Beyond the obvious chemical dangers, the primary hazards of chemical vapor deposition (CVD) are rooted in its demanding process conditions and significant operational limitations. These include the use of highly toxic or pyrophoric precursor gases, the risk of material damage from extreme heat, and fundamental challenges in controlling the quality of multi-component or bulk materials.

While CVD offers unmatched precision for thin film deposition, its true risks lie beyond the lab. The process is operationally demanding, limited by equipment size and high temperatures, and can present significant quality control challenges, making it a specialized tool rather than a universal solution.

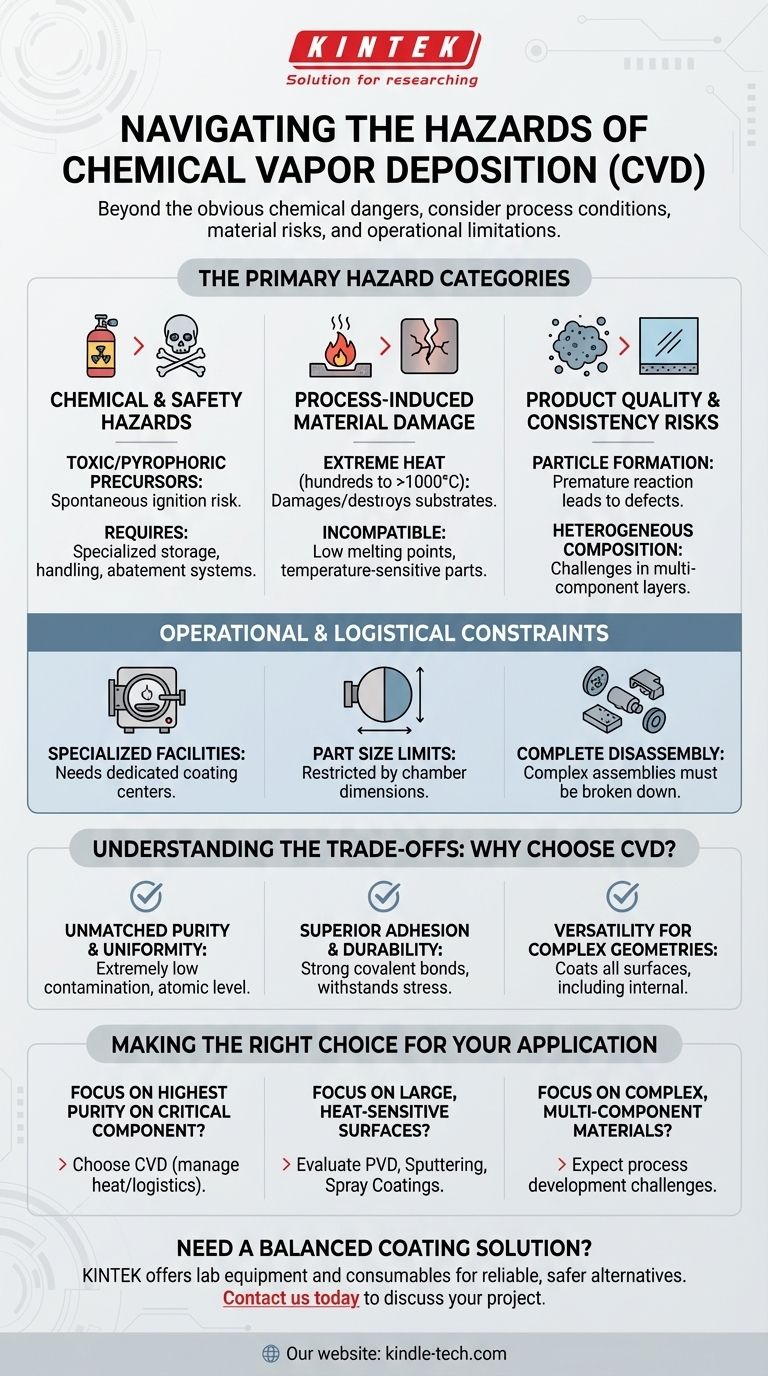

The Primary Hazard Categories

To fully assess the risks of CVD, we must look beyond just chemical safety and consider the hazards to your material, your process, and your project's outcome.

### Chemical and Safety Hazards

The most immediate danger in CVD comes from the precursor materials. Many CVD processes rely on gases that are toxic, flammable, corrosive, or even pyrophoric, meaning they can spontaneously ignite upon contact with air.

