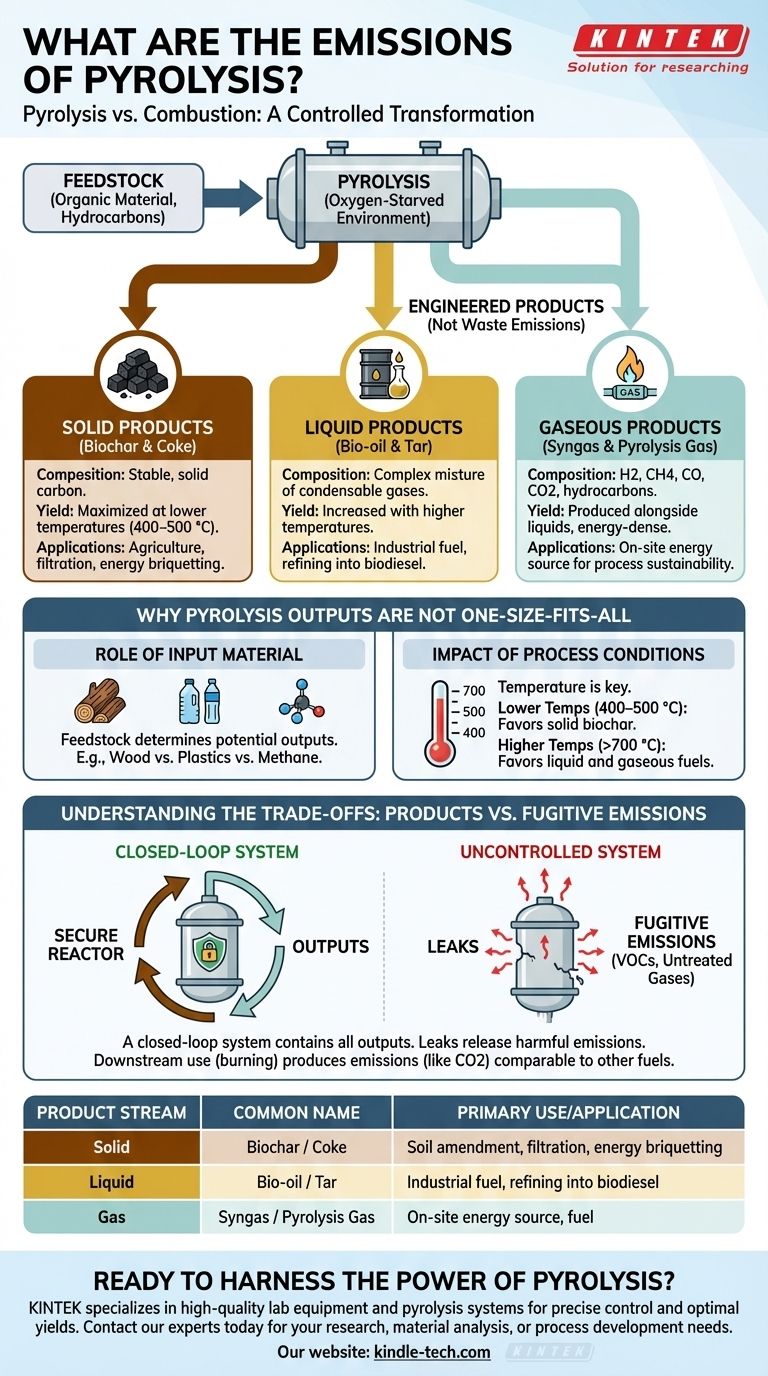

To be precise, pyrolysis is a process of thermal decomposition, not combustion. Therefore, it does not produce "emissions" in the way a smokestack does. Instead, it transforms a single input material into three distinct categories of valuable products: a solid, a liquid, and a gas. The exact composition of these outputs is entirely dependent on the initial material and the specific process conditions used.

The core misunderstanding is thinking of pyrolysis outputs as waste emissions. In a properly controlled system, the outputs are engineered products—solids (like biochar), liquids (like bio-oil), and gases (like syngas)—each with specific industrial or energy applications.

The Three States of Pyrolysis Products

Pyrolysis deconstructs organic material or hydrocarbons in an oxygen-starved environment. This prevents burning and instead breaks the material down into its constituent parts, which are then captured as distinct product streams.

Solid Products (Biochar & Coke)

The primary solid output is a carbon-rich material known as biochar (from biomass) or coke.

This solid is what remains after most volatile components have been vaporized. Its primary component is stable, solid carbon.

Lower pyrolysis temperatures, typically around 400–500 °C, are specifically used to maximize the yield of this solid product for applications in agriculture, filtration, or energy briquetting.

Liquid Products (Bio-oil & Tar)

As the process temperature increases, a complex mixture of condensable gases is formed. When this vapor is cooled, it becomes a liquid product.

This liquid is often called pyrolysis oil (or bio-oil), but can also include fractions like wood vinegar or tar depending on the feedstock.

This oil can be used as an alternative industrial fuel or be further refined into higher-grade products like biodiesel.

Gaseous Products (Pyrolysis Gas)

The non-condensable gases that remain after the liquid has been separated form the third product stream, often called pyrolysis gas or syngas.

This gas is a mixture that can include hydrogen (H2), methane (CH4), carbon monoxide (CO), carbon dioxide (CO2), and various other hydrocarbons.

Crucially, this gas has significant energy value. In most modern pyrolysis plants, this gas is captured and used to provide the heat needed to sustain the pyrolysis reaction, making the system highly energy-efficient.

Why Pyrolysis Outputs Are Not One-Size-Fits-All

The specific ratio and chemical makeup of the solid, liquid, and gas products are not fixed. They are deliberately manipulated by controlling two key variables.

The Role of Input Material (Feedstock)

The starting material fundamentally dictates the potential outputs. The products from pyrolyzing wood are drastically different from those of other materials.

For example, the pyrolysis of waste plastics yields different oils and waxes. The pyrolysis of methane is a specialized process designed to produce two clean products: solid carbon and gaseous hydrogen.

The Impact of Process Conditions

Temperature is the most critical control lever. As a general principle, operators can steer the output ratio based on their goals.

Lower temperatures (400–500 °C) favor the production of solid biochar.

Higher temperatures (above 700 °C) "crack" the material more completely, favoring higher yields of liquid and gaseous fuels.

Understanding the Trade-offs: Products vs. Fugitive Emissions

While a controlled pyrolysis system converts inputs to products, the primary environmental concern is the potential for uncontrolled or fugitive emissions.

A Closed-Loop System is Essential

The objective of a well-engineered pyrolysis facility is to be a closed-loop system. All three output streams—solid, liquid, and gas—are contained and directed for collection or use.

Any leaks in the system could release volatile organic compounds (VOCs) or other untreated gases, which would be considered harmful emissions. The integrity of the equipment is therefore paramount.

Downstream Emissions Still Matter

It is important to remember that the pyrolysis products themselves have an emissions profile when they are used.

Burning the bio-oil or syngas for energy will produce emissions, such as CO2, comparable to other fuels. The environmental benefit is rooted in the feedstock, such as converting a waste product into a useful fuel.

Making the Right Choice for Your Goal

The "emissions" of pyrolysis are best understood as engineered outputs. The process should be chosen based on the desired end product.

- If your primary focus is carbon sequestration or soil amendment: You should utilize lower-temperature pyrolysis of biomass to maximize the output of stable, solid biochar.

- If your primary focus is energy production from waste: You should utilize higher-temperature pyrolysis to maximize the yield of energy-dense bio-oil and combustible syngas.

- If your primary focus is producing clean hydrogen: You should look to specialized methane pyrolysis, which is designed specifically to split natural gas into solid carbon and hydrogen gas.

Ultimately, understanding the outputs of pyrolysis is about controlling a powerful transformation process to create value rather than waste.

Summary Table:

| Product Stream | Common Name | Primary Use/Application |

|---|---|---|

| Solid | Biochar (from biomass) / Coke | Soil amendment, filtration, energy briquetting |

| Liquid | Bio-oil / Tar | Industrial fuel, refining into biodiesel |

| Gas | Syngas / Pyrolysis Gas | On-site energy source for the process, fuel |

Ready to harness the power of pyrolysis for your lab or project? KINTEK specializes in high-quality lab equipment and consumables, including pyrolysis systems designed for precise control and optimal product yields. Whether your goal is research, material analysis, or process development, our solutions help you convert materials into valuable products efficiently and safely. Contact our experts today to discuss how we can support your specific laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Variable Speed Peristaltic Pump

People Also Ask

- What is the chemical reaction of pyrolysis? A Guide to Controlled Thermal Decomposition

- What is the process of biomass pyrolysis? Converting Biomass into Bio-char, Bio-oil, and Syngas

- What fuel is used in rotary kilns? Optimize Your Kiln's Efficiency and Cost

- What are the characteristics of the slipping, slumping, and rolling modes of bed motion? Optimize Your Rotary Process

- What is pyrolysis rate? Mastering Control for Optimal Bio-Char, Bio-Oil, and Syngas Production

- How does a rotary kiln operate? Master Continuous High-Temperature Processing

- How many degrees is the rotary kiln heated? Unlock the Key to Your Process Temperature

- What is the importance of a high-temperature electric firing kiln in the final preparation of dense refractory bricks?