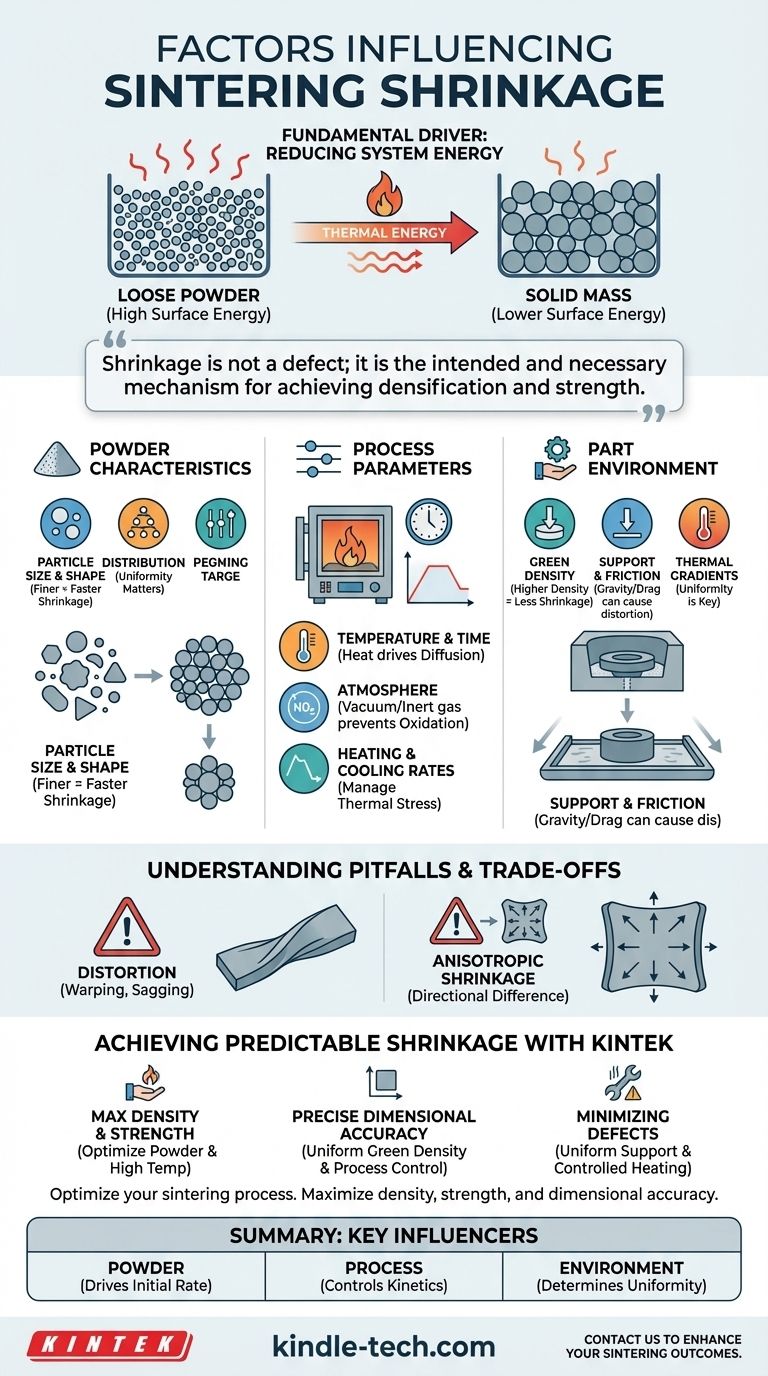

At its core, shrinkage during sintering is governed by three primary categories of factors: the intrinsic characteristics of the powder material, the specific process parameters you control, and the physical environment of the part. This process is driven by a fundamental need to reduce the system's surface energy, which manifests as the consolidation of loose powder into a dense, solid object.

Shrinkage is not a defect in sintering; it is the intended and necessary mechanism for achieving densification and strength. The goal is not to eliminate shrinkage but to understand and precisely control it to produce a part with the desired final dimensions and properties.

The Fundamental Driver: Reducing System Energy

Before you can control shrinkage, you must understand why it happens. The entire process is a result of thermodynamics, where the material seeks its lowest possible energy state.

From Loose Powder to a Solid Mass

A volume of loose powder has an immense amount of surface area compared to a solid block of the same material. This vast surface area corresponds to a high state of surface energy. Sintering provides the thermal energy needed for atoms to move and rearrange themselves to minimize this energy.

Surface Tension as the Driving Force

At high temperatures, well below the material's melting point, atoms gain enough mobility to diffuse. Surface tension, the same force that pulls water droplets into a sphere, acts on the surfaces of the powder particles. It pulls atoms from the particles' surfaces into the "necks" forming between them, causing the particles to merge and the pores (empty spaces) to shrink.

The Mechanism of Mass Transport

This reduction in volume occurs through several stages. Initially, particles repack into a denser arrangement. Then, material transport begins, primarily through diffusion, where atoms move along grain boundaries to fill the internal pores. As these pores close, the overall volume of the part decreases, resulting in shrinkage.

Key Factors You Can Control

Managing shrinkage requires manipulating the variables that influence the rate and extent of atomic diffusion and material consolidation.

Powder Characteristics

The starting material is your first and most critical lever. The size, shape, and distribution of the powder particles dictate how they pack together and the initial amount of pore space. Finer powders have higher surface energy and sinter more readily, typically resulting in greater and more rapid shrinkage.

Compaction and Green Density

Green density refers to the density of the part after it has been compacted but before sintering. A part with higher green density has less internal pore volume to begin with. Consequently, it will experience less shrinkage to reach its final density. Uniform compaction is critical for predictable, consistent shrinkage.

Sintering Temperature and Time

Temperature is the most powerful parameter. Higher temperatures provide more thermal energy, dramatically increasing the rate of atomic diffusion and accelerating densification and shrinkage. The duration at peak temperature also determines how completely the process runs to its conclusion.

Sintering Atmosphere

The atmosphere inside the furnace—whether it's a vacuum, an inert gas like argon, or a reducing atmosphere—is crucial. It prevents oxidation, which can inhibit diffusion and stop the sintering process. The atmosphere can also influence surface chemistry, directly affecting how easily atoms can move.

Heating and Cooling Rates

The speed at which you heat and cool the part matters. Rapid heating can create significant temperature differences between the surface and the core of a part, causing thermal stress and cracking. The cooling rate influences the final microstructure and can also introduce stress if not managed carefully.

Understanding the Pitfalls and Trade-offs

Ideal shrinkage is uniform and predictable. In reality, several forces work against this, leading to common manufacturing defects.

Shrinkage vs. Distortion

While shrinkage is desired, non-uniform shrinkage results in distortion. This includes warping, twisting, or a general failure to meet dimensional tolerances. The primary challenge in sintering is achieving the target shrinkage without introducing unacceptable distortion.

The Influence of Gravity and Friction

During sintering, the part becomes soft and susceptible to external forces. Gravity can cause unsupported sections or long spans to sag. Similarly, friction between the part and the surface it rests on can constrain shrinkage in one area while allowing it in others, generating internal stress that can lead to warping or cracking.

Anisotropic Shrinkage

Anisotropic shrinkage occurs when the part shrinks by different amounts in different directions. This is often caused by non-uniform density during the initial powder compaction stage. If particles are preferentially aligned during pressing, shrinkage will be greater perpendicular to the direction of pressing.

Achieving Predictable Shrinkage for Your Goal

Controlling shrinkage requires a holistic approach, balancing material science with process engineering. Your strategy will depend on your primary objective.

- If your primary focus is maximum density and strength: Use fine, uniform powders and optimize compaction for high green density, then sinter at the upper end of the material's recommended temperature range.

- If your primary focus is precise dimensional accuracy: Begin with extremely uniform green density, use process modeling to predict shrinkage, and implement precise control over the entire thermal cycle and part support structure.

- If your primary focus is minimizing defects like warping: Ensure uniform part support, use controlled heating and cooling rates to manage thermal gradients, and design the part to avoid long, unsupported features.

Mastering the sintering process is a matter of deliberately controlling these variables to make shrinkage work for you, not against you.

Summary Table:

| Factor Category | Key Variables | Primary Influence on Shrinkage |

|---|---|---|

| Powder Characteristics | Particle size, shape, distribution | Drives the initial rate and extent of densification |

| Process Parameters | Sintering temperature, time, atmosphere | Controls the kinetics of atomic diffusion and pore removal |

| Part Environment | Green density, support, thermal gradients | Determines uniformity and potential for distortion |

Achieve precise dimensional control in your sintering process. Unpredictable shrinkage can lead to costly defects and inconsistent part quality. At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your sintering needs. Our expertise helps you optimize powder characteristics, fine-tune process parameters, and manage part environments to ensure uniform, predictable shrinkage—maximizing density, strength, and dimensional accuracy. Contact us today to discuss how our solutions can enhance your sintering outcomes and deliver reliable performance for your laboratory. Reach out now via our contact form to get started!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does an alumina tube furnace with a controlled atmosphere simulate conditions in CSP environments? Master Accuracy.

- How do I choose a tube furnace? A Guide to Matching Your Process Needs

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System