This necessitates highly specialized storage, handling protocols, delivery systems, and exhaust gas treatment (abatement) systems, all of which add complexity and cost. An absence of safe, non-toxic precursors for many applications is a fundamental challenge of the technology.

### Process-Induced Material Damage

CVD is often a high-temperature process, frequently operating at several hundred or even over a thousand degrees Celsius. This thermal load can damage or destroy the very substrate you intend to coat.

Materials with low melting points, specific heat treatments, or temperature-sensitive electronics are often incompatible with thermal CVD methods. This single factor can immediately disqualify CVD as a viable option for many applications.

### Product Quality and Consistency Risks

A significant operational hazard is the risk of producing a low-quality or inconsistent film. During deposition, precursor gases can react prematurely in the gas phase, forming hard aggregates or particles. These particles can incorporate into your film, creating defects and compromising material quality.

Furthermore, when creating films from multiple materials, slight differences in vapor pressure and reaction rates between precursors can lead to a heterogeneous composition. Achieving a perfectly uniform, multi-component layer is a significant engineering challenge.

Operational and Logistical Constraints

The practical realities of implementing CVD present another set of "hazards" to your project's timeline and budget. These are often as critical as the technical challenges.

### The Need for Specialized Facilities

CVD is not a portable process. It must be performed inside a dedicated vacuum chamber at a specialized coating center. This immediately introduces logistical hurdles of shipping and handling.

The size of the part you can coat is also strictly limited by the dimensions of the available vacuum chamber. Coating very large surfaces is often impractical or impossible with standard CVD equipment.

### Requirement for Part Disassembly

Because CVD is a non-line-of-sight process that coats all exposed surfaces, complex assemblies must be completely broken down into individual components before coating.

This adds significant labor costs and logistical complexity for both disassembly before the process and reassembly after. It also introduces the risk of damage or loss during this extensive handling.

Understanding the Trade-offs: Why Choose CVD Despite the Risks?

Given these significant hazards and constraints, the decision to use CVD is a matter of clear trade-offs. The process is chosen when its unique benefits are non-negotiable and outweigh the risks.

### Unmatched Purity and Uniformity

The core advantage of CVD is its ability to produce exceptionally high-purity thin films with excellent uniformity. Because the process is built from atomic or molecular precursors, the level of contamination can be kept extremely low.

### Superior Adhesion and Durability

The chemical reactions at the heart of CVD form a strong, covalent bond between the coating and the substrate. This results in highly durable and adherent layers that can withstand extreme stress and temperature variations.

### Versatility for Complex Geometries

Unlike line-of-sight processes (like Physical Vapor Deposition), the precursor gases in CVD can diffuse and coat all surfaces of a complex part evenly. This makes it ideal for coating the internal surfaces of intricate components, which is impossible with many other methods.

Making the Right Choice for Your Application

Your final decision must be guided by your primary technical and business goals.

- If your primary focus is achieving the highest purity and uniformity on a critical component: CVD is often the superior choice, provided you can manage the high temperatures and logistical requirements of disassembly.

- If your primary focus is coating large, simple surfaces or heat-sensitive materials: You should strongly evaluate alternative, lower-temperature processes like Physical Vapor Deposition (PVD), sputtering, or spray coatings.

- If your primary focus is synthesizing complex, multi-component materials with precise stoichiometry: Be prepared for significant process development challenges, as controlling the final composition is a known difficulty in CVD.

Ultimately, viewing CVD as a specialized, high-performance tool rather than a general-purpose solution is the key to leveraging its power successfully.

Summary Table:

| Hazard Category | Key Risks |

|---|---|

| Chemical & Safety | Toxic, flammable, or pyrophoric precursor gases requiring specialized handling. |

| Material Damage | Extreme process heat can damage or destroy temperature-sensitive substrates. |

| Product Quality | Risk of particle defects and inconsistent composition in multi-material films. |

| Operational Constraints | Limited by part size, requires disassembly, and specialized facility access. |

Need a coating solution that balances performance with safety? The hazards of CVD are significant, but the right equipment and expertise make all the difference. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable, safer alternatives and expert guidance. Let our specialists help you select the ideal deposition technology for your specific materials and application. Contact us today to discuss your project and ensure a successful, safe outcome!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition