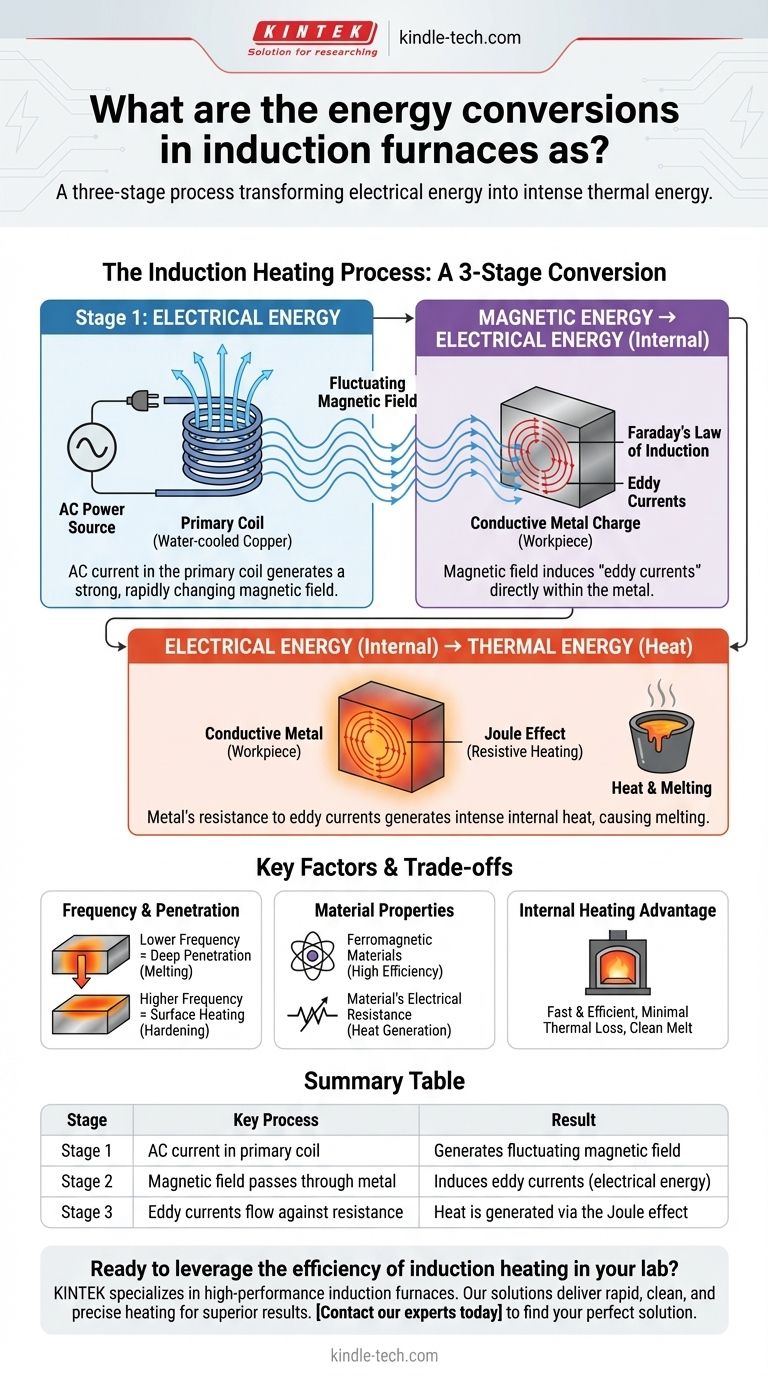

At its core, an induction furnace executes a three-stage energy conversion process. It transforms initial electrical energy into a powerful, fluctuating magnetic field. This magnetic field then induces a secondary electrical current directly within the conductive metal, which is finally converted into intense thermal energy due to the metal's inherent resistance.

An induction furnace functions like a transformer where the metal being heated is the short-circuited secondary coil. The process hinges on two physical laws: electromagnetic induction to create current in the metal, and the Joule effect to convert that current directly into heat.

The First Stage: From Electrical to Magnetic Energy

The entire process begins with a powerful alternating current (AC) source. This is the primary energy input for the system.

The Primary Coil

An induction furnace is built around a water-cooled copper coil. This coil acts as the primary inductor in the system.

Generating a Magnetic Field

When AC electricity flows through this primary coil, it generates a strong, rapidly changing magnetic field around and within the coil. This completes the first conversion: electrical energy to magnetic energy.

The Second Stage: From Magnetic back to Electrical Energy

This is where the principle of non-contact heating becomes critical. The magnetic field created by the coil is the medium that transfers energy to the metal charge.

Faraday's Law of Induction

The fluctuating magnetic field passes through the conductive metal placed inside the furnace. According to Faraday's Law of Induction, this changing magnetic field induces an electrical current within the metal itself.

The Formation of Eddy Currents

These induced currents are known as eddy currents. They flow in closed loops within the metal, mirroring the current in the primary coil but without any physical connection. This completes the second conversion: magnetic energy back to electrical energy, but now located inside the workpiece.

The Final Conversion: The Joule Effect

The generation of eddy currents is not the end goal; it is the mechanism used to generate the final, desired form of energy.

The Role of Electrical Resistance

Every conductive material has some level of electrical resistance. This property impedes the free flow of electrons.

From Current to Heat

As the powerful eddy currents flow through the metal's resistance, the energy of the moving electrons is converted directly into heat. This phenomenon is known as the Joule effect or resistive heating. This is the final and most important conversion: electrical energy to thermal energy, causing the metal to heat up and eventually melt.

Understanding the Trade-offs and Key Factors

The efficiency and application of an induction furnace are directly tied to the physics of these energy conversions. Understanding these factors is key to its proper use.

Frequency and Penetration Depth

The frequency of the initial AC current is a critical control parameter. Lower frequencies create magnetic fields that penetrate deeper, generating heat throughout a large volume of metal, which is ideal for melting. Higher frequencies cause the eddy currents to form only near the surface, a phenomenon known as the "skin effect," which is ideal for precise surface hardening.

Material Properties Matter

The process is most efficient for ferromagnetic materials (like iron) below their Curie temperature, as they interact strongly with the magnetic field. The material's specific electrical resistance also dictates how effectively the eddy currents are converted into heat.

The Advantage of Internal Heating

Because heat is generated inside the workpiece, the process is incredibly fast and efficient. There is minimal thermal loss to the surrounding environment compared to a furnace that relies on external combustion or radiation to transfer heat. This also ensures a very clean melt with few impurities.

Making the Right Choice for Your Goal

Understanding this energy conversion sequence allows you to see why induction technology is chosen for specific industrial tasks.

- If your primary focus is rapid, clean melting: The direct internal heat generation from the Joule effect is why this method is faster and cleaner than fuel-fired furnaces.

- If your primary focus is precise surface hardening: The ability to control heat penetration by adjusting the AC frequency is a direct consequence of the electromagnetic principles at play.

- If your primary focus is energy efficiency: The furnace's "transformer" nature ensures energy is transferred directly to the workpiece, minimizing the waste heat common in other methods.

Mastering this technology begins with a clear understanding of the elegant physics converting electricity into heat without contact.

Summary Table:

| Energy Conversion Stage | Key Process | Result |

|---|---|---|

| Stage 1 | AC current in the primary coil | Generates a fluctuating magnetic field |

| Stage 2 | Magnetic field passes through metal | Induces eddy currents (electrical energy) |

| Stage 3 | Eddy currents flow against resistance | Heat is generated via the Joule effect |

Ready to leverage the efficiency of induction heating in your lab?

KINTEK specializes in high-performance lab equipment, including induction furnaces. Our solutions deliver the rapid, clean, and precise heating your processes demand, directly translating to improved efficiency and superior results.

Contact our experts today to find the perfect induction heating solution for your specific application!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting