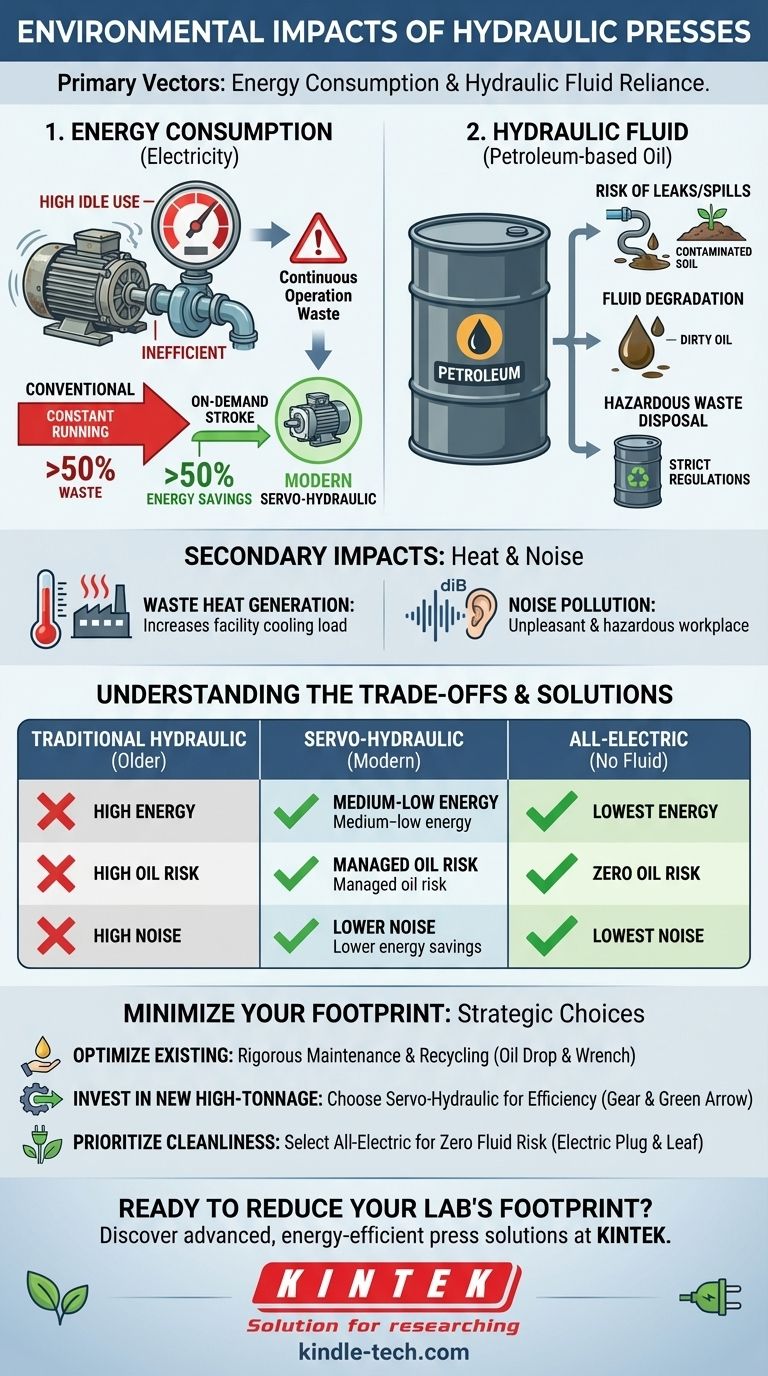

In short, the primary environmental impacts of a hydraulic press are not from its physical operation but from its supporting systems: its significant energy consumption and its reliance on petroleum-based hydraulic fluid. While powerful and versatile, a traditional hydraulic press carries a notable environmental footprint related to electricity usage, the risk of oil leaks, and the disposal of used fluid as hazardous waste.

The environmental performance of a hydraulic press is a direct reflection of its design and maintenance. While older, continuously running models are inefficient, modern servo-hydraulic and all-electric alternatives offer a clear path toward minimizing energy use and eliminating oil-related hazards.

The Two Primary Impact Vectors: Energy and Fluid

The environmental discussion around hydraulic presses centers on two critical resources they consume: electricity and oil. Understanding how these are used is the key to assessing and mitigating their impact.

Analyzing Energy Consumption

A hydraulic press requires an electric motor to run a pump, which pressurizes the hydraulic fluid to generate force. This system's efficiency is a major environmental factor.

A significant issue, especially in older designs, is idle energy consumption. The motor and pump often run continuously to maintain system pressure, even when the press is not actively forming a part. This standby mode can account for a substantial portion of the machine's total energy use, representing pure waste.

Modern designs, such as servo-hydraulic presses, directly address this by using motors that only operate on-demand during the press stroke. This drastically reduces idle consumption and can cut total energy use by over 50% compared to conventional models.

The Lifecycle of Hydraulic Fluid

Most hydraulic presses use thousands of gallons of petroleum-based oil over their lifespan, creating several environmental risk points.

The most immediate risk is leaks and spills. Worn seals, burst hoses, or loose fittings are common maintenance issues that can release oil into the environment, contaminating soil and groundwater. Containing and cleaning these spills is a critical operational responsibility.

Furthermore, hydraulic fluid degrades over time and requires periodic replacement. Used hydraulic oil is classified as hazardous waste in many regions. It cannot be thrown away; it must be collected, transported, and recycled or disposed of according to strict environmental regulations.

Secondary Environmental Considerations

Beyond the main issues of energy and fluid, other factors contribute to the overall environmental profile of a hydraulic press.

Heat Generation as Waste

Inefficiencies in the hydraulic system—especially in older, constant-running pumps—generate a significant amount of waste heat. This heat is radiated into the facility, increasing the ambient temperature and placing a greater load on the building's cooling and HVAC systems, which in turn consumes more energy.

Noise Pollution

The hydraulic power unit (HPU) is a primary source of noise in a manufacturing environment. Constant noise levels often exceeding 85 dBA can create an unpleasant and hazardous workplace, representing a form of localized environmental pollution that impacts employee health and well-being.

Understanding the Trade-offs: Hydraulic vs. Alternatives

Choosing a press technology involves balancing performance, cost, and environmental impact. The hydraulic press, while having clear environmental drawbacks, has historically been favored for its force capacity and flexibility.

The Rise of All-Electric Presses

For applications requiring maximum cleanliness and energy efficiency, all-electric (or servo) presses are the superior choice. They use servo motors to directly drive the press ram, eliminating the need for any hydraulic fluid. This completely removes the risks of leaks, spills, and fluid disposal.

Their energy consumption is also the lowest in the industry, as they only draw significant power during the actual work stroke. The primary trade-offs are typically a higher initial purchase price and, in some cases, limitations on maximum tonnage compared to the largest hydraulic systems.

Legacy and Modern Hydraulic Systems

It is crucial to distinguish between a 20-year-old conventional hydraulic press and a modern servo-hydraulic model. While both use oil, the latter's energy efficiency is much closer to that of an all-electric press. For very high-tonnage applications, a servo-hydraulic press often represents the best balance of force, control, and reduced environmental impact.

Minimizing Your Environmental Footprint

Your strategy for mitigating the environmental impact of a press depends on your specific goals and equipment.

- If your primary focus is operating existing hydraulic presses responsibly: Prioritize a rigorous maintenance schedule to fix leaks immediately, and establish a compliant process for capturing and recycling used oil.

- If your primary focus is investing in a new high-tonnage press: Choose a modern servo-hydraulic system to gain massive energy savings over conventional designs while still achieving your required force.

- If your primary focus is maximum energy efficiency and environmental cleanliness: An all-electric press is the definitive choice, as it eliminates hydraulic fluid entirely and offers the lowest possible energy consumption.

By understanding these core factors, you can make an informed decision that aligns your production requirements with responsible environmental stewardship.

Summary Table:

| Impact Category | Primary Source | Key Consideration |

|---|---|---|

| Energy Consumption | Electric motor and pump system | High idle consumption in older models; modern servo-hydraulic cuts energy use by >50%. |

| Hydraulic Fluid | Petroleum-based oil | Risk of leaks/spills; used oil is hazardous waste requiring special disposal. |

| Secondary Impacts | Heat generation and noise | Waste heat increases cooling load; noise pollution affects workplace safety. |

| Cleaner Alternatives | All-electric or servo-hydraulic presses | Eliminate fluid risks and offer superior energy efficiency for many applications. |

Ready to reduce your lab's environmental footprint?

Choosing the right press technology is crucial for balancing performance with sustainability. At KINTEK, we specialize in lab equipment and consumables, offering advanced solutions like energy-efficient servo-hydraulic and all-electric presses tailored to your laboratory needs.

Let our experts help you select a press that minimizes energy use, eliminates fluid hazards, and aligns with your environmental goals.

Contact us today for a personalized consultation and discover how KINTEK can enhance your lab's efficiency and sustainability!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples