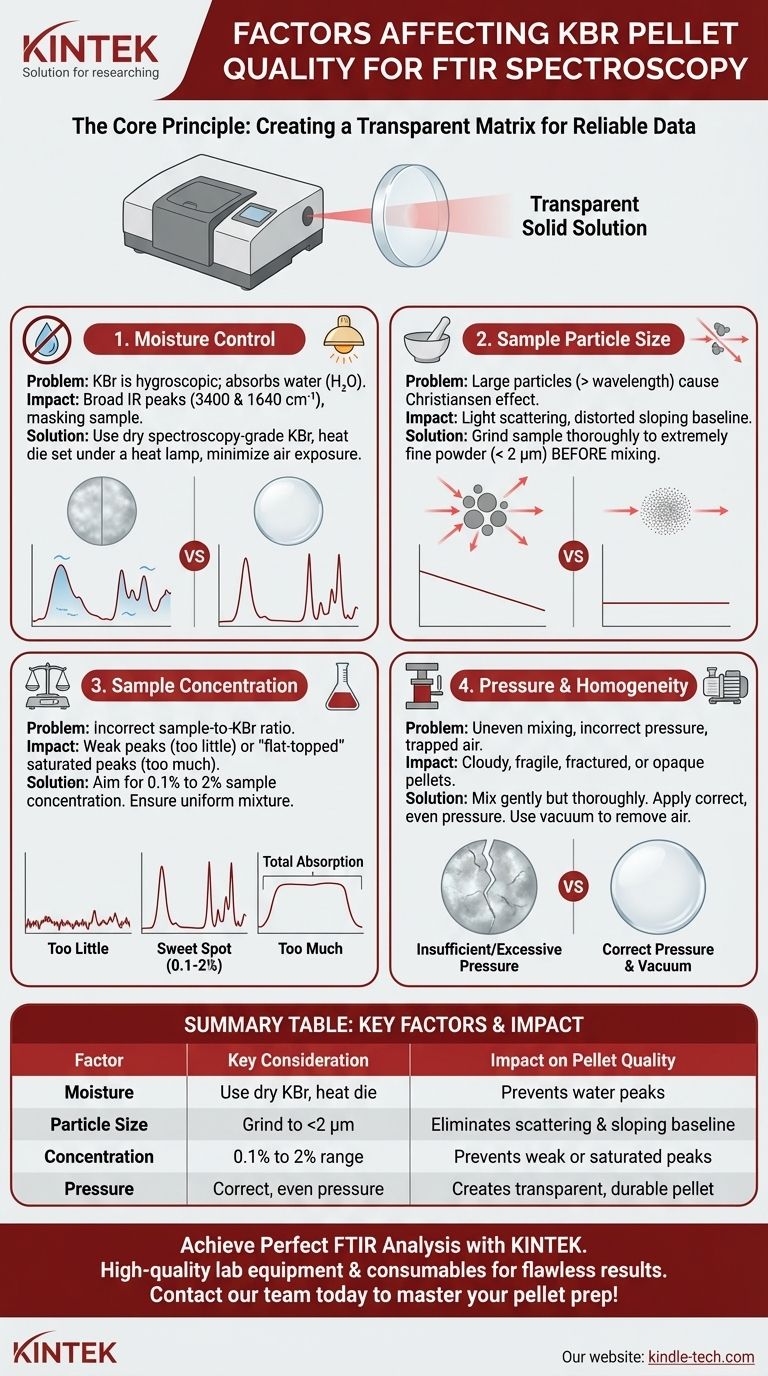

At its core, creating a high-quality KBr pellet for FTIR spectroscopy depends on four critical factors: moisture control, sample particle size, sample concentration, and the application of correct, even pressure. Success is determined by how well you can create a transparent solid solution, and failure in any of these areas will introduce artifacts like scattering or unwanted peaks into your spectrum, obscuring your results.

The ultimate goal is to create a perfectly transparent, solid "window" where your sample is evenly dispersed in an infrared-invisible matrix. The primary obstacles to achieving this clarity are moisture, which adds its own strong IR signal, and particles that are too large, which scatter the instrument's light beam.

The Core Principle: Creating a Transparent Matrix

The KBr pellet method works because potassium bromide (KBr) is transparent to infrared radiation in the mid-IR range (4000-400 cm⁻¹) where most functional groups absorb.

The pellet acts as a solid-state solvent. Your finely ground sample is dispersed within this KBr matrix. For the analysis to be accurate, the pellet must be perfectly transparent and homogenous, allowing the instrument's IR beam to pass through without interference.

Controlling the Critical Factors

Any deviation from an ideal, transparent pellet will degrade the quality of your final spectrum. Mastering the following variables is essential for producing reliable data.

Moisture: The Primary Enemy

KBr is highly hygroscopic, meaning it readily absorbs moisture from the atmosphere. Water (H₂O) has very strong, broad absorption bands in the infrared spectrum (around 3400 cm⁻¹ and 1640 cm⁻¹) that can easily mask the peaks from your actual sample.

To combat this, you must be meticulous. Heat your die set and anvils under a heat lamp before use to drive off any surface moisture. Use only dry, spectroscopy-grade KBr powder, and work quickly to minimize its exposure to air.

Particle Size: The Key to Clarity

If the particle size of your sample is larger than or similar to the wavelength of the IR light, it will cause light scattering. This phenomenon, known as the Christiansen effect, results in a distorted, sloping baseline that can make it impossible to identify small peaks or perform quantitative analysis.

The rule is simple: the sample must be ground into an extremely fine powder, ideally to a particle size of less than 2 micrometers. This is why you must thoroughly grind the sample (often with an agate mortar and pestle) before mixing it with the KBr.

Sample Concentration: Finding the Sweet Spot

The amount of your sample relative to the KBr is critical. The goal is typically a concentration of 0.1% to 2% sample in KBr.

Too little sample will result in weak, noisy peaks that are difficult to distinguish from the baseline. Too much sample causes peaks to become overly intense and "flat-topped," a phenomenon called total absorption. These saturated peaks are not analytically useful.

Homogeneity: Ensuring a Uniform Mixture

Your finely ground sample must be evenly distributed throughout the KBr powder. If the sample is clumped together, the IR beam may pass through a section with too little sample or too much, leading to a non-representative and distorted spectrum.

After grinding the sample, mix it gently but thoroughly with the KBr powder. Avoid aggressive grinding during this mixing step, as this needlessly increases the surface area of the KBr and accelerates moisture absorption.

Understanding the Trade-offs and Equipment

The physical act of pressing the pellet introduces its own set of variables that require careful management.

Insufficient vs. Excessive Pressure

Applying pressure fuses the KBr powder into a transparent or translucent disc. Insufficient pressure will result in a cloudy, fragile pellet that scatters light significantly.

Conversely, excessive pressure can cause the pellet to fracture or become opaque. High pressure can sometimes induce changes in the crystal lattice of the KBr, which can also interfere with the spectrum.

The Role of Vacuum

Many die sets are designed to be used under vacuum. Pulling a vacuum during the pressing process helps remove trapped air and residual moisture from the powder mixture.

This removal of trapped gases is crucial for creating a highly transparent, glass-like pellet. If using a vacuum die, ensure all seals are clean and functioning properly to achieve an effective vacuum.

The "Don't Grind KBr" Rule Explained

You should grind the sample, but never grind the KBr powder by itself. High-purity, FTIR-grade KBr is already manufactured to a suitable particle size. Grinding it further dramatically increases its surface area, causing it to absorb atmospheric moisture at an accelerated rate, which defeats the primary goal of keeping the system dry.

Making the Right Choice for Your Goal

Use these guidelines to troubleshoot your process and achieve consistent, high-quality results.

- If your primary focus is eliminating a sloping baseline: Your main problem is light scattering, so you must grind your sample more thoroughly to a smaller particle size.

- If your primary focus is removing broad water peaks: You have a moisture problem. Ensure your KBr is dry, your die set is heated, and you minimize air exposure time.

- If your primary focus is getting quantifiable peak intensities: Your sample concentration is off. Aim for the 0.1-2% range and ensure your peaks are sharp, not flat-topped.

- If your primary focus is preventing cloudy or cracked pellets: Re-evaluate your pressing technique. Ensure you are applying sufficient (but not excessive) pressure and are using a vacuum if your die allows it.

Mastering these fundamental factors will transform your pellet preparation from a source of frustration into a reliable and precise analytical technique.

Summary Table:

| Factor | Key Consideration | Impact on Pellet Quality |

|---|---|---|

| Moisture Control | Use dry KBr, heat die set | Prevents broad water peaks in spectrum |

| Particle Size | Grind sample to <2 μm | Eliminates light scattering & sloping baseline |

| Sample Concentration | 0.1% to 2% sample in KBr | Prevents weak or saturated peaks |

| Pressure Application | Apply correct, even pressure | Creates a transparent, durable pellet |

Achieve Perfect FTIR Analysis with KINTEK

Struggling with cloudy pellets or distorted spectra? The quality of your KBr pellet is the foundation of reliable FTIR data. KINTEK specializes in high-quality lab equipment and consumables, including reliable pellet dies and spectroscopy-grade KBr, designed to help you master moisture control, particle size, and pressing technique.

Let our expertise support your research. Contact our team today to find the right solutions for your laboratory's specific pellet preparation needs and ensure flawless results every time.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy